17

|

Piping installation

Installer and user reference guide

64

FXFN50~112A2VEB

CO₂ Conveni-Pack: indoor unit

4P677925-1 – 2021.07

▪

Set the nitrogen pressure to 20 kPa (0.2 bar) (just enough so it can be felt on the

skin) with a pressure-reducing valve.

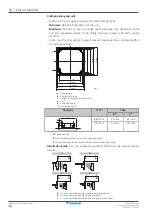

a

b

c

d

e

f

f

a

Refrigerant piping

b

Part to be brazed

c

Taping

d

Manual valve

e

Pressure-reducing valve

f

Nitrogen

▪

Do NOT use anti-oxidants when brazing pipe joints.

Residue can clog pipes and break equipment.

▪

Do NOT use flux when brazing copper-to-copper refrigerant piping. Use phosphor

copper brazing filler alloy (CuP279, CuP281, or CuP284:DIN EN ISO 17672), which

does not require flux.

Flux has an extremely harmful influence on refrigerant piping systems. E.g., if a

chlorine-based flux is used, it will cause pipe corrosion or, in particular, if the flux

contains fluorine, it will deteriorate the refrigerant oil.

▪

Always protect the surrounding surfaces (e.g. using insulation foam) against heat

when brazing.

17.2.4 To connect the refrigerant piping to the indoor unit

CAUTION

Install the refrigerant piping or components in a position where they are unlikely to

be exposed to any substance which may corrode components containing refrigerant,

unless the components are constructed of materials that are inherently resistant to

corrosion or are suitably protected against corrosion.

▪

Pipe length

. Keep refrigerant piping as short as possible.

WARNING

▪

Use K65 piping for high-pressure applications with a working pressure of 120 bar

or 90 bar, depending on its location in the system.

▪

Use K65 unions and fittings approved for a working pressure of 120 bar or 90 bar,

depending on its location in the system.

▪

ONLY brazing is allowed for connection of pipes. No other types of connections

are allowed.

▪

Expanding of pipes is NOT allowed.

1

Insert the field pipe into the piping on the indoor unit side.

2

Connect refrigerant piping to the unit using only

brazed connections

.

NOTICE

When brazing, cover the plastic hold plate (d) and thermal insulation (e) by a wet

cloth and make sure the temperature does not exceed 200°C.

Summary of Contents for FXFN112A2VEB

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ...4P677925 1 2021 07 Copyright 2021 Daikin Verantwortung für Energie und Umwelt ...