Installation manual

4

EWWQ014~064KBW1N

Packaged water-cooled water chillers

D-EIMHP00908-17EU

P

IPING

INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation and reduction of the cooling capacity.

Protect the water piping against water freezing during winter period

(e.g. by using a glycol solution or heatertape).

F

IELD

WIRING

Parts table

F1,2,3 .....................Main fuses for the unit

H3P ........................Indication lamp alarm

H4P, H5P ................Indication lamp operation compressor circuit 1,

circuit 2

PE ..........................Main earth terminal

S7S ........................Remote cooling/heating change-over valve or

dual setpoint

S9S ........................Remote start/stop switch or dual setpoint

- - -..........................Field wiring

Power circuit and cable requirements

1

The electrical power supply to the unit must be arranged so that

it can be switched on or off independently of the electrical supply

to other items of the plant and equipment in general.

2

A power circuit must be provided for connection of the unit. This

circuit must be protected with the required safety devices, i.e. a

circuit breaker, a slow blow fuse on each phase and an earth

leak detector. Recommended fuses are mentioned on the wiring

diagram supplied with the unit.

Connection of the water-cooled water chiller power

supply

1

Using the appropriate cable, connect the power circuit to the N,

L1, L2 and L3 terminals of the unit (cable section 2.5~10 mm

2

).

2

Connect the earth conductor (yellow/green) to the earthing

terminal PE.

Point for attention regarding quality of the public

electric power supply

■

This equipment complies with EN/IEC 61000-3-11

(1)

provided

that the system impedance Z

sys

is less than or equal to Z

max

at

the interface point between the user's supply and the public

system. It is the responsibility of the installer or user of the

equipment to ensure, by consultation with the distribution

network operator if necessary, that the equipment is connected

only to a supply with a system impedance Z

sys

less than or

equal to Z

max

.

■

Only for EWWQ014~064: Equipment complying with

EN/IEC 61000-3-12

(2)

Interconnection cables

■

Voltage free contacts

The PCB is provided with some voltage free contacts to indicate

the status of the unit. These voltage free contacts can be wired

as described on the wiring diagram.

■

Remote inputs

Besides the voltage free contacts, there are also possibilities to

install remote inputs.

They can be installed as shown on the wiring diagram.

B

EFORE

STARTING

The water pressure should not exceed the maximum

working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit to

make sure that the water pressure will never exceed

the maximum allowable working pressure.

All field wiring and components must be installed by a

licensed electrician and must comply with relevant Euro-

pean and national regulations.

The field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

Be sure to use a dedicated power circuit. Never use a

power supply shared by another appliance.

Switch off the main isolator switch before making any

connections (switch off the circuit breaker, remove or

switch off the fuses).

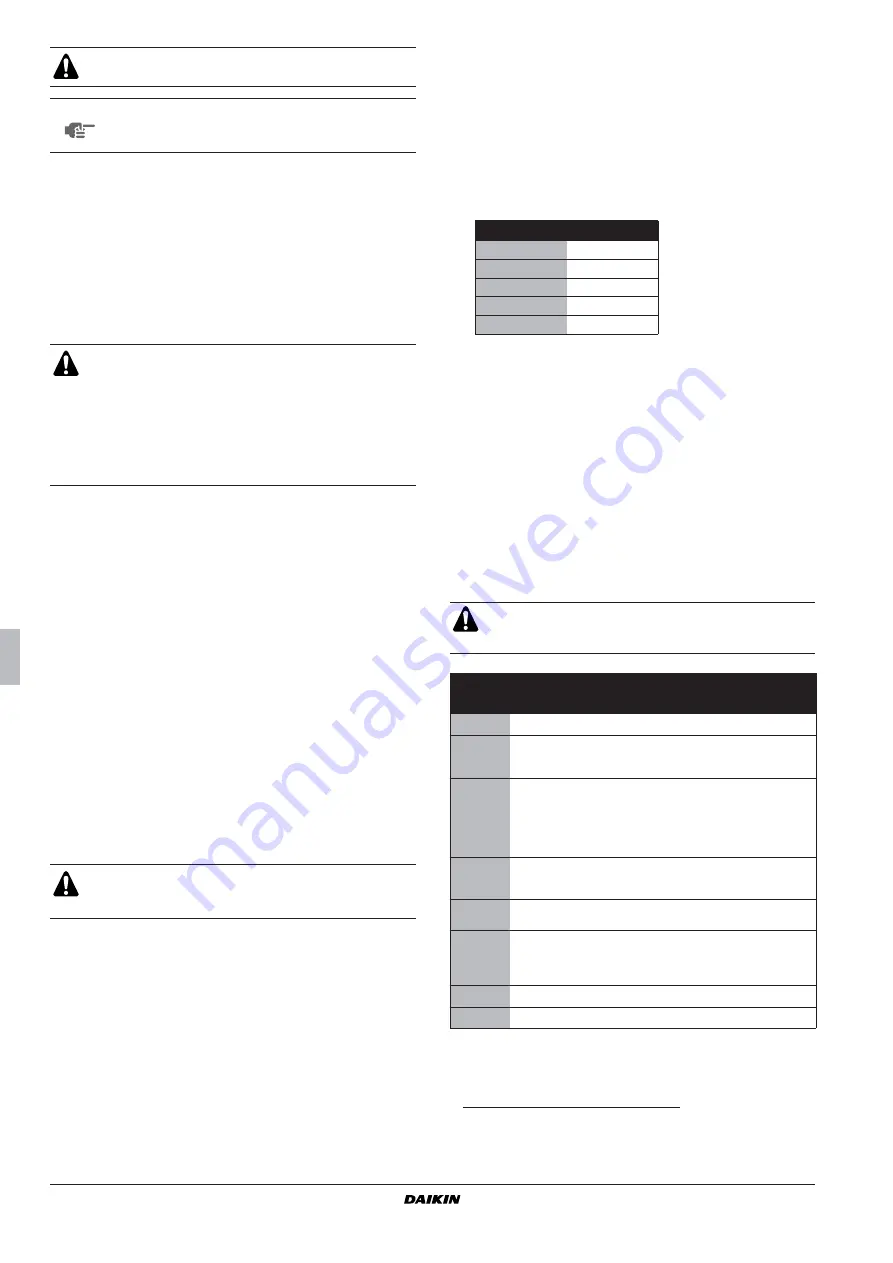

(1) European/International Technical Standard setting the limits for voltage

changes, voltage fluctuations and flicker in public low-voltage supply

systems for equipment with rated current

≤

75 A.

Z

max

(

Ω

)

EWWQ014

0.28

EWWQ025

0.23

EWWQ033

0.21

EWWQ049

0.22

EWWQ064

0.20

(2) European/International Technical Standard setting the limits for harmonic

currents produced by equipment connected to public low-voltage systems

with input current >16 A and

≤

75 A per phase.

The unit should not be started, not even for a very short

period of time, before the following pre-commissioning

checklist is filled out completely.

tick

✓

when

checked

standard steps to go through before starting the unit

■

1

Check for external damage.

■

2

Install main fuses, earth leak detector and main switch.

Recommended fuses: aM according to IEC standard 269-2.

Refer to the wiring diagram for size.

■

3

Supply the main voltage and check if it is within the allowable

±10% limits of the nameplate rating.

The electrical main power supply must be arranged so, that it

can be switched on or off independently of the electrical supply

to other items of the plant and equipment in general.

Refer to the wiring diagram, terminals N, L1, L2 and L3.

■

4

Supply water to the evaporator and verify if waterflow is within

the limits as given in the table under "Water charge, flow and

quality" on page 3.

■

5

The piping must be completely purged. See also chapter

"Checking the water circuit" on page 2.

■

6

Connect the flowswitch and pumpcontact, so that the unit

can only come in operation when the waterpumps are running

and the waterflow is sufficient. Make sure a water filter is

installed before the water inlet of the unit.

■

7

Connect the optional field wiring for pumps start-stop.

■

8

Connect the optional field wiring for remote control.

Summary of Contents for HYDROCUBE EWWQ014KBW1N

Page 2: ......

Page 45: ...EWWQ KB DAIKIN EUROPE V Hz A 41 7 bar kg R410A R410A...

Page 57: ...EWWQ KB DAIKIN 41 7 R410A R410A...

Page 58: ...NOTES...

Page 59: ...NOTES...

Page 60: ...D EIMHP00908 17EU...