4

SAFETY

PRECAUTIONS

Always observe the following points

before operating or inspecting a unit

DANGER

Always shut off the main power supply

of the facility before disconnecting the

power plug.

Always turn off the main power supply of

the facility before inspecting the interior

of the control box.

To inspect inside the inverter box,

ensure to follow the instructions below.

1) Ensure to leave the unit at least 10 minutes

after turning off the circuit breaker before

opening the cover of the inverter box.

* This is because it takes time for the charge

accumulated in the capacitor on the inverter board

to be released.

2) Open the inverter box cover and ensure that

the voltage between the terminal TP1 and TP2

on the inverter board is less than DC50V before

starting inspection.

R134a should be used as refrigerant.

Be sure to prevent air from becoming mixed in with

refrigerant, and never charge the equipment used for

hydrostatic pressure tests with gas that contains air

or O

2

.

If any other refrigerant not specified is charged, or

charging procedure is not correct, it may explosions

may occur.

WARNING

Do not touch the condenser fan while

power to the unit is ON.

Before removing the condenser fan cover, turn off

the circuit breaker and disconnect the power plug.

During air-cooled operation and water-cooled

operation : Condenser fan may start and stop

automatically for the refrigerant high pressure

control.

CLASS 1 PRODUCT SPECIFIED BY THE

FLUOROCARBONS EMISSION

CONTROL LAW

HFC

IS USED FOR THIS PRODUCT AS A

REFRIGERANT.

(1) Emission of fluorocarbons into the atmosphere

without permission is prohibited.

(2) Recovery of fluorocarbons is mandatory when

scrapping and servicing this product.

(3) The kind of fluorocarbon and its amount are

stated in the manufacturer's label.

The replacement of the electric wiring must be

performed by the manufacturer, distributor, or a

certified electrician.

CAUTION

Wash the refrigeration unit with fresh water at PTI.

1. Carefully flush the external condenser with fresh

water to remove the salt that sticks to it.

2. Corrosive gases generated from the cargo may

corrode the copper pipes and aluminum fin of the

internal evaporator. Therefore, wrap up the cargo

properly to prevent such corrosion.

Major corrosive gases include chlorine, ammonia,

sulfuric acid, acetic acid, sulfur dioxide etc.

Securely close the control box cover.

Otherwise, it will allow water entry.

Use only Daikin specified refrigerant oil

(IDEMITSU, Daphne Hermetic Oil FVC68D).

Open the oil bottle, just before charging the oil.

Do not leave the bottle open for a long time to

avoid moisture entry.

Using refrigerant oil which has absorbed moisture

may cause problems with the unit.

Do not release refrigerant R134a into

atmosphere. Use recovery machine according to

present regulation.

00前付̲LX10F11B3̲TR16-02̲En.indd 4

00前付̲LX10F11B3̲TR16-02̲En.indd 4

2016/02/01 17:28:34

2016/02/01 17:28:34

https://daikin-p.ru

Summary of Contents for LX10F11B3

Page 7: ...https daikin p ru ...

Page 83: ...https daikin p ru ...

Page 93: ...https daikin p ru ...

Page 121: ...https daikin p ru ...

Page 129: ...https daikin p ru ...

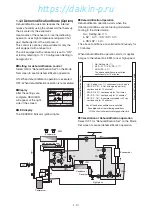

Page 138: ...6 9 6 6 Sequence AIR WATER COOLED AIR WATER COOLED https daikin p ru ...

Page 139: ...6 10 Stereoscopic wiring diagram AIR WATER COOLED https daikin p ru ...