Specifications

EDUS041016

6

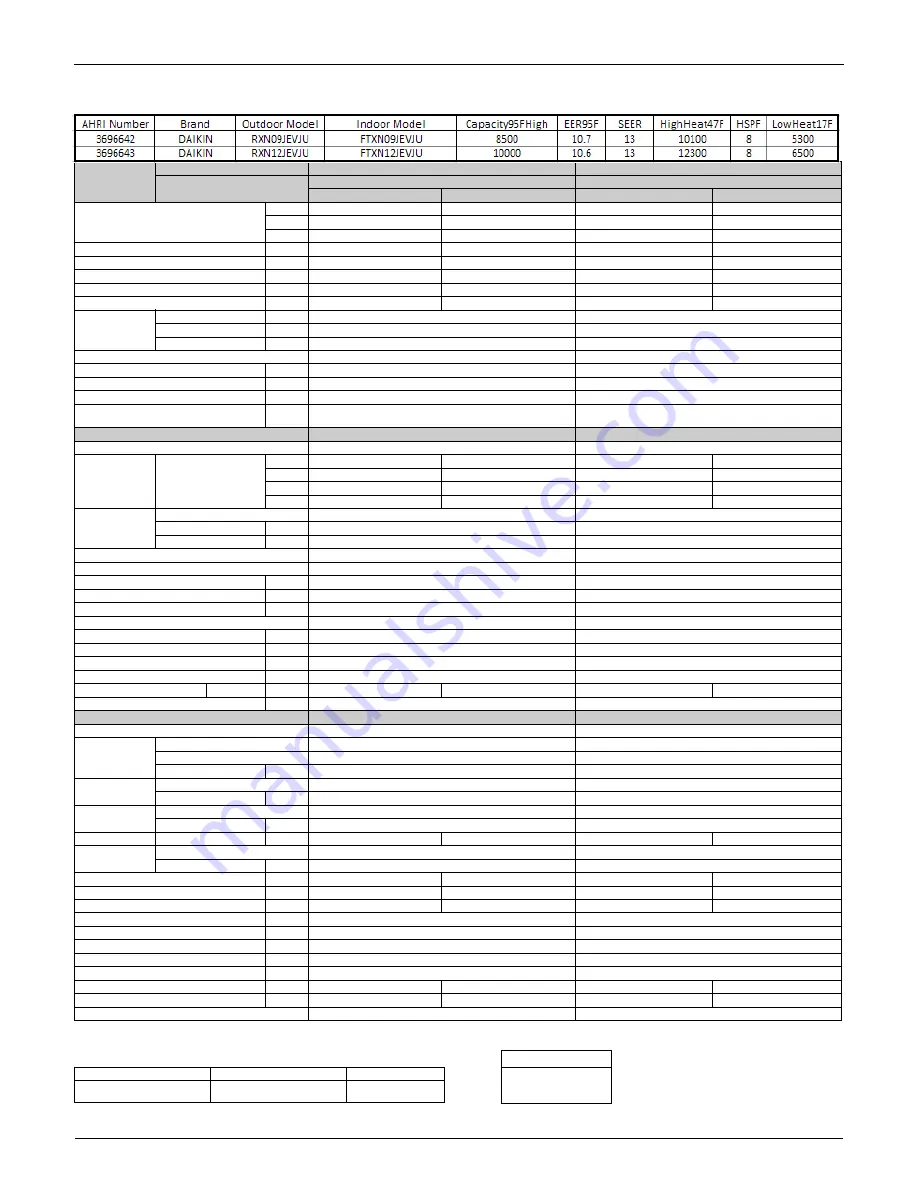

Room Air Conditioners J-Series

3.2

Heat Pump

The data are based on the conditions shown in the table below.

Models

60Hz 208-230V

Indoor Units

FTXN09JEVJU

FTXN12JEVJU

Outdoor Units

RXN09JEVJU

RXN12JEVJU

Cooling

Heating

Cooling

Heating

Capacity

Rated (Min.~Max.)

kW

2.49 (1.30~2.78)

2.93 (1.3~3.4)

2.93 (1.3~3.52)

3.52 (1.3~4.8)

Btu/h

8,500 (4,400~9,500)

10,000 (4,400~11,600)

10,000 (4,400~12,000)

12,000 (4,400~16,400)

kcal/h

2,140 (1,120~2,390)

2,520 (1,120~2,920)

2,520 (1,120~3,030)

3,030 (1,120~4,130)

Running Current (Rated)

A

4.6-4.1

4.6-4.2

4.8-4.4

5.4-4.9

Power Consumption Rated (Min.~Max.)

W

795 (330~890)

865 (320~930)

945 (330~1,310)

1,050 (320~1,650)

Power Factor

%

83.1-84.3

90.4-89.5

94.7-93.4

93.5-93.2

COP (Rated) (Min.~Max.)

W/W

3.13 (3.94~3.12)

3.39 (4.06~3.66)

3.10 (3.94~2.69)

3.35 (4.06~2.91)

EER (Rated) (Min.~Max.)

Btu/h·W

10.69 (13.33~10.67)

11.56 (13.75~12.47)

10.58 (13.33~9.16)

11.43 (13.75~9.94)

Piping

Connections

Liquid

inch

1/4

1/4

Gas

inch

3/8

3/8

Drain

inch

5/8

5/8

Heat Insulation

Both Liquid and Gas Pipes

Both Liquid and Gas Pipes

Max. Interunit Piping Length

feet

49.2

49.2

Max. Interunit Height Difference

feet

39.3

39.3

Chargeless

feet

32.8

32.8

Amount of Additional Charge of

Refrigerant

oz/ft

0.22

0.22

Indoor Units

FTXN09JEVJU

FTXN12JEVJU

Front Panel Color

White

White

Airflow Rate

m³/min (cfm)

H

9.2 (325)

9.7 (342)

9.3 (328)

10.1 (357)

M

7.4 (261)

8.1 (286)

7.7 (272)

8.4 (297)

L

5.3 (187)

6.4 (226)

5.6 (198)

6.7 (237)

SL

4.0 (141)

5.6 (198)

4.4 (155)

5.9 (208)

Fan

Type

Cross Flow Fan

Cross Flow Fan

Motor Output

W

16

16

Speed

Steps

5 Steps, Quiet, Auto

5 Steps, Quiet, Auto

Air Direction Control

Right, Left, Horizontal, Downward

Right, Left, Horizontal, Downward

Air Filter

Removable / Washable / Mildew Proof

Removable / Washable / Mildew Proof

Running Current (Rated)

A

0.20-0.18

0.20-0.18

Power Consumption (Rated)

W

40

40

Power Factor

%

96.2-96.6

96.2-96.6

Temperature Control

Microcomputer Control

Microcomputer Control

Dimensions (H

×

W

×

D)

inch

11-9/64

×

30-5/16

×

7-51/64

11-9/64

×

30-5/16

×

7-51/64

Packaged Dimensions (H

×

W

×

D)

inch

10-17/64

×

33-7/32

×

13-15/32

10-17/64

×

33-7/32

×

13-15/32

Weight

Lbs

16

16

Gross Weight

Lbs

24

24

Operation Sound

H/M/L/SL

dBA

40 / 33 / 26 / 22

40 / 34 / 28 / 25

41 / 34 / 27 / 23

41 / 35 / 29 / 26

Sound Power

dBA

56

57

Outdoor Units

RXN09JEVJU

RXN12JEVJU

Casing Color

Ivory White

Ivory White

Compressor

Type

Hermetically Sealed Swing Type

Hermetically Sealed Swing Type

Model

1YC23AEXD

1YC23AEXD

Motor Output

W

750

750

Refrigerant Oil

Type

FVC50K

FVC50K

Charge

oz

12.5

12.5

Refrigerant

Type

R-410A

R-410A

Charge

Lbs

2.20

2.20

Airflow Rate

m³/min (cfm)

H

29.0 (1,024)

28.1 (992)

29.0 (1,024)

28.1 (992)

Fan

Type

Propeller

Propeller

Motor Output

W

59

59

Running Current (Rated)

A

4.40-3.92

4.40-4.02

4.60-4.22

5.20-4.72

Power Consumption (Rated)

W

755

825

905

1,010

Power Factor

%

82.5-83.7

90.1-89.2

94.6-93.2

93.4-93.0

Starting Current

A

4.6

5.4

Dimensions (H

×

W

×

D)

inch

21-21/32

×

25-29/32

×

10-13/16

21-21/32

×

25-29/32

×

10-13/16

Packaged Dimensions (H

×

W

×

D)

inch

23-5/16

×

30-23/64

×

13-45/64

23-5/16

×

30-23/64

×

13-45/64

Weight

Lbs

68

68

Gross Weight

Lbs

78

78

Operation Sound

dBA

49

50

50

51

Sound Power

dBA

63

64

64

65

Drawing No.

3D066712

3D066713

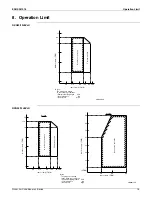

Cooling

Heating

Piping Length

Indoor ; 80°FDB/67°FWB

Outdoor ; 95°FDB/75°FWB

Indoor ; 70°FDB/60°FWB

Outdoor ; 47°FDB/43°FWB

25 ft

Conversion Formulae

kcal/h=kW

×

860

Btu/h=kW

×

3412

cfm=m

³

/min

×

35.3

Summary of Contents for J Series

Page 1: ...EDUS041016 J Series Cooling Only Heat Pump SEER 13 Models ...

Page 53: ...Operation Manual EDUS041016 52 Room Air Conditioners J Series 12 2 Operation Instructions ...

Page 54: ...EDUS041016 Operation Manual Room Air Conditioners J Series 53 ...

Page 55: ...Operation Manual EDUS041016 54 Room Air Conditioners J Series ...

Page 56: ...EDUS041016 Operation Manual Room Air Conditioners J Series 55 ...

Page 57: ...Operation Manual EDUS041016 56 Room Air Conditioners J Series ...

Page 58: ...EDUS041016 Operation Manual Room Air Conditioners J Series 57 ...

Page 59: ...Operation Manual EDUS041016 58 Room Air Conditioners J Series ...

Page 60: ...EDUS041016 Operation Manual Room Air Conditioners J Series 59 ...

Page 61: ...Operation Manual EDUS041016 60 Room Air Conditioners J Series ...

Page 62: ...EDUS041016 Operation Manual Room Air Conditioners J Series 61 ...

Page 63: ...Operation Manual EDUS041016 62 Room Air Conditioners J Series ...

Page 64: ...EDUS041016 Operation Manual Room Air Conditioners J Series 63 ...

Page 65: ...Operation Manual EDUS041016 64 Room Air Conditioners J Series ...

Page 66: ...EDUS041016 Operation Manual Room Air Conditioners J Series 65 ...

Page 67: ...Operation Manual EDUS041016 66 Room Air Conditioners J Series ...

Page 68: ...EDUS041016 Operation Manual Room Air Conditioners J Series 67 ...

Page 69: ...Operation Manual EDUS041016 68 Room Air Conditioners J Series ...

Page 70: ...EDUS041016 Operation Manual Room Air Conditioners J Series 69 ...

Page 71: ...Operation Manual EDUS041016 70 Room Air Conditioners J Series ...

Page 72: ...EDUS041016 Operation Manual Room Air Conditioners J Series 71 ...

Page 73: ...Operation Manual EDUS041016 72 Room Air Conditioners J Series ...

Page 74: ...EDUS041016 Operation Manual Room Air Conditioners J Series 73 ...

Page 75: ...Operation Manual EDUS041016 74 Room Air Conditioners J Series ...

Page 76: ...EDUS041016 Operation Manual Room Air Conditioners J Series 75 ...

Page 77: ...Operation Manual EDUS041016 76 Room Air Conditioners J Series 3P253185 2 ...