4-2

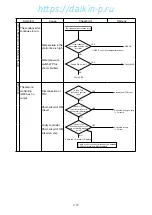

NEXT

PREV

NEXT

PREV

Manual Check

PREV

3/3

2/3

Manual Check

Manual Check

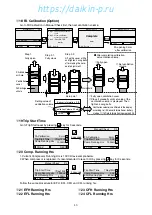

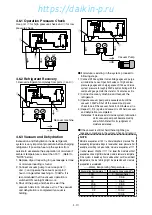

PCC1 ON/OFF

PCC2 ON/OFF

CFH& PCC1 (or 2) ON/OFF

CFL & PCC1 (or 2) ON/OFF

EFH & PCC1 (or 2) ON/OFF

EFL & PCC1 (or 2) ON/OFF

HSV ON/OFF

RSV ON/OFF

LSV ON/OFF

ESV ON/OFF

RM ON/OFF

HuS Reading

All Sensor Calibration

SS Sensor Calibration

RS Sensor Calibration

DSS Sensor Calibration

DRS Sensor Calibration

FA Calibration

Trip Start Time

EFH Running Hrs

EFL Running Hrs

CFH Running Hrs

CFL Running Hrs

0.1

℃

0.2

℃

3mm

7Day12Hr

130Hr

Comp Running Hrs

0.1

℃

0.2

℃

1/3

※

1

※

2

※

3

※

4

※

5

※

6

※

7

※

8

※

9

※

10

※

11

※

12

※

13

※

14

※

15

※

16

※

17

※

18

※

19

※

20

※

21

※

22

※

23

※

24

50Hr

20Hr

40Hr

30Hr

1/3

NEXT

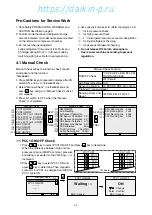

Manual Check

PCC 1 ON/OFF

PCC 2 ON/OFF

---------

--------

PCC 1 ON/OFF

ON

: Change

Enter : Confirm

ESC : Cancel

PCC 1 OFF

PCC 1

PCC 2

CFH

CFL

EFH

PCC 1 ON

PCC 1

PCC 2

CFH

CFL

EFH

I/O board

PCC1 ON/OFF

Waiting ---

ESC : Cancel

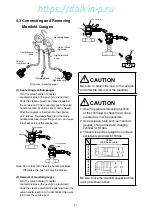

4.1 Manual Check

Manual Check allows the function check of each

component and the function.

<

Access

>

1. Press MENU key at preparation display after I/O

switch ON, and go to "Initialize Menu".

2. Select "Manual Check" in Initialize Menu and

press

key, and go to "Manual Check" consist

of 3 screens.

3. Press I/O switch to OFF when the "Manual

Check" is completed.

Manual Check Function

ON/OFF Check

PCC,CFH,CFL,EFH,EFL,CM

HSV,RSV,LSV,ESV

RM (Circuit)

HuS Sensor Reading HuS

Sensor Calibration

SS,DSS,RS,DRS,FA (option)

Trip Start Time and Reset

Running Hours and

Reset

CM,EFH,EFL,CFH,CFL

※

1 PCC1 ON/OFF Check

1. Press

key to select PCC1 ON/OFF and press

key to determine.

When the difference between high and low

pressure is large (300kPa or more), pressure

equalizing is executed so that "Waiting ---" is

displayed.

2. Press

key to select PCC1 ON and

press

key to determine. Then magnetic

contactor for PCC1 is energized and LED for

PCC1 lights ON.

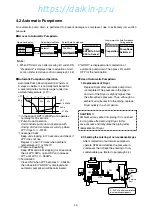

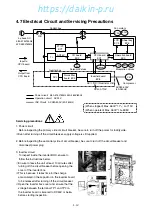

Pre-Cautions for Service Work

1. Note Safety PRECAUTIONS, WARNING and

CAUTION described in page 3.

2. Confirm model name and refrigerant charge

amount indicated on model name plate mounted

on the left wall in compressor chamber.

3. Do not overcharge refrigerant.

Judge refrigerant flow amount if it's Normal or

Shortage during RS

≦

0

℃

in frozen mode by

watching sight glass. Refer to paragraph 4.5.

4. Use correctly 4 service ports (Refer to paragraph 4.5)

①:

for low pressure check

②:

for high pressure check

①

,

④:

for refrigerant recovery, vacuum & dehydration

④:

for liquid refrigerant charging

①:

for gaseous refrigerant charging.

5. Do not release R134a into atmosphere.

Use recover machine according to present

regulation.

04̲01-26̲LX10F11B̲En.indd 4-2

04̲01-26̲LX10F11B̲En.indd 4-2

2014/11/19 16:42:05

2014/11/19 16:42:05

https://daikin-p.ru

Summary of Contents for LX10F11B

Page 2: ...Revision A Correction of spelling 2012 9 28 https daikin p ru...

Page 6: ...https daikin p ru...

Page 82: ...https daikin p ru...

Page 92: ...https daikin p ru...

Page 127: ...5 9 5 6 Sequence https daikin p ru...

Page 128: ...5 10 Stereoscopic wiring diagram https daikin p ru...

Page 129: ...Revision A Correction of spelling 2012 9 28 https daikin p ru...