T

roubleshooTIng

www.DaikinApplied.com

7

IM 1093-1 • SINGLE DUCT VAV TERMINALS

T

roubleshooTIng

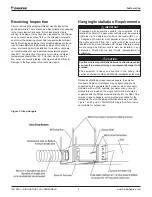

Investigating Noise Complaints

Noise from a terminal can be due to a variety of conditions, and

can be difficult to eliminate. The first step is to isolate the type,

source and direction. Generally, noise heard at the air outlet is

considered a discharge type. Noise heard through the ceiling is

considered a radiated noise. For detailed information concerning

noise transmission in buildings see ARI Standard 885-2008E,

titled

Procedure For Estimating Occupied Space Sound Levels

In The Application Of Air Terminals and Air Outlets.

Discharge Noise

Discharge noise is usually caused by high static or little

to no internal duct lining downstream of the terminal. It

can sometimes be caused by the air outlet itself. Air outlet

generated sounds can be reduced by reducing flow or

increasing air outlet size. Reducing static pressure, or flow, or

adding additional attenuation materials will reduce discharge

sounds from the terminal unit. Sometimes, moving the flex duct

between the terminal and air outlet so the air must make an

additional turn will help with the discharge sound.

Radiated Noise

Radiated noise is most commonly associated with fan powered

terminal units.

Controls

DANGER

Electric shock hazard . Can cause personal injury or

equipment damage .

This equipment must be properly grounded. Connections and

service to the MicroTech III Chiller Unit Controller must be

performed only by personnel knowledgeable in the operation

of the equipment being controlled.

CAUTION

Static sensitive components . Can cause equipment

damage .

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

Contact your Daikin representative for information concerning

controls provided by Daikin. For controls provided by others,

contact the local control representative for assistance.

Electric Duct Heater

DANGER

Electric shock hazard . Can cause personal injury or

equipment damage .

This equipment must be properly grounded. Connections and

service to the MicroTech III Chiller Unit Controller must be

performed only by personnel knowledgeable in the operation

of the equipment being controlled.

• If the heater does not operate:

—

Check electric power into the unit, and verify that the

wiring agrees with the label diagram located on the

terminal unit casing.

—

Verify that the unit is installed properly (i.e., according

to the air flow orientation label). Review the wiring

diagram supplied with the heater to verify the field

wiring is correct and of the proper gauge and that the

heater is properly grounded.

• If the heater cycles on and off:

—

Verify that the airflow is uniformly distributed across

the face of the heater. Check for obstructions in

the duct, or insufficient air flow (CFM) (see label for

minimum CFM).

• If conditioned space fails to warm-up:

—

Make certain that the heater controls and the

thermostat are compatible and wired properly.

Relocate the thermostat if it is located in a position

that is too warm.

• If conditioned space overheats:

—

Make certain that the heater controls and the

thermostat are compatible and wired properly.

Relocate the thermostat if it is located in a position

that is too cool. Verify that the air distribution to the

space is appropriate for the required thermal load.