14 Charging refrigerant

Installation and operation manual

24

LRYELRNUN5A7Y1

CO

₂

Conveni-Pack outdoor unit and capacity up unit

4P605461-1 – 2020.04

In case of remaining moisture

When the unit is installed on rainy days, moisture may still remain in

the piping after a first vacuum drying is performed. If so, conduct the

following procedure:

1

Pressurize the nitrogen gas up to 0.05 MPa (for vacuum

destruction) and vacuum for at least 2 hours.

2

Afterwards, vacuum dry the unit to –0.1 MPa or less for at least

1 hour.

3

Repeat vacuum destruction and vacuum drying if the pressure

does not reach –0.1 MPa or less.

4

Leave the unit for more than 1 hour with a vacuum pressure of

–0.1 MPa or less. On the vacuum gauge, check if the pressure

does not increase.

13.5

Insulating the refrigerant piping

After finishing the leak test and vacuum drying, the piping must be

insulated. Take into account the following points:

▪ Make sure to insulate the connection piping and refrigerant piping

branching entirely.

▪ Be sure to insulate the liquid and gas piping (for all units).

▪ Use heat resistant polyethylene foam which can withstand a

temperature of 70°C for:

▪ all liquid piping at both the air conditioner and the refrigeration

side.

▪ gas piping at the refrigeration side.

▪ Use heat resistant polyethylene foam which can withstand a

temperature of 120°C for gas piping at the air conditioner side.

Insulation thickness

Take the following into account when determining the insulation

thickness:

Piping

Mode

Minimum

temperature during

operation

Liquid piping

Refrigeration

0°C

Air conditioner

20°C

Gas piping

Refrigeration

–20°C

Air conditioner

0°C

Depending on your local weather conditions, you may need to

increase the thickness of the insulation. If the ambient temperature

exceeds 30°C and the humidity exceeds 80%.

▪ Increase the thickness of the liquid piping with ≥5 mm.

▪ Increase the thickness of the gas piping with ≥20 mm.

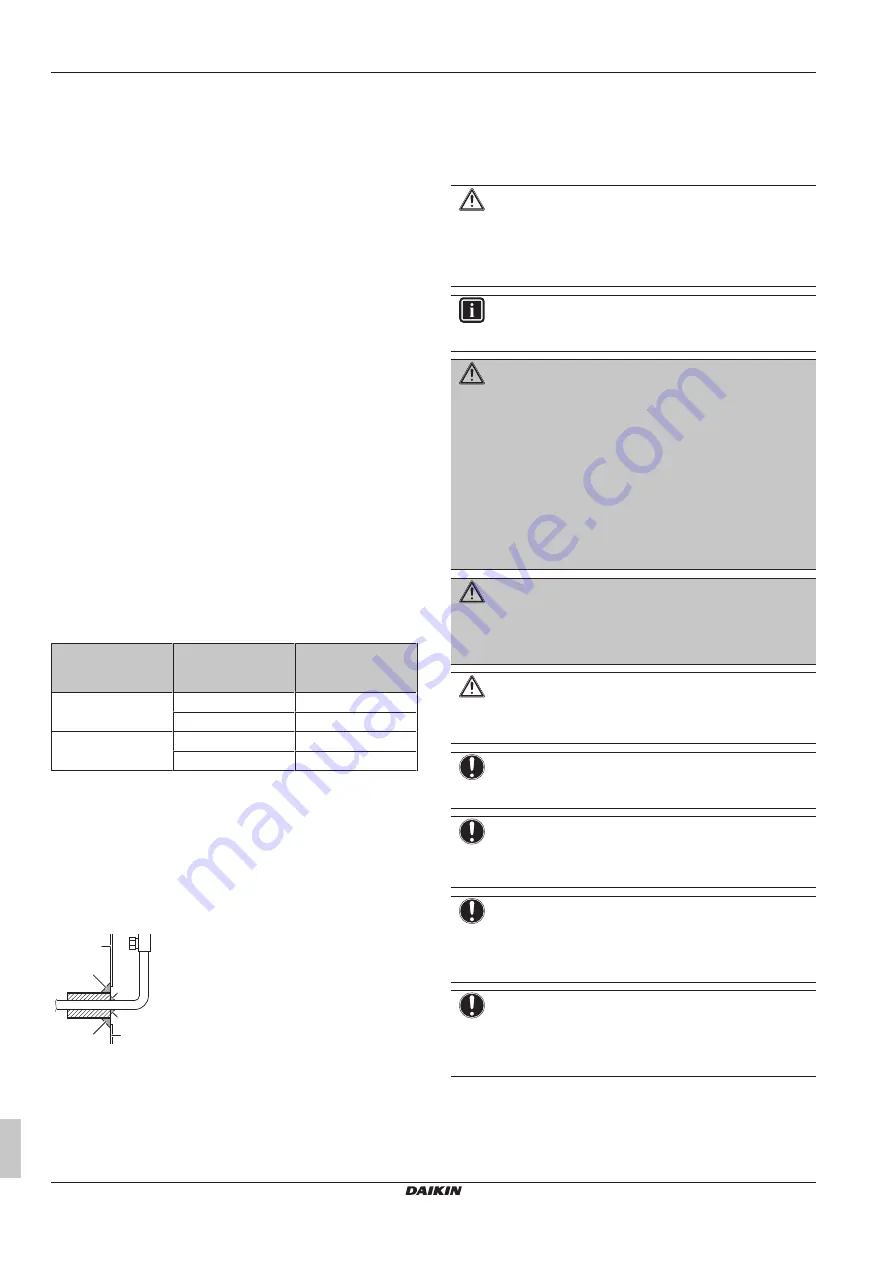

Insulation sealing

To prevent rain and condensed water entering the unit, add a

sealing between the insulation and the front panel of the unit.

a

a

a

a

b

b

a

Sealing material

b

Front panel

14

Charging refrigerant

14.1

Precautions when charging

refrigerant

CAUTION

A vacuumed system will be under triple point. Therefore,

ALWAYS start charging with R744 in vapour state. When

the triple point is reached (5.2 bar absolute pressure or

4.2 bar gauge pressure), you may continue charging with

R744 in liquid state.

INFORMATION

For the operation method of the stop valves, refer to

"13.2 Using stop valves and service ports"

19].

WARNING

▪ Only use R744 (CO

2

) as refrigerant. Other substances

may cause explosions and accidents.

▪ When installing, charging refrigerant, maintaining or

performing service, ALWAYS use personal protective

equipment, such as safety shoes, safety gloves and

safety glasses.

▪ If the unit is installed indoors (for example, in a

machine room), ALWAYS use a portable CO

2

detector.

▪ If the front panel is open, ALWAYS beware of the

rotating fan. The fan will continue rotating for a while,

even after the power switch has been turned off.

WARNING

The unit is already filled with a certain amount of R744. Do

NOT open liquid and gas stop valves until all checks from

the

"17.2 Checklist before commissioning"

35] are

completed.

CAUTION

Do NOT charge liquid refrigerant directly from a gas line.

Liquid compression could cause compressor operation

failure.

NOTICE

If the power of some units is turned off, the charging

procedure cannot be finished properly.

NOTICE

Be sure to turn on the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

NOTICE

Before starting charging procedures, check if the 7‑LEDs

display is as normal (see

34]). If a malfunction code is present, see

"18.1 Solving problems based on error codes"

NOTICE

Close the front panel before any refrigerant charge

operation is executed. Without the front panel attached the

unit cannot judge correctly whether it is operating properly

or not.

Summary of Contents for LRYEN10A7Y1

Page 43: ......