17

|

Piping installation

Installer and user reference guide

63

FXFN50~112A2VEB

CO₂ Conveni-Pack: indoor unit

4P677925-1 – 2021.07

17.2.2 Precautions when connecting the refrigerant piping

INFORMATION

Also read the precautions and requirements in the following chapters:

▪

"2 General safety precautions"

▪

"17.1 Preparing refrigerant piping"

DANGER: RISK OF BURNING/SCALDING

CAUTION

NEVER bend high pressure piping! Bending can reduce the pipe thickness and thus

weaken the piping. ALWAYS use K65 fittings.

NOTICE

Take the following precautions on refrigerant piping into account:

▪

Avoid anything but the designated refrigerant to get mixed into the refrigerant

cycle (e.g. air).

▪

Only use R744 (CO₂) when adding refrigerant.

▪

Only use installation tools (e.g. manifold gauge set) that are exclusively used for

R744 (CO₂) installations to withstand the pressure and to prevent foreign

materials (e.g. mineral oils and moisture) from entering the system.

▪

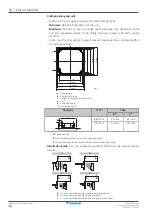

Do NOT leave pipes unattended at the site. If you will finish the work in less than

1 month, tape the pipe ends or pinch the pipe (see figure below). Pipes that are

installed outdoors must be pinched, regardless of the duration of the works.

▪

Use caution when passing copper tubes through walls (see figure below).

INFORMATION

Do NOT open the refrigerant stop valve before checking the refrigerant piping. When

you need to charge additional refrigerant it is recommended to open the refrigerant

stop valve after charging.

17.2.3 Guidelines when connecting the refrigerant piping

▪

When brazing, blow through with nitrogen to prevent creation of large quantities

of oxidized film on the inside of the piping. This film adversely affects valves and

compressors in the refrigerating system and prevents proper operation.

Summary of Contents for FXFN112A2VEB

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ...4P677925 1 2021 07 Copyright 2021 Daikin Verantwortung für Energie und Umwelt ...