1-16

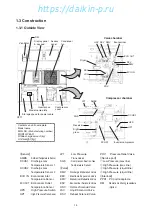

1.4.6 Common Control

●

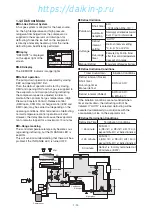

Compressor running control

Compressor changes speed Min. 20 rps to Max.

130 rps with inverter control.

①

Start up control

③

Pull down control

⑤

Modulation

Compressor

Time

Max.

130 rps

Min.

20 rps

②

Step up control

④

Step down control

Cooling OFF

SP

RS or SS

Unit ON

Approx.

67 rps

①

Start up control

After unit switch ON, unit goes to calibration valves

at first and compressor start up control. Start up

control is to protect liquid back condition due to unit

stops for long time under low ambient temperature.

It is controlled with three steps: (1) pump down

operation, (2) operation not in wet conditions 1,

(3) operation not in wet conditions 2. Although it

normally completes in several minutes, sometimes

it takes almost 20 minutes if totalizing the time of

guard timer at each step.

②

Step up control

After completion of start-up control, the rotation

speed will increase to the maximum speed of the

pull down operation by having a few steps. It takes

approximately two minutes.

③

Pull down control

It runs at the maximum rotation speed (130 rps)

during pull down. When some cause makes the

protection control activated, the rotation speed may

decrease, giving a high priority on the protection control.

④

Step down control

When the control temperature RS (frozen) or SS

(chilled) reaches the setpoint temperature SP, the

rotation speed of the compressor will be slowed

down gradually. It takes two to three minutes.

⑤

Modulation

When the control temperature RS or SS reaches SP,

the modulated control starts, and the compressor

controls rotation speed in response to temperature

difference between RS (or SS) and SP. (at the

speed of as low as 20 rps)

The compressor stops at small heat load condition.

●

Calibration valves

Turning the unit switch into ON triggers initial

operation for calibrating valves EEV, EMV, and DMV.

EEV and EMV are fully opened (420pls) then fully

closed (0pls). DMV is fully opened (760pls), then

fully closed (0pls) and fully opened (760pls) again.

The change of valve opening can be checked on

the LCD screen. Operate keys immediately when

the operation screen is displayed. The operation of

the modulation valve coils can be checked during

maintenance. (Refer to

※

3 Sensor information in

paragraph 2.3.)

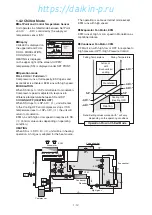

●

Compressor protection control

When an operating status phenomenon is

detected, rotation speed of the compressor will

gradually slow down to protect the compressor. It

will resume to normal operation when the operation

status returns to normal. Three examples follow.

1. Suppression control of high-pressure increase

starts at HPT

≧

2110kPa.

2. Suppression control of low-pressure decrease

starts at LPT

≦

-50kPa.

3. Suppression control of discharged-gas-

temperature increase starts at DCHS

≧

117

℃

.

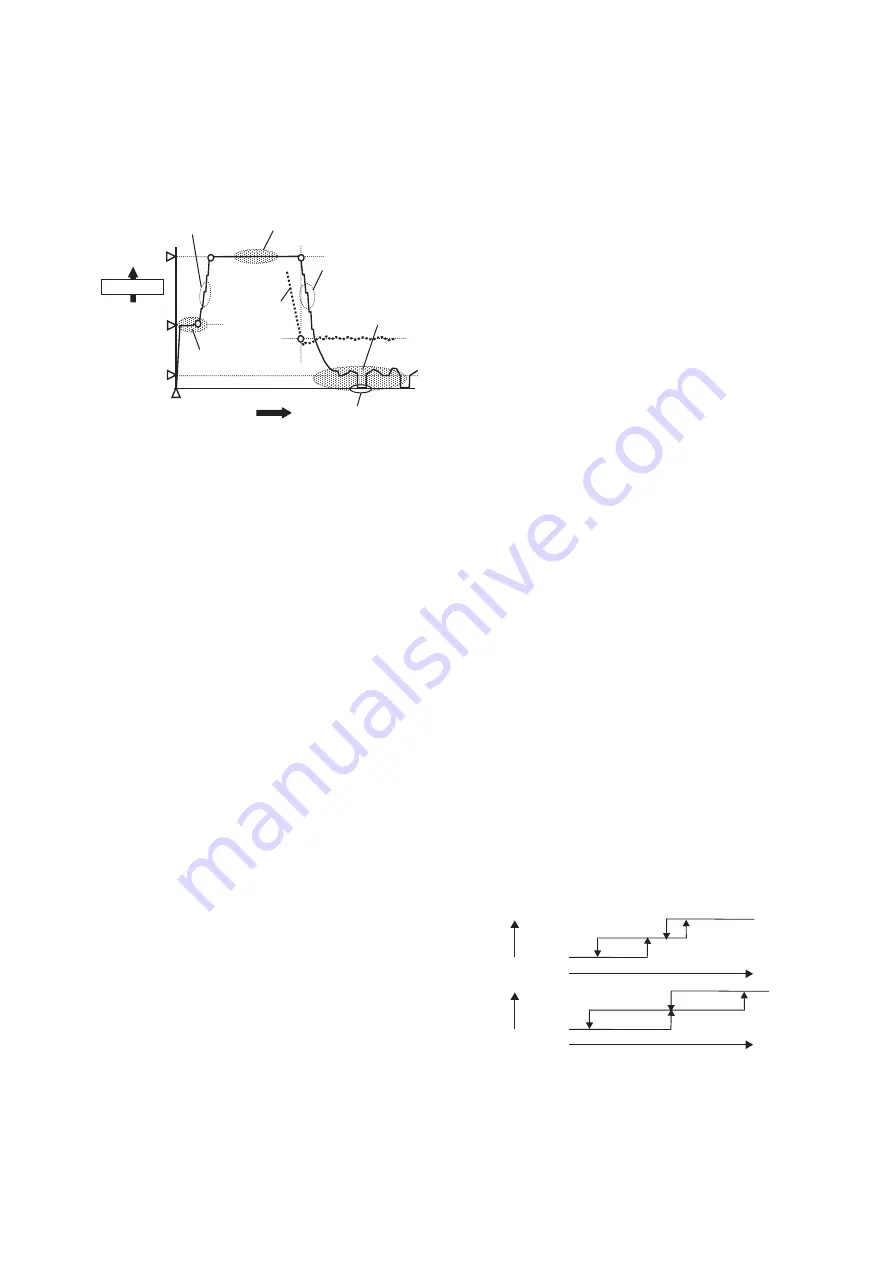

●

High pressure control

When ambient temperature is low, the high pressure

will decrease. Accordingly, the low pressure will

decrease too. In order to prevent this situation,

optimum pressure is maintained by switching the

condenser fan between OFF

⇔

Low speed

⇔

High

speed based on the high pressure value.

High Speed

Low Speed

OFF

HPT<800kPa

HPT>800kPa

HPT>1000kPa

HPT<600kPa

<

In operation

>

<

Startup

>

High Speed

Low Speed

OFF

HPT<500kPa

HPT>400kPa

HPT>600kPa

HPT<300kPa

Pressure

Pressure

Speed

Speed

*

The control values described above may vary

depending on operation status.

*

CFM stops for ten seconds when switching from

high speed to low speed.

01章̲LX10F11B3̲TR16-02̲En.indd 1-16

01章̲LX10F11B3̲TR16-02̲En.indd 1-16

2016/02/02 9:09:36

2016/02/02 9:09:36

https://daikin-p.ru

Summary of Contents for LX10F11B3

Page 7: ...https daikin p ru ...

Page 83: ...https daikin p ru ...

Page 93: ...https daikin p ru ...

Page 121: ...https daikin p ru ...

Page 129: ...https daikin p ru ...

Page 138: ...6 9 6 6 Sequence AIR WATER COOLED AIR WATER COOLED https daikin p ru ...

Page 139: ...6 10 Stereoscopic wiring diagram AIR WATER COOLED https daikin p ru ...