12

thermostat calls for heat. At the end of the timing period,

the unit’s defrost cycle will be initiated provided the sensor

remains closed. When the sensor opens (approximately 60

± 5°F), the defrost cycle is terminated and the timing period

is reset. If the defrost cycle is not terminated due to the

sensor temperature, a twelve minute override interrupts the

unit’s defrost period.

SUGGESTED FIELD TESTING/TROUBLE

SHOOTING

Testing Defrost Control

NOTE: PCBDM133 defrost controls have a three (3)

minute compressor off cycle delay.

NOTE: The PCBDM133 defrost controls are shipped

from the factory with the compressor delay option

selected. This will de-energize the compressor

contactor for 30 seconds on defrost initiation and

defrost termination. If the jumper is set to Normal,

the compressor will continue to run during defrost

initiation and defrost termination. The control will

also ignore the low-pressure switch connected to

R-PS1 and PS2 for 5 minutes upon defrost initiation

and 5 minutes after defrost termination.

To check the defrost control for proper sequencing,

proceed as follows: With power ON; unit not running.

1. Jumper defrost thermostat by placing a jumper wire

across the terminals “DFT” and “R”/” R-DFT” at

defrost control board.

2. Remove jumper from timer pins and jump across test

pins on defrost control board.

NOTE:

Do not use screwdriver or field supplied

jumper to test the control.

3. Set thermostat to call for heating. System should go

into defrost within 21 seconds.

4. Immediately remove jumper from test pins.

5. Using VOM check for voltage across terminals “C &

O”. Meter should read 24 volts.

6. Using VOM check for voltage across fan terminals

DF1 and DF2 on the board. Should read line voltage

(208-230 VAC) indicating the relay is open in the

defrost mode.

7. Using VOM check for voltage across “W”/”W2” & “C”

terminals on the board. Should read 24 volts.

8. If not as above, replace control board.

9. Set thermostat to off position and disconnect power.

Remove jumper from defrost thermostat and replace

timer jumper to the desired defrost time.

NOTE: Remove jumper across defrost thermostat

before returning system to service. See figure 11 -

Defrost Control Wiring Diagram.

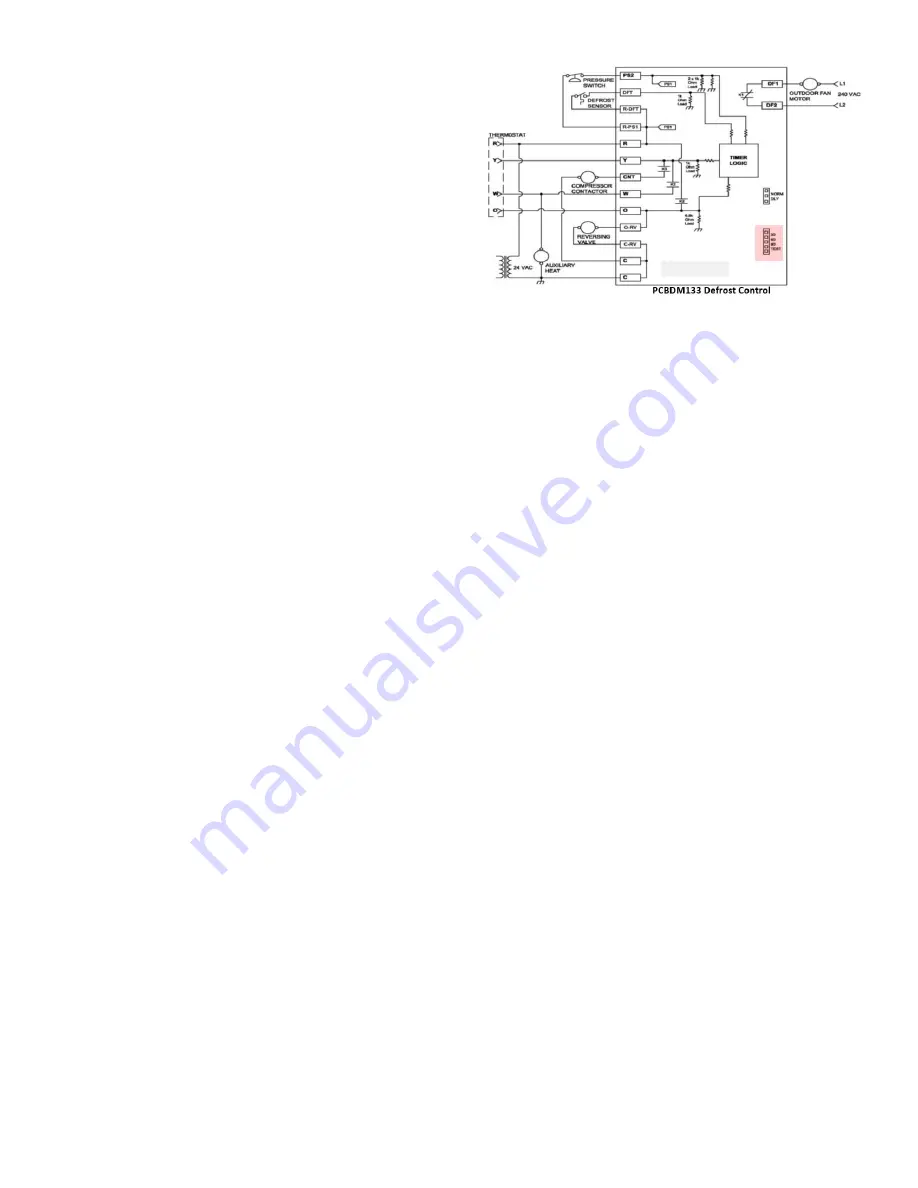

Defrost Control Wiring Schematic

Figure 11

Testing Defrost Thermostat

1.

Install a thermocouple type temperature test lead on

the tube adjacent to the defrost control. Insulate the

lead point of contact.

2. Check the temperature at which the control closes its

contacts by lowering the temperature of the control. It

should close at approximately 30°F.

3. Check the temperature at which the control opens its

contacts by raising the temperature of the control. It

should open at approximately 60°F. If not as above,

replace control.

AIR FLOW MEASUREMENT AND

ADJUSTMENT

Please review the

Duct Work

section before

proceeding with the airflow measurements and

adjustments in this section.

Unit blower curves (see Specification Sheets) are based

on external static pressure (ESP per in/W.C.). The

duct openings on the unit are considered internal static

pressure. As long as ESP is maintained, the unit will deliver

the proper air up to the maximum static pressure listed for

the CFM required by the application (i.e. home, building,

etc.).

In general, 400 CFM per ton of cooling capacity is a rule

of thumb. Some applications depending on the sensible

and latent capacity requirements may need only 350

CFM or up to 425 CFM per ton. Check condition space

load requirements (from load calculations) and equipment

expanded ratings data to match CFM and capacity.

After unit is set and duct work completed, verify the ESP

with a 1-inch inclined manometer with pilot tubes or a

Magnahelic gauge and confirm CFM to blower curves in

the Specification Sheets. All units have multiple speed

blower motors. If factory selected speed is not utilized, the

speed tap can be changed.