4-22

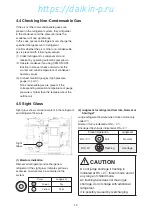

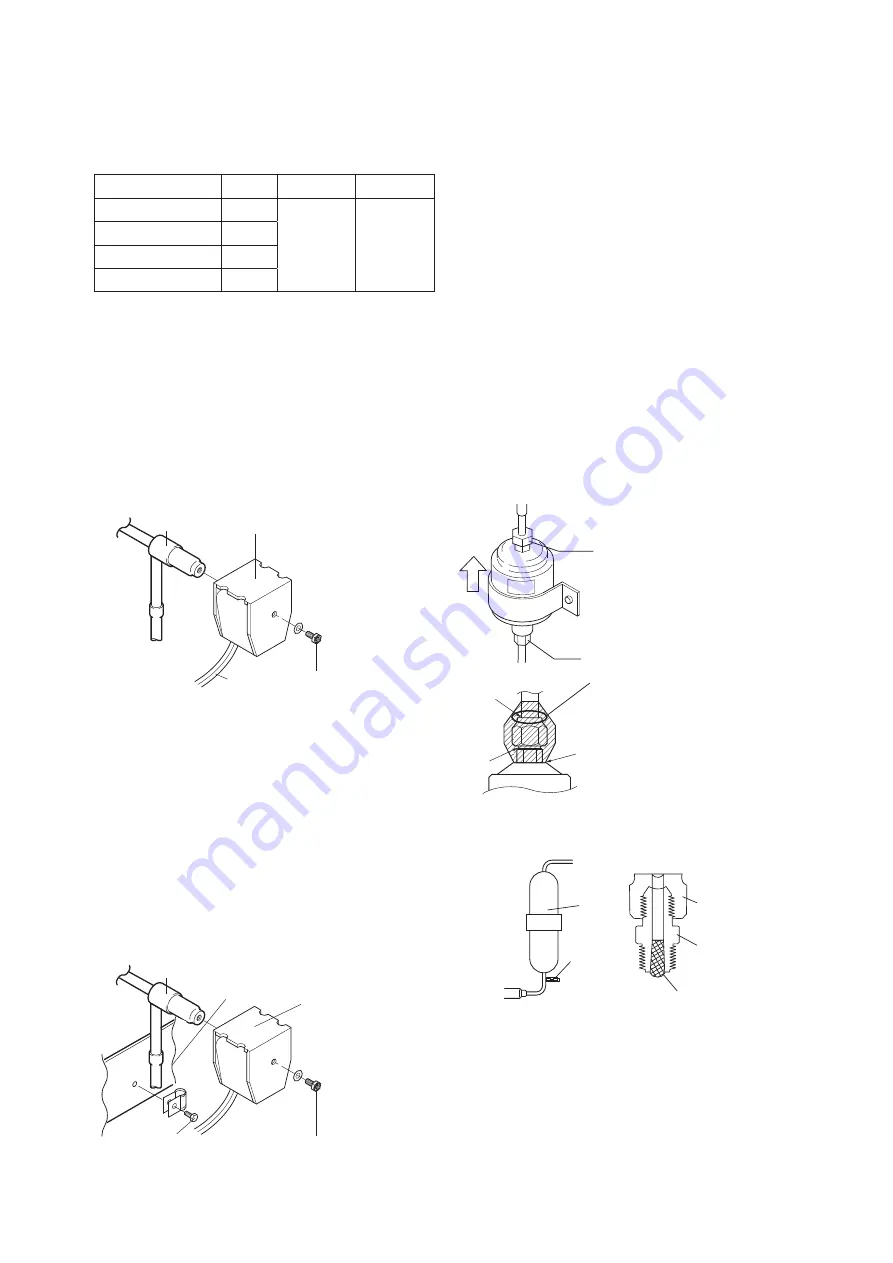

4.8.12 Solenoid Valve

4 Solenoid Valves using in this unit use a common

coil and body.

Name

Symbol

Body

Coil

Liquid solenoid Valve

LSV

VPV-

803DQ

NEV-

MOAB518C

Economizer solenoid Valve ESV

Hot gas solenoid Valve HSV

Reheat coil solenoid Valve

RSV

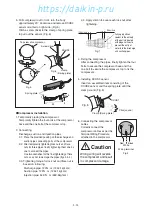

(1) Replacing the coil

①

Remove the lead wire connector from the inside

of the control box, and cut and recover the cable

band.

②

Remove the hexagonal head bolt on the top of

the coil and remove the coil.

③

Replace the coil with a new one and restore

the hexagonal head bolt, the cable band and

connector on the original position.

When reassembling the coil, the tightening

torque should be 1.2 N

・

m (12.2 kg

・

cm).

②

Hexagon head bolt

①

Lead wire

④

Valve body

③

Coil

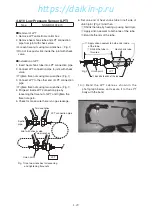

(2) Replacing the valve body

①

Remove the hexagonal head bolt on the top of

the coil remove the coil.

②

Remove the hexagonal head bolt of the mounting

plate, and cut the two pipes at the side of the

valve body.

Disconnect the remaining pipes at the brazed

joint sections.

③

Solder in new valve body while keeping the

temperature of the valve body below 120

℃

(248 F) by cooling.

④

Install the coil and the hexagonal head bolt of

the mounting plate and the connector into their

original position.

⑤

Hexagon head bolt for fixing plate

①

Hexagon head bolt

②

Coil

③

Valve body

④

mounting plate

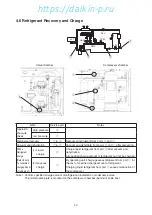

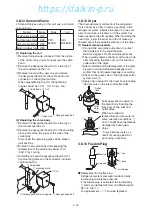

4.8.13 Dryer

The dryer absorbs moisture from the refrigerant.

It also works as a filter to remove particles in the

refrigerant system. Replace the dryer if it does not

absorb moisture, is blocked, or if the system has

been opened to the atmosphere. When installing the

new dryer, follow the arrow and do not make any

mistake about the installation direction of the dryer.

(1) Replacement procedure

①

Conduct the automatic pumpdown to collect

the refrigerant in the liquid receiver.

Refer to paragraph 4.2 for the automatic pumpdown.

②

Then, quickly replace the dryer with a new one

after loosening the flare nuts on the inlet and

outlet side of the dryer.

③

After completing of the replacement of the dryer,

be sure to conduct refrigerant leakage test to

confirm that no refrigerant leakage is occurring.

④

Check on the green color of the sight glass after

system start up.

⑤

Apply silicon sealant to the dryer body including

the flare nuts on the inlet and outlet sides.

Outlet

flare

nut

Inlet

flare

nut

Fully apply silicon sealant to

the dryer body including the

flare nuts on the inlet and

outlet sides.

When put under low

temperature and pressure by

some operation conditions,

①

and

②

might have the threads

damaged by frozen dew

drops.

③

may become rusty as a

result of coating peel-off at

work using a spanner.

①

②

③

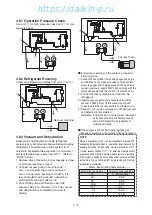

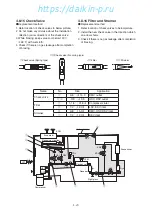

4.8.14 Fusible Plug

Receiver

Fusible plug

①

Cap

②

Body

③

Fusible plug

●

Replacement of fusible plug

Refrigerant system pressure rise abnormally

fusible plug will release pressure.

If the fusible plug is activated, the fusible alloy

③

melts and refrigerant blow out (Melting point:

95

℃

to 100

℃

).

For replacement,

①

-

③

shall be replaced.

04章̲LX10F11B3̲TR16-02̲En.indd 4-22

04章̲LX10F11B3̲TR16-02̲En.indd 4-22

2016/02/03 16:22:14

2016/02/03 16:22:14

https://daikin-p.ru

Summary of Contents for LX10F11B3

Page 7: ...https daikin p ru ...

Page 83: ...https daikin p ru ...

Page 93: ...https daikin p ru ...

Page 121: ...https daikin p ru ...

Page 129: ...https daikin p ru ...

Page 138: ...6 9 6 6 Sequence AIR WATER COOLED AIR WATER COOLED https daikin p ru ...

Page 139: ...6 10 Stereoscopic wiring diagram AIR WATER COOLED https daikin p ru ...