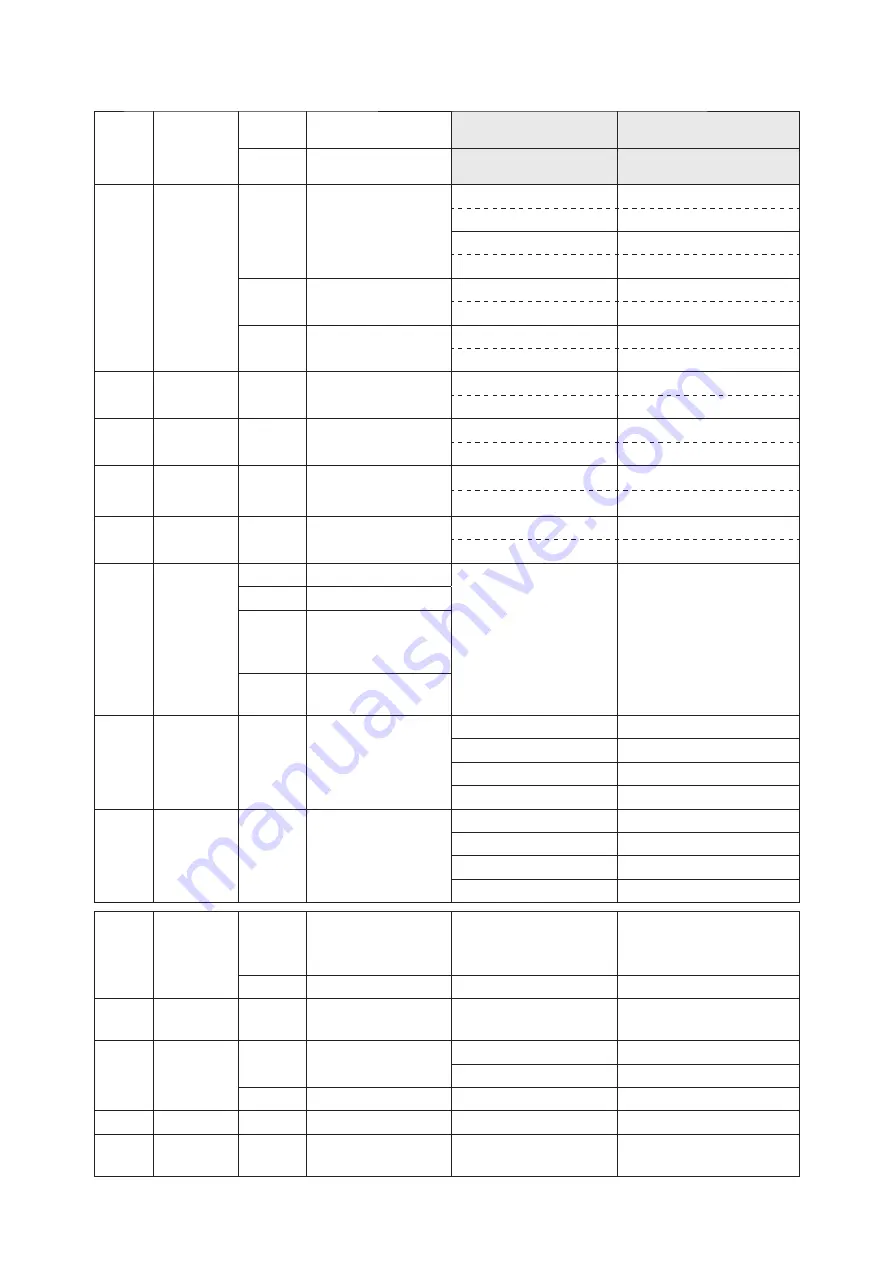

3-7

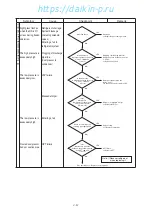

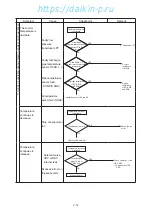

P08

INV

check

T081

The frequency does not

match to command frequency.

T082

No pressure difference

between high and low pressure.

P10

EMV, ESV

check

T101

EMV or ESV failure

EMV wiring failure

Check EMV coil and wiring.

EMV coil burning out

Check EMV outlet pipe temperature.

ESV coil failure

Check ESV coil and wiring.

ESV valve body failure Check ESV outlet pipe temperature.

T102

ESV failure

ESV wiring failure

Check ESV coil and wiring.

ESV coil burning out

Check clicking sound from ESV.

T103

EMV failure

EMV wiring failure

Check EMV coil and wiring.

EMV coil burning out

Check EMV outlet pipe temperature.

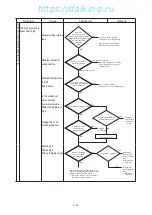

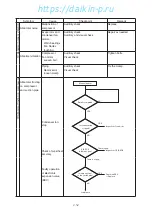

P12

LSV

check

T121

LSV does not operate.

LSV coil failure

Check LSV coil and wiring.

LSV valve body failure

Check LSV outlet pipe temperature.

P14

HSV

check

T141

HSV does not open.

HSV coil failure

Check HSV coil and wiring

HSV valve body failure Check HSV outlet pipe temperature.

P16

RSV

check

T161

RSV does not open.

RSV coil failure

Check RSV coil and wiring.

RSV valve body failure Check RSV outlet pipe temperature.

P18

DMV

check

T181

DMV does not operate.

DMV wiring failure

Check DMV coil and wiring.

DMV coil burning out

Check clicking sound from DMV.

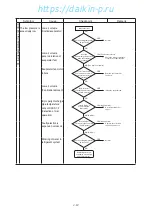

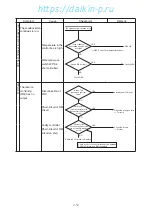

P20

HPS

check

T201

OFF value is low.

①

HPS failure

②

HPT failure

③

Gas leakage from

manifold gauges

①

Check HPT.

②

Compare to manifold

gauges.

③

Remove manifold

gauges.

T202

Does not reset

T203

HPS: High pressure

does not rise.

HPS does not operate.

T204

HPS: High pressure

does not drop.

P22

Pump down

check

T221

Pump down time is

too long.

EEV failure

Check EEV coil, wiring, valve body.

Leakage through HSV

Check HSV outlet pipe temperature.

Leakage through RSV

Check RSV outlet pipe temperature.

Leakage through ESV

Check ESV outlet pipe temperature.

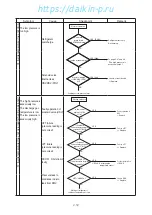

P24

Valve leak

check

T241

Solenoid valve

internal leakage

Leakage through HSV

Check HSV outlet pipe temperature.

Leakage through RSV

Check RSV outlet pipe temperature.

Leakage through ESV

Check ESV outlet pipe temperature.

Leakage through EEV

Check EEV outlet pipe temperature.

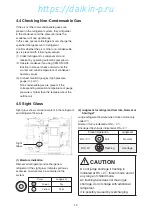

P50

0

℃

pull-down

T501

Ambient temperature

is out of condition.

(Unit is normal.)

Ambient temperature is

below -10

℃

and above

43

℃

Check ambient temperature

T502

Pull-down time is too long.

P60

0

℃

maintenance

No alarm No judgment

P70

Defrost test

T701

Defrost initiation

conditions out of range

EOS failure

Check EOS.

HSV internal leakage

Check HSV outlet pipe temperature.

T702

Defrost time is too long. EOS failure

Check EOS.

P80

-18

℃

pull-down

T801

Pull-down time is too long.

P90

-18

℃

maintenance

No alarm

03章̲LX10F11B3̲TR16-02̲En.indd 3-7

03章̲LX10F11B3̲TR16-02̲En.indd 3-7

2015/12/21 15:43:11

2015/12/21 15:43:11

https://daikin-p.ru

Summary of Contents for LX10F11B3

Page 7: ...https daikin p ru ...

Page 83: ...https daikin p ru ...

Page 93: ...https daikin p ru ...

Page 121: ...https daikin p ru ...

Page 129: ...https daikin p ru ...

Page 138: ...6 9 6 6 Sequence AIR WATER COOLED AIR WATER COOLED https daikin p ru ...

Page 139: ...6 10 Stereoscopic wiring diagram AIR WATER COOLED https daikin p ru ...