I

nsTallaTIon

www.DaikinApplied.com

5

IM 1093-1 • SINGLE DUCT VAV TERMINALS

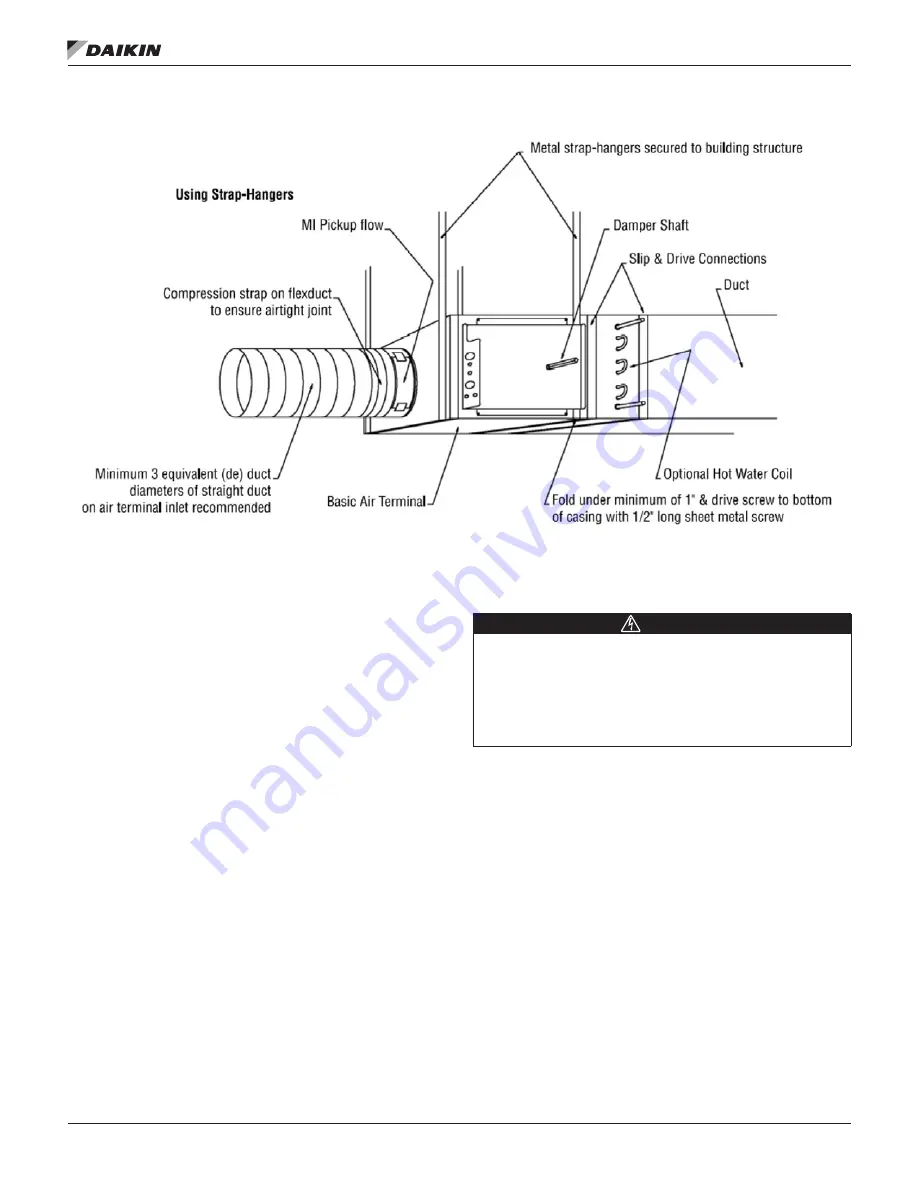

Figure 2: Trapeze-Hangers

Minimum Clearance for Access

Single Duct Air Terminals require sufficient to allow servicing

of the actuator, controls and single electric power hook-

up (if applicable). Horizontal clearance requirements are

dependent upon access panel dimensions which are

indicated on the appropriate submittals (for control panel

enclosure access a minimum of 18" is recommended. See the

appropriate submittal for control panel location). NOTE: These

clearance recommendations are not meant to preclude NEC

requirements or local building codes.

Connecting Ductwork

Slip each inlet duct over the inlet collar of the terminal. Fasten

and seal the connection by the method prescribed by the job

specification. The diameter of the inlet duct “D” in inches must

be equal to the listed size of the terminal; e.g. a duct that

actually measures 8 inches must be fitted to a size 8 terminal.

The inlet collar of the terminal is made 1/8 inch smaller than

listed size in order to fit inside the duct.

NOTE:

Do not insert duct work inside the inlet collar of the

assembly.

Inlet duct should be installed in accordance with SMACNA

guidelines. If a single point electronic velocity sensor is

installed, it is recommended that the installer provide three to

five diameters of straight duct at the terminal inlet. The outlet

end of the terminal is designed for use with slip and drive duct

connections (flanged outlets optional). A rectangular duct the

size of the terminal outlet should be attached.

Field Electrical Wiring

DANGER

Electric shock hazard . Can cause personal injury or

equipment damage .

This equipment must be properly grounded. Connections and

service to the MicroTech III Chiller Unit Controller must be

performed only by personnel knowledgeable in the operation

of the equipment being controlled.

•

All field wiring must comply with the local codes and with

the National Electrical Code (ANSI/NFPA 70-2002).

•

When applicable, electrical, control and piping diagrams

are shown on labels attached to the exterior of the single

duct unit.

• Use copper conductors only!

•

All terminal units must be properly grounded per NEC

424-14 and 250.

•

Always check product label for voltage and current data

to determine the proper wire size and current protection.

• The control cabinet contains live electrical parts!

Contacting these parts with the power applied may cause

serious injury or death. The control cover must be closed

prior to applying electric power to the unit.

• These recommendations are not meant to preclude

NEC requirements or local building codes that may be

applicable, which are the responsibility of the installing

contractor.