15

|

Piping installation

Installer and user reference guide

95

LREN8~12A7 + LRNUN5A7

CO₂ ZEAS outdoor unit and capacity up unit

4P704142-1 – 2022.08

6

It is recommended to apply 20 PTFE tape windings onto the thread of the

threaded piece.

7

It is recommended to screw the safety valve onto the threaded piece and

tighten it between 35 and 60 N•m. The safety valve has to be installed

vertically so water cannot enter the blow-off hole.

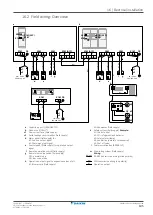

About changeover valves

In a configuration with 1 safety valve, it is necessary to evacuate the refrigerant if

the safety valve has to be replaced.

If you do not want to evacuate the refrigerant, we suggest you install a changeover

valve and use 2 safety valves.

System layout

d

a a

b

c

a

Safety valve (1 acc 1 field supplied)

b

Changeover valve (field supplied)

c

Threaded piece (accessory)

d

Outdoor unit

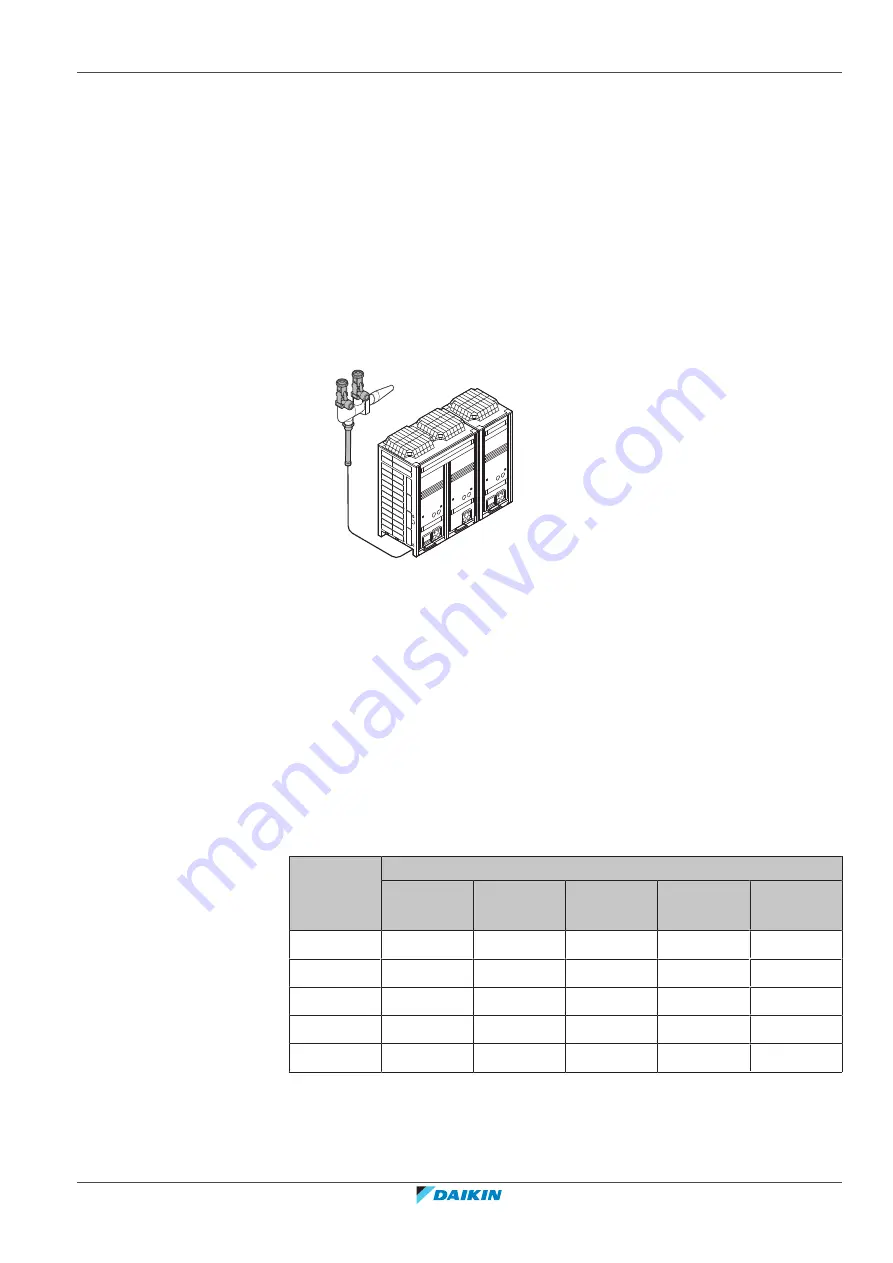

Safety valve reference information

Take the folllowing safety valve reference information into account.

Maximum piping length

The allowed length of the safety valve piping is limited by the following elements:

▪

the pipe's diameter

▪

the number of elbows in the piping

▪

the presence of a changeover valve and its kv value. For more information on

changeover valves, see

95].

Changeover

valve's kV

value

Maximum piping length (m) for Ø19.1 mm

(a)

8

elbows

9

elbows

10

elbows

11

elbows

12

elbows

0

(b)

21

20

20

19

18

3-3,49

14

13

12

12

11

3,5-4,49

15

15

14

14

13

4,5-4,99

17

17

16

16

15

5-7,99

18

17

17

16

16

(a)

K65 or equivalent piping

(b)

0 = There is no changeover valve present