18 Troubleshooting

Installation and operation manual

37

LRYELRNUN5A7Y1

CO

₂

Conveni-Pack outdoor unit and capacity up unit

4P605461-1 – 2020.04

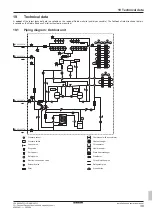

Action

Push button

7-segment display

Push BS3 once, and

indicate each of the

selected parameters.

BS1 BS2 BS3

MODEMODE

MODE

MODE

For example, 7-

segment displays 12

if suction superheat is

12.

Push BS1 once to

return to the initial

state.

BS1 BS2 BS3

MODEMODE

MODE

MODE

Check defrosting

Check if the indoor unit starts defrosting if the defrosting setting is

applied.

CAUTION

ALWAYS turn off the operation switch BEFORE turning off

the power supply.

17.4.2

Correcting after abnormal completion of

the test run

The test operation is only completed if there is no malfunction code

displayed on the user interface or outdoor unit 7‑segment display. In

case of a displayed malfunction code, perform correcting actions as

explained in the malfunction code table. Carry out the test operation

again and confirm that the abnormality is properly corrected.

CAUTION

After the refrigerant is fully charged, do NOT turn off the

operation switch and power supply of the outdoor unit. This

prevents the safety valve actuation due to an increase in

internal pressure under high ambient temperature

conditions.

When internal pressure rises, the outdoor unit can operate

by itself to reduce the internal pressure, even if no indoor

unit is operating.

INFORMATION

Refer to the installation manual of the indoor unit for

detailed malfunction codes related to indoor units.

17.5

Logbook

In accordance with the applicable legislation, the installer must

provide a logbook upon installation of the system. The logbook shall

be updated following any maintenance or repair of the system. In

Europe, EN378 provides the necessary guidance for this logbook.

Content of the logbook

The following information must be provided:

▪ Details of the maintenance and repair works

▪ Quantities and kind of (new, reused, recycled, reclaimed)

refrigerant which have been charged on each occasion

▪ Quantities of refrigerant which have been transferred from the

system on each occasion

▪ Results of any analysis of a reused refrigerant

▪ Source of reused refrigerant

▪ Changes and replacements of components of the system

▪ Results of all periodic routine tests

▪ Significant periods of non-use

Furthermore, you can add:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

Location of the logbook

The logbook shall either be kept in the machinery room, or the data

shall be stored digitally by the operator with a printout in the

machinery room, in which case the information shall be accessible to

the competent person when servicing or testing.

18

Troubleshooting

18.1

Solving problems based on error

codes

If the unit runs into a problem, the user interface displays an error

code. It is important to understand the problem and to take

measures before resetting an error code. This should be done by a

licensed installer or by your local dealer.

This chapter gives you an overview of all possible error codes and

their descriptions as they appear on the user interface.

For detailed troubleshooting of each error, see the service manual.

18.1.1

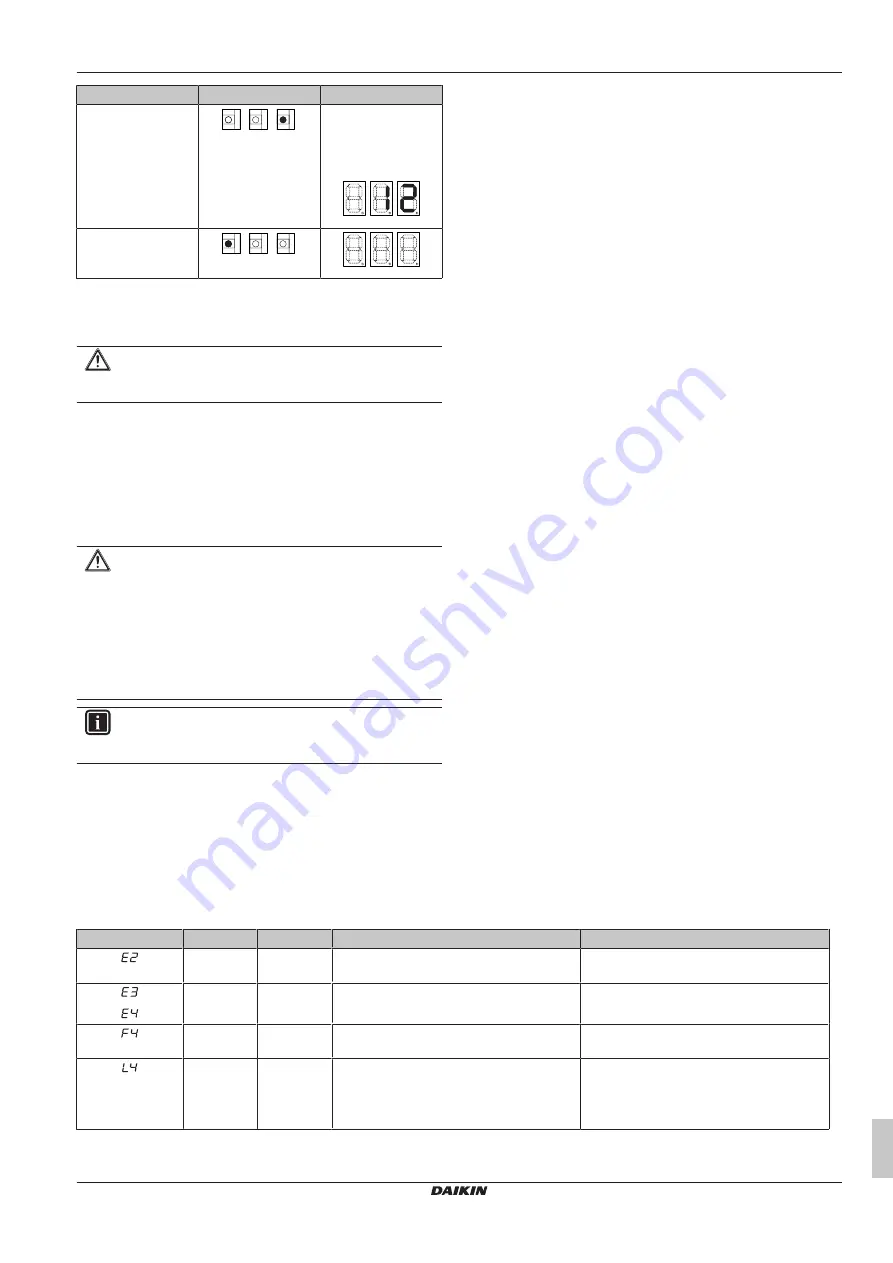

Error codes: Overview

In case other error codes appear, contact your dealer.

Main code

LRYEN10*

LRNUN5*

Cause

Solution

O

O

Electrical leakage

Correct the field wiring and connect ground

wiring.

O

—

The stop valves are closed

Open the stop valve on both the gas and

liquid side.

O

—

Wrong selection of cooling load (including the

expansion valves)

Reselect the cooling load, including the

expansion valve.

O

O

▪ Heat exchanger of outdoor unit is blocked.

▪ The outdoor temperature is above the

maximum operating temperature.

▪ Check if any obstacles block the heat

exchanger and remove them.

▪ Operate

the

unit

only

within

the

temperature operation range.

Summary of Contents for LRYEN10A7Y1

Page 43: ......