4-6

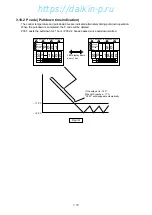

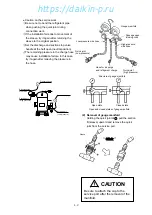

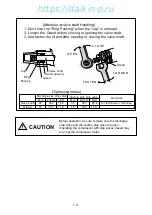

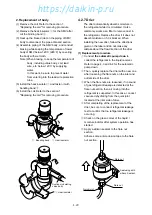

(1) Operation Pressure Check

Check high pressure from the service port

w

on the compressor discharge. Check low

pressure from the service port

q

on the

compressor suction. Then stop valves is half

open.

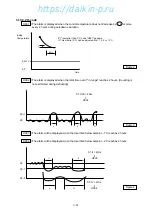

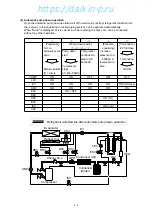

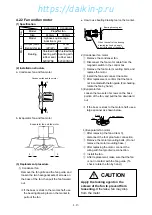

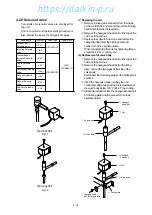

(2) Recovery non-condensable gas

If air or other non-condensable gas exists in

the refrigerant circuit, it is accumulated in the

condenser, which raises pressure in the

condenser abnormally high and reduces the

heat transfer ratio of the condenser surface

resulting in a decrease of the refrigerating

capacity. It is, therefore, very important to

remove non-condensable gas.

If the discharge pressure is abnormally high

and does not return to the normal pressure,

inspect if air or any other non-condensable

gas exists by the following procedure.

●

Conduct automatic pump down operation

(see page 4-3) and stop the unit after

collecting the refrigerant into the liquid

receiver.

Run the condenser fan by using the

condenser fan check (see page 3-56) in

the manual check functions, and wait untill

the condenser cooling air inlet/outlet

temperatures become equal. If there is

any difference between the saturated

pressure corresponding to cooling air

temperature and condensing pressure,

then non-condensable gas exists. In this

case, recover non-condensable gas as

stated below.

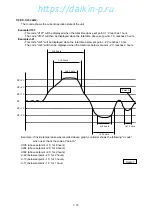

q

Conduct automatic pump down

w

Then collect the gas from the service port

w

on the compressor discharge side.

e

Reading the pressure gauge, collect the

non-condensable gas repeatedly until

condensing pressure equals saturated

pressure.

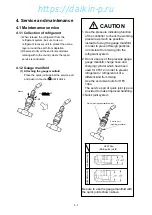

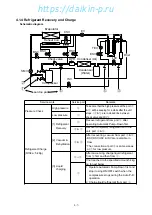

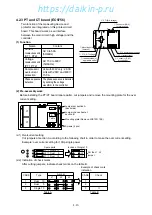

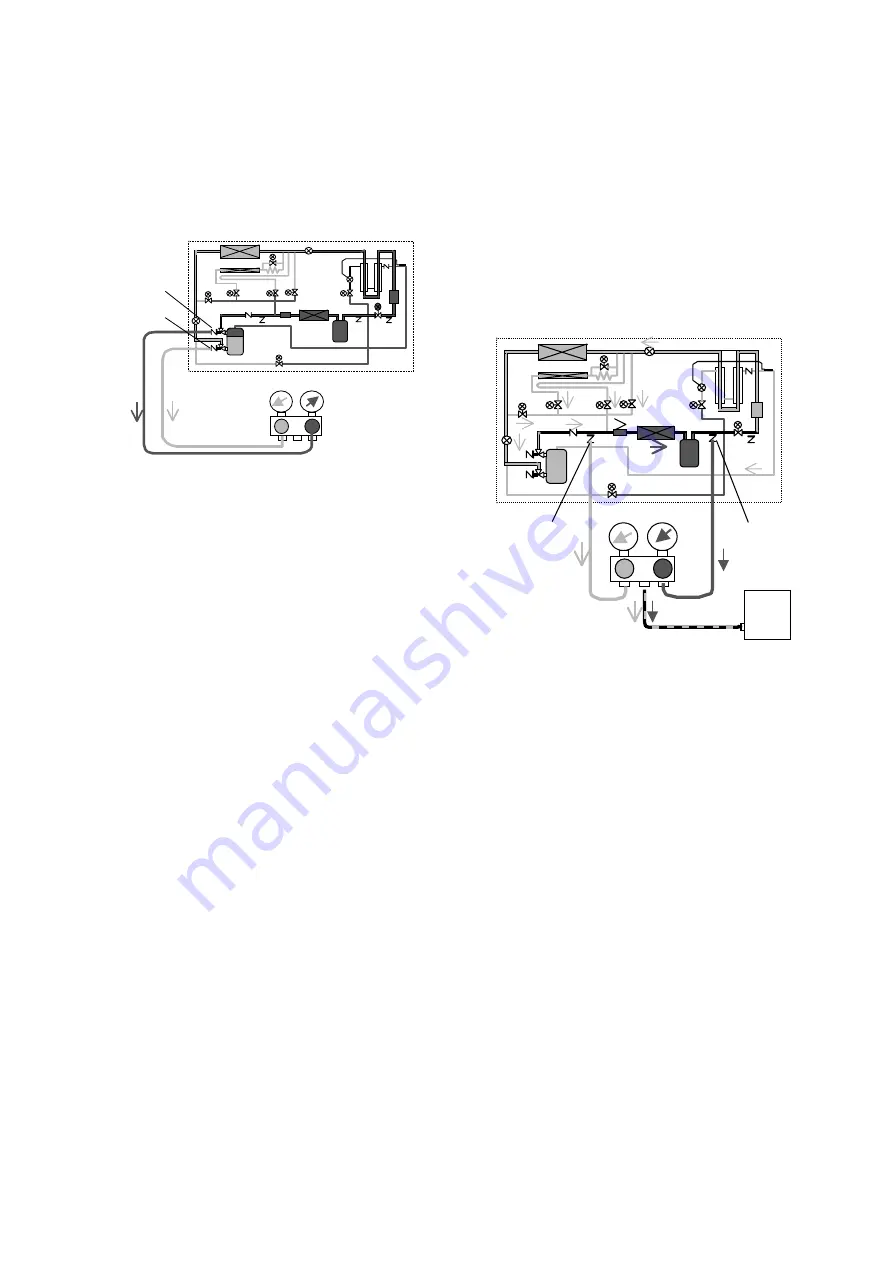

(3) Refrigerant Recovery

q

Operate Automatic Pump Dpwn.

w

Recover refrigerant from port

t

.

e

Recover completely refrigerant left in the

unit from ports

r

&

t

.

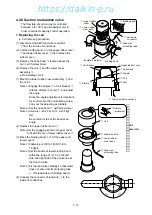

⑤

④

L

①

②

LP HP

https://daikin-p.ru