Troubleshooting

SiENBE28-901

136

Air Cooled Refrigeration Condensing Unit

[Check 7] Vacuum Drying Procedure

To conduct vacuum drying in the piping system, follow the procedure for <Normal vacuum

drying> shown below.

Furthermore, if moisture can get mixed in the piping system, follow the procedure for <Special

vacuum drying> shown below.

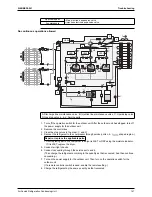

<Normal vacuum drying>

1. Vacuum drying

• Use a vacuum pump that enables vacuuming to a vacuum level of -100.7kPa (5 torr, -755

mmHg).

• Connect a manifold gauge to the service port of the liquid pipe and the gas pipe

respectively, and then run the vacuum pump for a period of two or more hours to achieve

vacuuming to a vacuum level below -100.7kPa.

• If the vacuum level does not reach below -100.7kPa even after vacuuming for a period of

two hours, moisture has got mixed in the system or the system has caused vacuum

leakage. Consequently, conduct vacuuming for a period of another one hour.

• If the vacuum level does not reach below -100.7kPa even after vacuuming for a period of

three hours, conduct leak tests.

2. Leaving in vacuum state

• Leave the piping system in a vacuum state at a level below -100.7kPa for a period of one

or more hours, and then check to be sure that the vacuum gauge reading does not rise. (If

the reading rises, moisture remains in the system or vacuum leaks from the piping.)

3. Additional refrigerant charge

• Purge air from the hose connected to the manifold gauge, and then charge a necessary

amount of refrigerant.

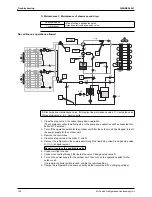

<Special vacuum drying> - In case moisture can get mixed in the piping*:

1. Vacuum drying

• Follow the same procedure as that for normal vacuum drying 1 aforementioned.

2. Vacuum break

• Pressurize to 0.05MPa using nitrogen gas.

3. Vacuum drying

• Conduct vacuum drying for a period of one or more hours. If the vacuum level does not

reach below -100.7kPa even after vacuuming for a period of two hours, repeat Steps 2

Vacuum break and Step 3 Vacuum drying.

4. Leaving in vacuum state

• Leave the piping system in a vacuum state at a level below -100.7kPa for a period of one

or more hours, and then check to be sure that the vacuum gauge reading does not rise.

5. Additional refrigerant charge

• Purge air from the hose connected to the manifold gauge, and then charge a necessary

amount of refrigerant.

*Dew may condense in the piping due to construction during rainy season or a long

construction period or rainwater may enter the piping during construction.