36

目 次

3.10

チャートレス機能

…………………………

3-57

3.10.1

チャート表示機能

……………………

3-57

3.10.2 P

コード

(プルダウンタイム表示)

……

3-59

3.10.3

チャートレスコード

…………………

3-60

3.10.3.1

チャートレスコード一覧

………

3-60

3.10.3.2

Hコード

…………………………

3-61

3.10.3.3

dコード

……………………………

3-63

3.11

通信モデム

…………………………………

3-64

4.

サービスとメンテナンス

…………………………

4-1

4.1

サービスの方法

………………………………

4-1

4.1.1

冷媒の回収

………………………………

4-1

4.1.2

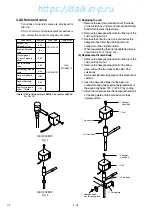

ゲージマニホールドの取付け、取外し

…

4-1

4.1.3

自動ポンプダウン

………………………

4-3

4.1.4

冷媒の回収および充填

…………………

4-5

4.2

主要機器とメンテナンス

……………………

4-9

4.2.1

スクロール圧縮機

………………………

4-9

4.2.2

ファンおよび電動機

……………………

4-15

4.2.3 PT/CT

ボード

(

EC9756

)

………………

4-16

4.2.4

電子膨張弁

………………………………

4-17

4.2.5

温度式膨張弁(

TEV

)

…………………

4-18

4.2.6

吸入比例弁

………………………………

4-19

4.2.7

ドライヤ

…………………………………

4-20

4.2.8

電磁弁

……………………………………

4-21

4.2.9

吐出圧力調整弁

…………………………

4-22

4.2.10

逆止弁

…………………………………

4-22

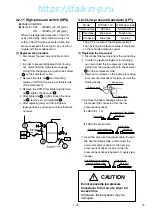

4.2.11

高圧圧力開閉器(

HPS

)

………………

4-23

4.2.12

低圧圧力センサ(

LPT

)

………………

4-23

4.2.13

高圧圧力センサ(

HPT

)

………………

4-24

4.2.14

水用圧力開閉器(

WPS

)

……………

4-24

4.2.15

湿度センサー

…………………………

4-24

4.2.16

換気口開度検知器(FAセンサー)

…

4-25

4.2.17

空冷凝縮器、蒸発器

…………………

4-25

4.2.18

水冷凝縮器

……………………………

4-26

4.2.19

可溶栓

…………………………………

4-26

4.2.20

リキッド/モイスチャーインジケータ

…

4-26

4.2.21

真空乾燥

………………………………

4-27

5.

附属機器

……………………………………………

5-1

5.1 USDA

低温処理輸送

…………………………

5-2

5.1.1 USDA

センサー、レセプタクルの型式

…

5-3

5.1.2

初期設定

…………………………………

5-3

5.1.3 USDA

センサーキャリブレーション

……

5-3

5.1.4 USDA

低温処理輸送要件

…………………

5-3

5.1.5 USDA

レポート

……………………………

5-3

6.

故障診断

……………………………………………

6-1

6.1

冷媒システム・電気システム

………………

6-1

6.2

電子式コントローラ

…………………………

6-5

6.3

自動

PTI

のトラブルシューティング

(

J

コード)

…

6-10

6.4

緊急運転の方法

………………………………

6-12

6.4.1

コントローラの緊急運転

………………

6-12

6.4.2

コントローラの短絡運転

………………

6-13

6.4.3

電子膨張弁の緊急運転

…………………

6-14

6.4.4

吸入比例弁の緊急運転方法

……………

6-15

6.4.5

吹出センサ・吸込センサ緊急運転

……

6-16

7.

付図

…………………………………………………

7-1

7.1

ボルトの標準締付トルク

……………………

7-1

7.2

フレヤナットの標準締付トルク

……………

7-1

7.3

閉鎖弁の標準締付トルク

……………………

7-1

7.4

モータコイル及び電磁弁コイルの抵抗値

……

7-2

7.5

電子膨張弁コイルの標準締付トルク(

EV

コイル)

…

7-2

7.6 HFC134a

、温度一蒸気圧特性表

……………

7-3

7.7

温度換算表と温度センサ

(

SS/RS/DSS/DRS/RSS/RRS/EIS/EOS/SGS

/AMBS

)特性表

………………………………

7-4

7.8

温度換算表と温度センサ(

DCHS

)特性表

……

7-5

7.9

高圧圧力センサ特性表

………………………

7-5

7.10

低圧圧力センサ特性表

………………………

7-5

7.11

圧力換算表

……………………………………

7-6

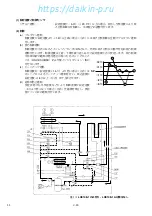

7.12

配管系統図

……………………………………

7-7

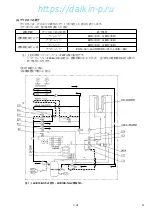

7.13

電気配線

………………………………………

7-8

7.14

ヒューズ保護対象表

…………………………

7-9

7.15

シーケンス

…………………………………

7-10

7.16

実体配線図

…………………………………

7-11

取扱上の注意

・危険

…………………………………………………

3

・警告

…………………………………………………

4

・注意

…………………………………………………

5

1.

概要

…………………………………………………

1-1

1.1

運転範囲

………………………………………

1-1

1.2

各部の名称

……………………………………

1-1

1.3

運転操作

………………………………………

1-2

1.3.1

運転準備

…………………………………

1-2

1.3.2

運転準備と操作

…………………………

1-3

1.3.3

運転中の点検

……………………………

1-4

1.3.4

停止後の処置

……………………………

1-4

1.3.5

ベンチレータの開閉

……………………

1-5

2.

製品データ

…………………………………………

2-1

2.1

主仕様

…………………………………………

2-1

2.2

部品名称

………………………………………

2-2

2.2.1

庫外側

……………………………………

2-2

2.2.2

庫内側

……………………………………

2-4

2.2.3

コントロールボックス

…………………

2-6

2.3

機能部品・保護装置の設定値

………………

2-9

2.4

運転圧力と電流値

……………………………

2-10

2.5

運転モードと制御

……………………………

2-14

2.5.1

フローズン運転

…………………………

2-15

2.5.2

チルド運転

………………………………

2-17

2.5.3

デフロスト運転

…………………………

2-19

2.5.4

除湿制御運転

……………………………

2-22

2.5.5

共通制御

…………………………………

2-23

3.

電子式コントローラ

………………………………

3-1

3.1

機能

……………………………………………

3-1

3.2

電子式コントローラの基本操作

……………

3-3

3.2.1

コントロールパネル

……………………

3-3

3.2.2

設定温度と運転モード

…………………

3-5

3.3

操作方法

………………………………………

3-6

3.3.1

操作方法フローチャート

………………

3-6

3.3.2

各表示モード操作方法

…………………

3-9

1.

カレント

(運転状態)

表示モード

…………

3-9

2.

運転設定モード

…………………………

3-10

3.

電池モード

………………………………

3-11

4.

モード運転

………………………………

3-12

5.

表示

(

LED

部)

消灯モード

…………………

3-15

6.

センサ表示モード

………………………

3-16

7.

温度記録スクロールモード

……………

3-19

8.

アラーム記録スクロールモード

………

3-22

3.3.3

設定フローチャート

……………………

3-24

10.

オプション機能設定モード

……………

3-26

11.

基本機能設定モード

……………………

3-27

12.

オプション条件機能設定モード

………

3-29

13.

インプットデータモード

………………

3-31

14.

コントローラソフトダウンロードモード

…

3-32

3.4

アラーム表示とバックアップ機能

…………

3-33

3.4.1

アラーム一覧表

…………………………

3-33

3.4.2

センサ異常時のバックアップ運転

……

3-34

3.5

電池

……………………………………………

3-36

3.5.1

仕様

………………………………………

3-36

3.5.2

機能

………………………………………

3-36

3.5.3

バッテリーチェック

……………………

3-36

3.5.4

バッテリー交換

(充電電池)

……………

3-37

3.6

パソコンとの情報交換

………………………

3-38

3.6.1

データロギング

…………………………

3-39

3.6.2

パソコンソフトの構成

…………………

3-40

3.7

コントローラの点検方法

……………………

3-42

3.8

コントローラの交換および初期設定

………

3-43

3.8.1

コントローラの交換

……………………

3-43

3.8.2

イニシャル設定&操作要領

……………

3-44

3.9 PTI

(使用前点検)

と定期点検

………………

3-45

3.9.1

点検項目

…………………………………

3-46

3.9.2

自動

PTI

…………………………………

3-49

3.9.2.1 PTI

選択モード

……………………

3-50

3.9.2.2 S.PTI

………………………………

3-51

3.9.2.3 F.PTI

………………………………

3-52

3.9.2.4 PTI

(使用前点検)

中のアラーム一覧

…

3-54

3.9.2.5 M.CHECK

…………………………

3-55

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

035-064̲J-SM(LXE10E-1E)A4 2007.04.27 13:29 ページ 36

https://daikin-p.ru

Summary of Contents for LXE10E-1

Page 32: ...31 7 10 7 14 Schematic wiring diagram LXE10E 1E https daikin p ru...

Page 33: ...32 https daikin p ru...

Page 34: ...33 7 11 7 15 Stereoscopic wiring diagram LXE10E 1E https daikin p ru...

Page 35: ...34 https daikin p ru...

Page 49: ...48 2 22 2 5 4 3 12 RSV CSV DEHUMID LED 1 30 RH 95 RH LXE10E 1 LXE10E 1A https daikin p ru...

Page 55: ...54 4 6 1 2 P 4 3 P 3 56 3 L LP HP LXE10E 1 LXE10E 1A LXE10E 1 LXE10E 1A https daikin p ru...

Page 58: ...57 4 18 2 120 248 F EV EV 4 2 5 TEV VTX 3410DMS 1 120 248 F https daikin p ru...

Page 66: ...65 LXE10E 1E 7 10 https daikin p ru...

Page 67: ...66 https daikin p ru...

Page 68: ...67 LXE10E 1E 7 11 https daikin p ru...

Page 69: ...68 https daikin p ru...

Page 105: ...Parts related with option 3 Indoor fanguard K1 TR06 13 104 https daikin p ru...