15 Electrical installation

Installation and operation manual

26

LRYELRNUN5A7Y1

CO

₂

Conveni-Pack outdoor unit and capacity up unit

4P605461-1 – 2020.04

3

Calculate the amount of refrigerant for the indoor units using the

Conversion ratio for indoor units: refrigeration

table in this

chapter, based on the type of indoor units and the cooling

capacity.

▪ Calculate the amount of refrigerant for blower coils:

(d)

▪ Calculate the amount of refrigerant for showcases:

(e)

4

Calculate the amount of refrigerant for air conditioner indoor

units using the

Conversion ratio for indoor units: air

conditioners

table in this chapter, based on the model of

indoor units and the number of units connected:

(f)

.

5

Total the amounts of refrigerant for indoor units:

(d)+(e)+(f)=[3]

.

6

Total the calculated amounts of refrigerant and add the required

amount of refrigerant for outdoor unit:

[1]+[2]+[3]+[4]=[5]

.

7

Charge the total amount of refrigerant

[5]

.

8

If a test runs indicates that additional refrigerant is needed,

charge the additional refrigerant and note down its amount:

[7]

.

9

Total the calculated amount of refrigerant

[5]

, the additional

amount of refrigerant during test run

[6]

, and the factory

charged amount of refrigerant

[7]

(see label on the unit). The

total amount of refrigerant in the system is thus:

[5]+[6]+[7]=[8]

.

10

Note down the calculation results in the calculation table.

Calculation table: outdoor unit with capacity up unit

Amount of refrigerant for liquid piping (refrigeration)

Liquid

piping size

Conversion

ratio per

meter of

liquid

piping (kg/

m)

Piping

length (m)

Total

amount of

refrigerant

(kg)

Ø9.5

0.0582

(a1)

Ø12.7

0.1030

(b1)

Ø15.9

0.1603

(c1)

Subtotal (a1)+(b1)+(c1):

[1]

Amount of refrigerant for liquid piping (air conditioner)

Liquid

piping size

Conversion

ratio per

meter of

liquid

piping (kg/

m)

Piping

length (m)

Total

amount of

refrigerant

(kg)

Ø9.5

0.0487

(a2)

Ø12.7

0.0858

(b2)

Ø15.9

0.1333

(c2)

Subtotal (a2)+(b2)+(c2):

[2]

Amount of refrigerant for indoor units

Type of indoor unit

Total

amount of

refrigerant

(kg)

Blower coils

(d)

Showcases

(e)

Air conditioner units

(f)

Subtotal (d)+(e)+(f):

[3]

Required amount of refrigerant for outdoor unit

(kg)

17.0

[4]

Subtotal [1]+[2]+[3]+[4] (kg)

[5]

Factory charged amount of refrigerant into

outdoor unit (kg)

6.3

[6]

Additional amount of refrigerant charged when

test run if required (kg)

(a)

[7]

Total amount of refrigerant [5]+[6]+[7] (kg)

[8]

(a)

The maximum amount of additional refrigerant that can be

charged at the time of the test run is 10% of the amount of

refrigerant as calculated from the capacity of connected indoor

units. Use [7]≤[3]×0.1 to calculate this maximum amount.

Conversion ratio for indoor units: refrigeration

Applicable for outdoor unit with capacity up unit.

Type

Conversion ratio

Blower coil

0.091 kg/kW

Showcase

0.454 kg/kW

Conversion ratio for indoor units: air conditioners

Model

Conversion ratio

FXSN50

0.14 kg/unit

FXSN71

0.22 kg/unit

FXSN112

0.34 kg/unit

14.4

To charge refrigerant

When charging refrigerant into the unit, take the following into

account:

1

Turn ON the power supply of the outdoor unit and all indoor

units (air conditioners, blower coils, showcases).

2

Turn OFF the operation switch of the outdoor unit.

3

Charge refrigerant from the charge port of the stop valve on the

refrigeration liquid side. Keep the stop valve closed.

4

When charging is finished, attach the valve caps to the stop

valve and service port.

Pressure difference too low

If the pressure difference between the charging cylinder and

refrigerant piping is too low, you cannot charge anymore. Continue

as follows to decrease the pressure in the piping and to be able to

continue charging:

1

Open both air conditioner and refrigeration gas stop valves and

air conditioner liquid stop valve.

2

Adjust the opening of the refrigeration liquid stop valve. In case

of long field piping length, the outdoor unit will automatically

stop when charging refrigerant with the liquid stop valve fully

closed.

3

Turn ON the operation switch of the outdoor unit. The pressure

in the refrigerant piping will drop, and charging can be

continued.

4

When the refrigerant is charged, turn OFF the operation switch.

5

Fully open all gas and liquid stop valves.

INFORMATION

After charging, add the total amount of refrigerant to the

name plate on the front panel of the unit.

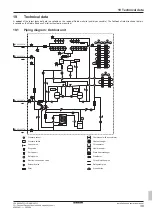

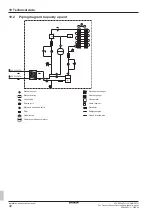

15

Electrical installation

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

NOTICE

The distance between the high voltage and low voltage

cables should be at least 50 mm.

Summary of Contents for LRYEN10A7Y1

Page 43: ......