15

|

Piping installation

Installer and user reference guide

97

LREN8~12A7 + LRNUN5A7

CO₂ ZEAS outdoor unit and capacity up unit

4P704142-1 – 2022.08

15.4.1 About checking the refrigerant piping

15.4.2 Checking refrigerant piping: General guidelines

Connect the vacuum pump through a manifold to the service port of all stop valves

to increase efficiency (refer to

"15.4.3 Checking refrigerant piping: Setup"

NOTICE

Use a 2-stage vacuum pump with a non-return valve or a solenoid valve that can

evacuate to a gauge pressure of –100.7 kPa (−1.007 bar).

NOTICE

Make sure the pump oil does not flow oppositely into the system while the pump is

not working.

NOTICE

Do NOT purge the air with refrigerants. Use a vacuum pump to evacuate the

installation.

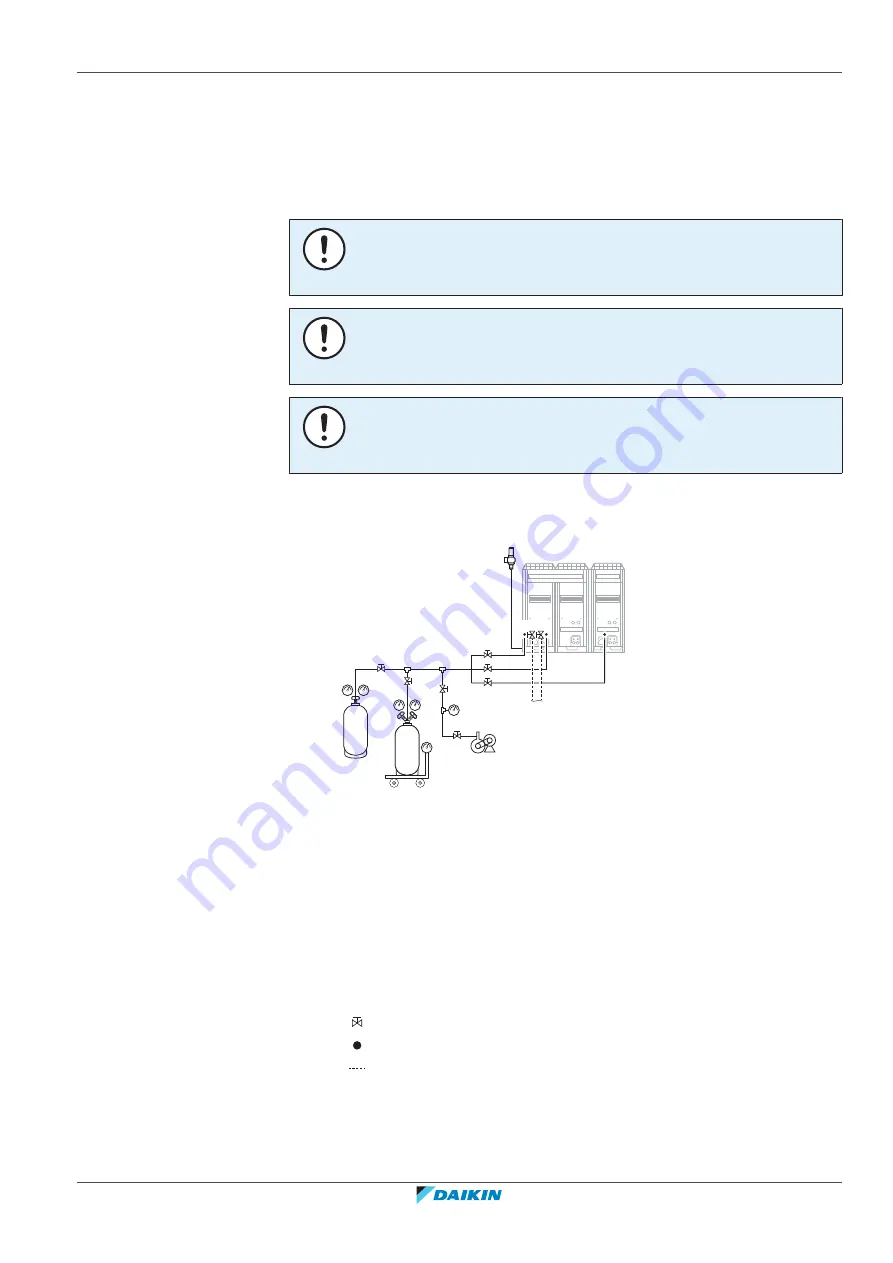

15.4.3 Checking refrigerant piping: Setup

E

a

N2

R744

a

b

b

C

A

B

D

ch id

e

g

b

f

A

Nitrogen (N

2

)

B

R744 refrigerant tank

C

Weighing scales

D

Vacuum pump

E

Outdoor unit

a

Pressure regulator

b

Charge hose

c

Service port SP3 (gas side)

d

Service port SP7 (liquid side)

e

Service port SP11 (gas side)

f

To refrigeration indoor unit

g

Safety valve

h

Stop valve (gas side)

i

Stop valve (liquid side)

Stop valve

Service port

Field piping