2

Contents

SAFETY PRECAUTIONS

DANGER

………………………………………………

4

WARNING

………………………………………………

4

CAUTION

………………………………………………

4

Chapter 1 Unit Specifications

……………………

1-1

1.1 Operation Range and Main Specifications

…

1-2

1.1.1 Operation Range

…………………………

1-2

1.1.2 Main Specifications

………………………

1-2

1.2 Protection Device and Setting Value

…………

1-3

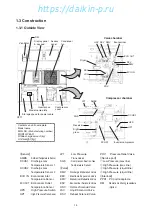

1.3 Construction

……………………………………

1-4

1.3.1 Outside View

………………………………

1-4

1.3.2 Inside View

…………………………………

1-5

1.3.3 Control Box

…………………………………

1-6

1.3.4 CPU Board and I/O Board

………………

1-7

1.3.5 Inverter Box

………………………………

1-8

1.3.6 Valves and Functions

……………………

1-9

1.3.7 Sensor Location

……………………………

1-9

1.3.8 Printed Circuit Board

……………………

1-10

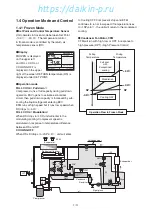

1.4 Operation Mode and Control

………………

1-11

1.4.1 Frozen Mode

……………………………

1-11

1.4.2 Chilled Mode

……………………………

1-12

1.4.3 Dehumidification Mode (Option)

………

1-13

1.4.4 Defrost Mode

……………………………

1-14

1.4.5 Compressor, Fan Motor, Valve Function

…

1-15

1.4.6 Common Control

………………………

1-16

1.5 Optional Functions

…………………………

1-17

1.5.1 ASC, Automatic Setpoint Change

……

1-17

1.5.2 Cold Treatment Transport

……………

1-18

1.5.3 ACT, Automatic Cold Treatment

………

1-18

1.5.4 Ventilator Volume Detection (FA Sensor)

…

1-19

1.5.5 Remote Monitoring Receptacle

………

1-19

1.6 Battery Mode

…………………………………

1-19

1.7 Information Interchange with Personal Computer

…

1-20

Chapter 2 Controller

………………………………

2-1

2.1 Operation Panel

…………………………………

2-2

2.2 Controller Functions List

………………………

2-3

2.3 Operation Procedure

…………………………

2-4

2.4 Wake-up Battery (Rechargeable Battery)

…

2-18

2.5 Alarm Code

…………………………………

2-19

2.6 Alarm Diagnosis

……………………………

2-22

2.7 General Diagnosis

……………………………

2-45

Chapter 3 PTI & Periodic Inspection

……………

3-1

3.1 Pre-Trip Inspection

……………………………

3-2

3.2 Manual Inspection

………………………………

3-3

3.3 Automatic PTI

…………………………………

3-5

3.3.1 Automatic PTI Step No. and Contents

…

3-6

3.3.2 Automatic PTI Alarm

………………………

3-6

3.4 Periodic Inspection

……………………………

3-8

Chapter 4 Service

…………………………………

4-1

4.1 Manual Check

…………………………………

4-2

4.2 Automatic Pumpdown

…………………………

4-6

4.3 Connecting and Removing Manifold gauges

…

4-7

4.4 Checking Non-Condensable Gas

……………

4-8

4.5 Sight Glass

………………………………………

4-8

4.6 Refrigerant Recovery and Charge

……………

4-9

4.6.1 Operation Pressure Check

……………

4-10

4.6.2 Refrigerant Recovery

…………………

4-10

4.6.3 Vacuum and Dehydration

………………

4-10

4.6.4 Refrigerant Charge

……………………

4-11

4.7 Electrical Circuit and Servicing Precautions

…

4-12

4.8 Parts Replacement

…………………………

4-13

4.8.1 Compressor

……………………………

4-13

4.8.2 Evaporator Fan and Fan Motor Removing

…

4-15

4.8.3 Inverter Board (EC8)

……………………

4-16

4.8.4 CPU Board (EC1)

………………………

4-16

4.8.5 I/O Board (EC2)

…………………………

4-17

4.8.6 Operation Board (EC3)

…………………

4-17

4.8.7 PT/CT Board (EC7)

……………………

4-17

4.8.8 High Pressure Switch (HPS)

…………

4-18

4.8.9 High Pressure Sensor (HPT)

…………

4-18

4.8.10 Low Pressure Sensor (LPT)

…………

4-19

4.8.11 Electronic Expansion Valve (EEV), Economizer Modulation

Valve (EMV), Discharge Modulation Valve (DMV)

…

4-20

4.8.12 Solenoid Valve

…………………………

4-21

4.8.13 Dryer

……………………………………

4-21

4.8.14 Fusible Plug

……………………………

4-21

4.8.15 Check Valve

……………………………

4-22

4.8.16 Filter and Strainer

……………………

4-22

4.9 Emergency Operation at Controller Malfunction

…

4-23

4.9.1 Wiring Change of Controller

……………

4-23

4.9.2 Fixing of EEV Opening

…………………

4-24

4.9.3 Fixing of EMV Opening

…………………

4-24

4.9.4 Fixing of DMV Opening

…………………

4-25

00前付̲LX10F11B3̲TR16-02̲En.indd 2

00前付̲LX10F11B3̲TR16-02̲En.indd 2

2016/02/01 17:28:33

2016/02/01 17:28:33

https://daikin-p.ru

Summary of Contents for LX10F11B3

Page 7: ...https daikin p ru ...

Page 83: ...https daikin p ru ...

Page 93: ...https daikin p ru ...

Page 121: ...https daikin p ru ...

Page 129: ...https daikin p ru ...

Page 138: ...6 9 6 6 Sequence AIR WATER COOLED AIR WATER COOLED https daikin p ru ...

Page 139: ...6 10 Stereoscopic wiring diagram AIR WATER COOLED https daikin p ru ...