7

CAUTION

Do not expose the low pressure

transducer to hot air of a dryer for

excess time.

Otherwise, the transducer may be damaged.

5.1 Low pressure transducer (LPT)

The LPT is located in the refrigerant circuit.

The operating low pressure value is displayed

on the controller indication panel.

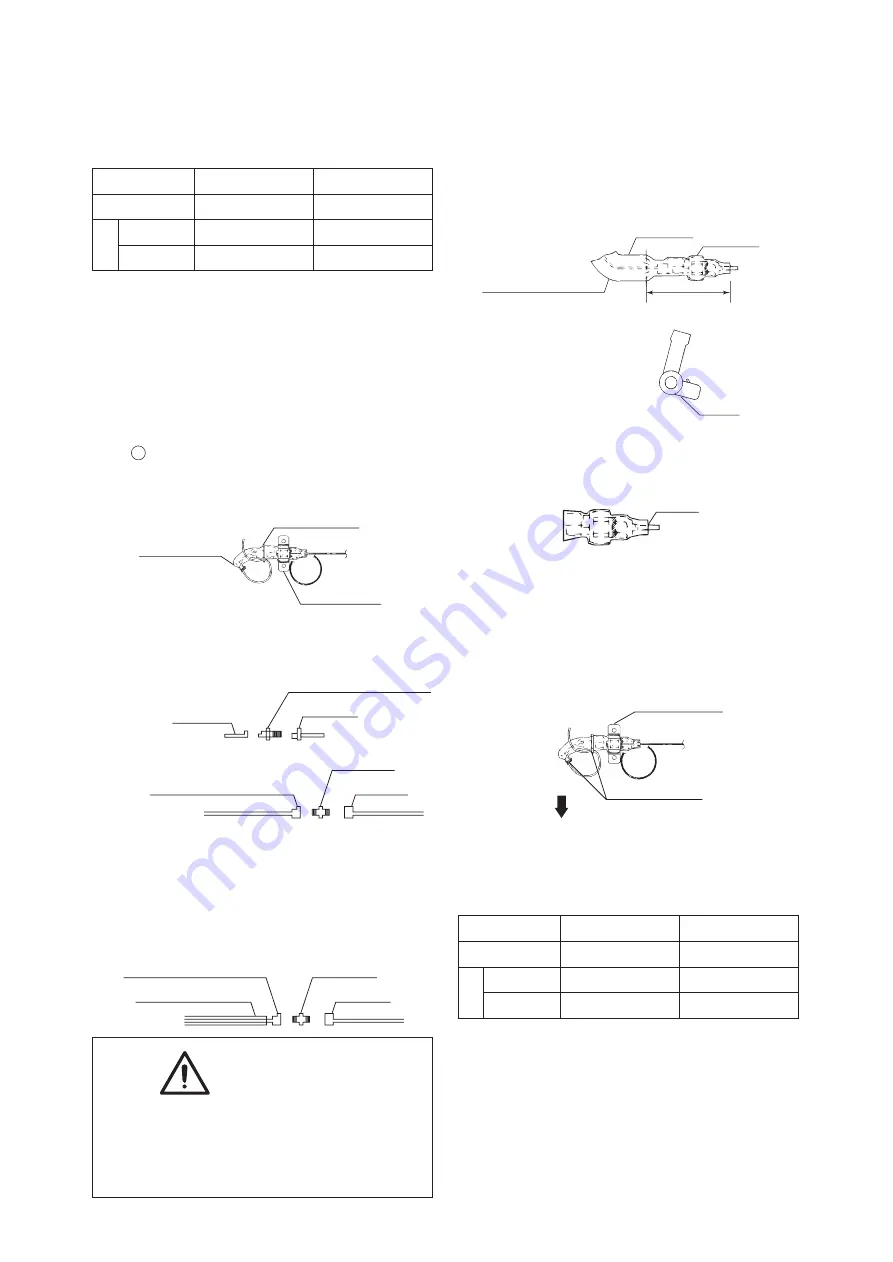

(1) Replacing the transducer

q

Disconnect the lead wire from the control box.

w

In order to prevent refrigerant from flowing

out, disconnect the low-pressure transducer

piping from the gauge joint (with check valve)

C on the compressor side.

e

Remove two screws on the clamp plate fixing

low pressure transducer in place, and cut the

binding bands.

t

Insert the pressure transducer cable through

the heat shrinkage tube, and connect the

union joint and connector to the new low

pressure transducer. If paint on the low

pressure transducer is peeled off, apply clear

lacquer.

r

Remove the heat shrinkage tube, and

disconnect the connector from the low

pressure transducer.

¡

LXE10E-A17

q

Clamp plate

w

Binding band

w

Binding band

Flare nut

Connector

Low pressure transducer

Flare nut

Union joint

Low pressure transducer

Heat shrinkage tube

Model

LXE10E-A17

LXE10E-A17A, A35, A35A

Transducer type

SPCL02

NSK-BC010F

Identification

color

Transducer

Blue seal

Black body

Connector

Blue tape

Nothing

¡

LXE10E-A17A, A35, A35A

Flare nut

Union joint

Low pressure transducer

5. Transducer

5.2 High pressure transducer (HPT)

The HPT is located in the refrigerant circuit.

The operating high pressure value is displayed

on the controller indication panel.

(1) Replacement procedure

The replacement procedure is the same as

that for the low pressure transducer.

Make sure that the fixing position and the

cable connection is correct.

y

Apply the heat shrinkage tube in the

following position, then shrink it with hot air

of a dryer.

u

Apply sealer between the heat shrinkage tube

and the flare nut. (Sealer :KE4898)

i

Fix the low pressure transducer with the

clamp plate, and fix the cable with the binding

band.

Fix the shrinkage tube end of the cable side

downward for prevention of water entering

into the tube.

r

Dryer

Make the heat shrinkage

tube fit in this area

Gauge

pipe side

Low pressure

transducer cable side

q

Heat shrinkage tube

w

Connector

e

Flare nut

q

Clamp plate

Fix the tube directing

the end downward

w

Binding band

Sealer

Model

LXE10E-A17

LXE10E-A17A, A35, A35A

Transducer type

SPCH01

NSK-BC030F

Identification

color

Transducer

Red seal

Red & Brown body

Connector

Red tape

Nothing

https://daikin-p.ru

Summary of Contents for LXE10E-A17

Page 9: ...8 https daikin p ru ...

Page 10: ...9 6 Schematic wiring diagram LXE10E A17 A17A https daikin p ru ...

Page 11: ...10 LXE10E A35 https daikin p ru ...

Page 12: ... LXE10E A35A 11 https daikin p ru ...

Page 13: ...12 7 Stereoscopic wiring diagram LXE10E A17 A17A https daikin p ru ...

Page 14: ... LXE10E A35 13 https daikin p ru ...

Page 15: ...14 LXE10E A35A https daikin p ru ...

Page 23: ...22 https daikin p ru ...

Page 24: ...23 6 シーケンス LXE10E A17 A17A https daikin p ru ...

Page 25: ...24 LXE10E A35 https daikin p ru ...

Page 26: ... LXE10E A35A 25 https daikin p ru ...

Page 27: ...26 7 実体配線図 LXE10E A17 A17A https daikin p ru ...

Page 28: ... LXE10E A35 27 https daikin p ru ...

Page 29: ...28 LXE10E A35A https daikin p ru ...

Page 81: ...MEMO https daikin p ru ...