15

|

Piping installation

Installer and user reference guide

96

LREN8~12A7 + LRNUN5A7

CO₂ ZEAS outdoor unit and capacity up unit

4P704142-1 – 2022.08

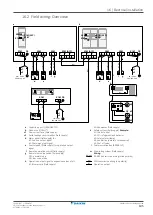

Changeover

valve's kV

value

Maximum piping length (m) for Ø 22.2

(a)

8

elbows

9

elbows

10

elbows

11

elbows

12

elbows

0

(b)

25

24

24

23

22

3-3,49

16

15

15

14

13

3,5-4,49

18

18

17

16

16

4,5-4,99

21

20

19

19

18

5-7,99

22

21

20

19

19

(a)

K65 or equivalent piping

(b)

0 = There is no changeover valve present

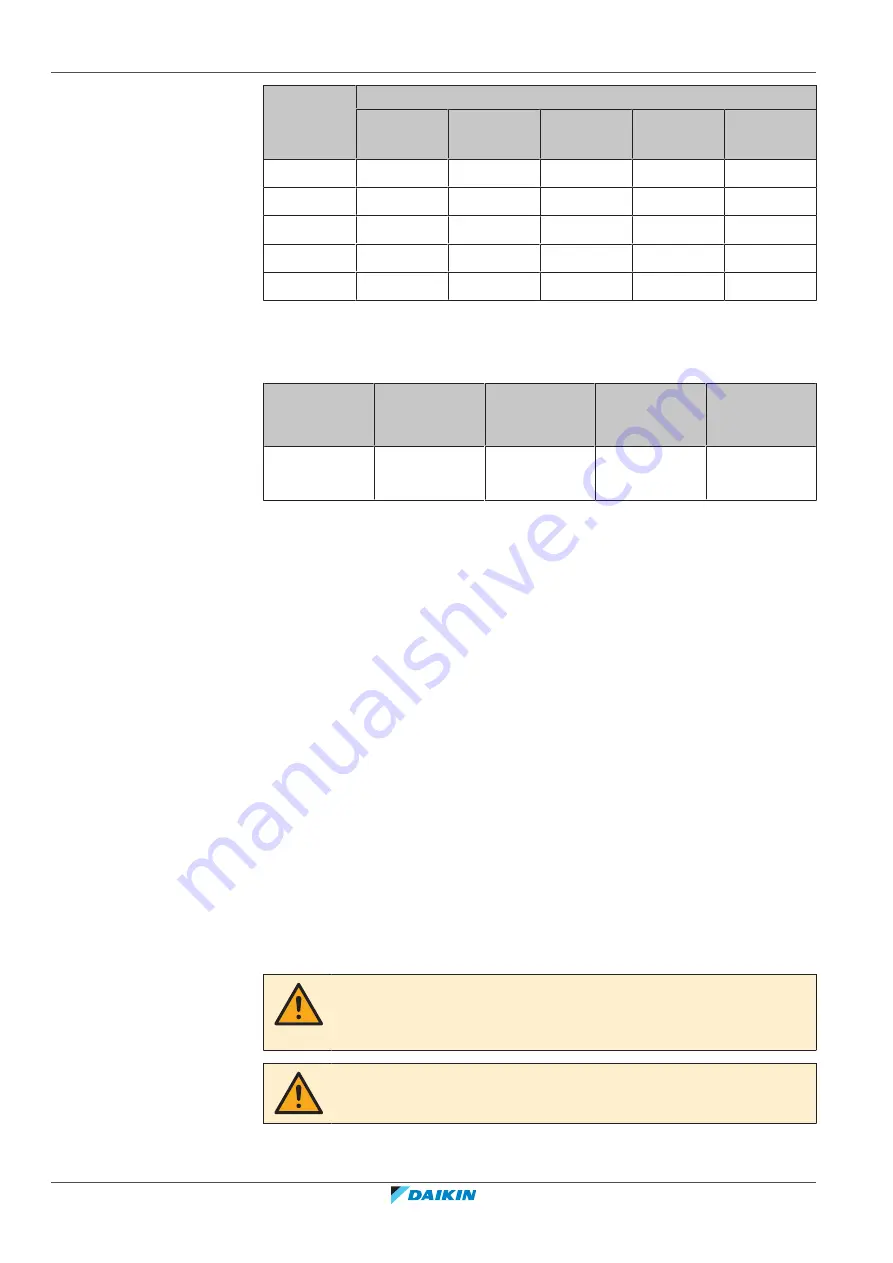

Specifications safety valve

PS

Kd

Flow area

Connection

Allowable

temperature

range

90 bar

0.90

15.9 mm

2

1/2" NPT in

1/2" G out

-50/+150°C

15.3.10 Guidelines to install blow-off piping

The installer has to install the blow-off piping.

▪

Install the outlet of the blow-off piping horizontally (for example, to prevent rain

dripping in). Never point the piping outlet downwards.

▪

Direct the outlet of the blow-off pipe to a location where blown off residue

cannot hurt or harm people or items.

▪

Calculate the maximum piping length according to standard EN 13136.

▪

Thread type must be G1 according to standard ISO 228.

15.4 Checking the refrigerant piping

Keep the following in mind:

▪

The test has to include the safety valve piping. It is therefore necessary that the

pressure passes through the unit. Always keep both liquid and gas stop valves

open during leak test and vacuum drying of the field piping.

▪

Only use R744 dedicated tools (such as gauge manifold and charge hose) that are

designed to withstand high pressures and which will prevent water, dirt or dust

entering the unit.

CAUTION

Do NOT open the stop valve until you have measured the insulation resistance of the

main power supply circuit.

CAUTION

ALWAYS use nitrogen gas for leak tests.