Description of Functions and Operation

SiENBE28-901

50

Air Cooled Refrigeration Condensing Unit

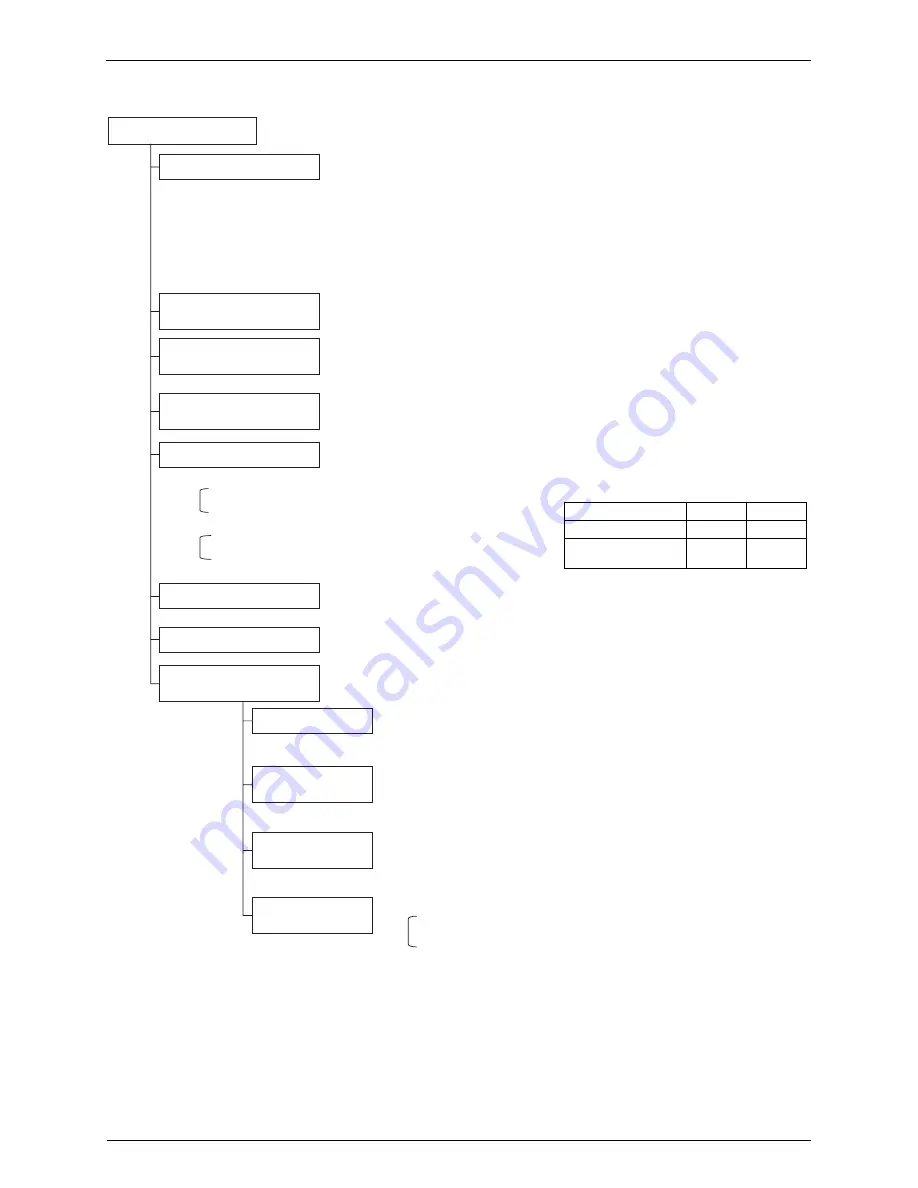

(3) Compressor control

Compressor control

Normal capacity control

High compression ratio

avoidance control

Differential pressure

inversion avoidance control

Oil return control by increasing

the compressor frequency

Control using a reduced LP

Droop control using HP

Droop control using Td

Droop control using

electrical current & INV

Current limit control

Droop control using INV

compressor current

Droop control using INV

compressor fin temperature

STD compressor overcurrent

protection control

• Increase or decrease the compressor frequency using the low pressure as a controlled

variable, in order to achieve the optimum cooling capacity for the target evaporation

temperature (Tst). The target evaporation temperature value used will be the one set by the

dip switches. (For details, see section 2, "Field Settings").

The frequency value will be increased or decreased in steps of 1 every 30 seconds.

• If the low pressure (LP) drops below a pressure equivalent to the target evaporation

temperature (Lpm) –0.015 MPa, the compressor speed will be reduced by one step (every 30

seconds).

• If the low pressure (LP) exceeds a pressure equivalent to the target evaporation temperature

(Lpm) +0.015 MPa, the compressor speed will be increased by one step (every 30 seconds).

However, the thermostat ON/OFF operation will be performed if the load is low.

• If the compression ratio stays above 25 for 10 seconds or more, the compressor speed will be

reduced. (This is intended to protect the compressor scrolls.)

• If the high and low pressure differential is too small, the compressor speed will be increased

according to the actual differential pressure. (This is intended to maintain lubrication.)

• See the "Oil return control" section.

• Reduces the number of compressors being operated or the compressor speed, according to

the actual low pressure and the speed at which the pressure is reduced.

• When stopping the STD compressor:

• Operation mode is not 1, 5 or 7.

• Low pressure (LP) < Rapidly dropping LP

&

• When reducing the INV compressor speed:

• Operation mode = 1

• Low pressure (LP) < LP required for shifting to minimum Hz

&

• Values for rapidly dropping LP and the LP

required for shifting to minimum Hz

LRMEQ**

LRLEQ**

Rapidly dropping LP

0.23MPa

0.02MPa

LP required for shifting

to minimum Hz

0.20MPa

0.02MPa

• The compressor speed is lowered slightly according to the actual high pressure.

High pressure (HP) > 3.23 MPa

• Reduces the compressor speed using the actual discharge thermistor temperature.

The discharge pipe temperature (Td)

≥

115°C for 1 minute or more.

• Control will be performed according to the electrical current setting specified in

Setting Mode 2-2, as the upper limit.

Note that this setting will reduce the cooling capacity.

(For details about setting procedures, see the "Setting Mode 2-2" section)

• Reduces the compressor speed using the inverter actual secondary current.

Inverter secondary current setting for activating droop control: 14.7 A

• Reduces the compressor speed according to the actual inverter fin temperature.

Inverter fin temperature setting for activating droop control: 84°C

• If any of the following conditions is met, the INV. compressor speed will be reduced.

• The STD electrical current value>12.5 A and HP

≥

3.28 MPa for 2 seconds.

• The STD electrical current value>12 A and HP

≥

3.28 MPa for 5 seconds.

or

• If any of the following conditions is met, the STD compressor will be stopped.

• The STD current value>14.95 A for 2.1 seconds.

• The STD current value>13 A for 5 seconds.

• The STD current value>12.35 A for 20 seconds.