4-6

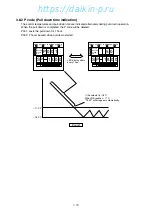

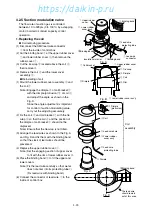

(1) Operation Pressure Check

Check high pressure from the service port

w

on the compressor discharge. Check low

pressure from the service port

q

on the

compressor suction.

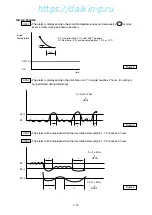

(2) Recovery non-condensable gas

If the air or other non-condensable gases

are present in the refrigeration system, they

will gather in the condenser and the

pressure inside the condenser will rise

significantly and the thermal conductivity of

the condensing surface will be decreased,

resulting in deterioration of refrigeration

performance. Therefore, it is very important

to eliminate the non-condensable gases.

If the discharge pressure is abnormally high

and the pressure is not normalized, check

whether the air or other non-condensable

gases are present by following the

procedure below.

●

After carrying out the automatic pump-

down operation to collect the coolant in the

liquid receiver, stop the unit once. Operate

the condenser fan in accordance with the

condenser fan check procedure included in

the manual check procedure, and wait until

the cooling air inlet and outlet

temperatures become equal. Non-

condensable gases are present if there is

any difference between the saturation

pressure and the condensation pressure

corresponding to the temperature of the

cooling air.

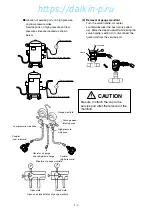

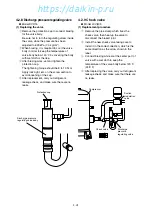

(3) Refrigerant Recovery

q

Operate Automatic Pump Dpwn.

w

Recover refrigerant from port

t

.

e

Recover completely refrigerant left in the

unit from ports

r

&

t

.

t

w

q

LP

HP

t

r

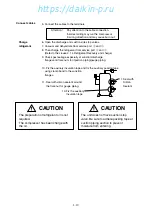

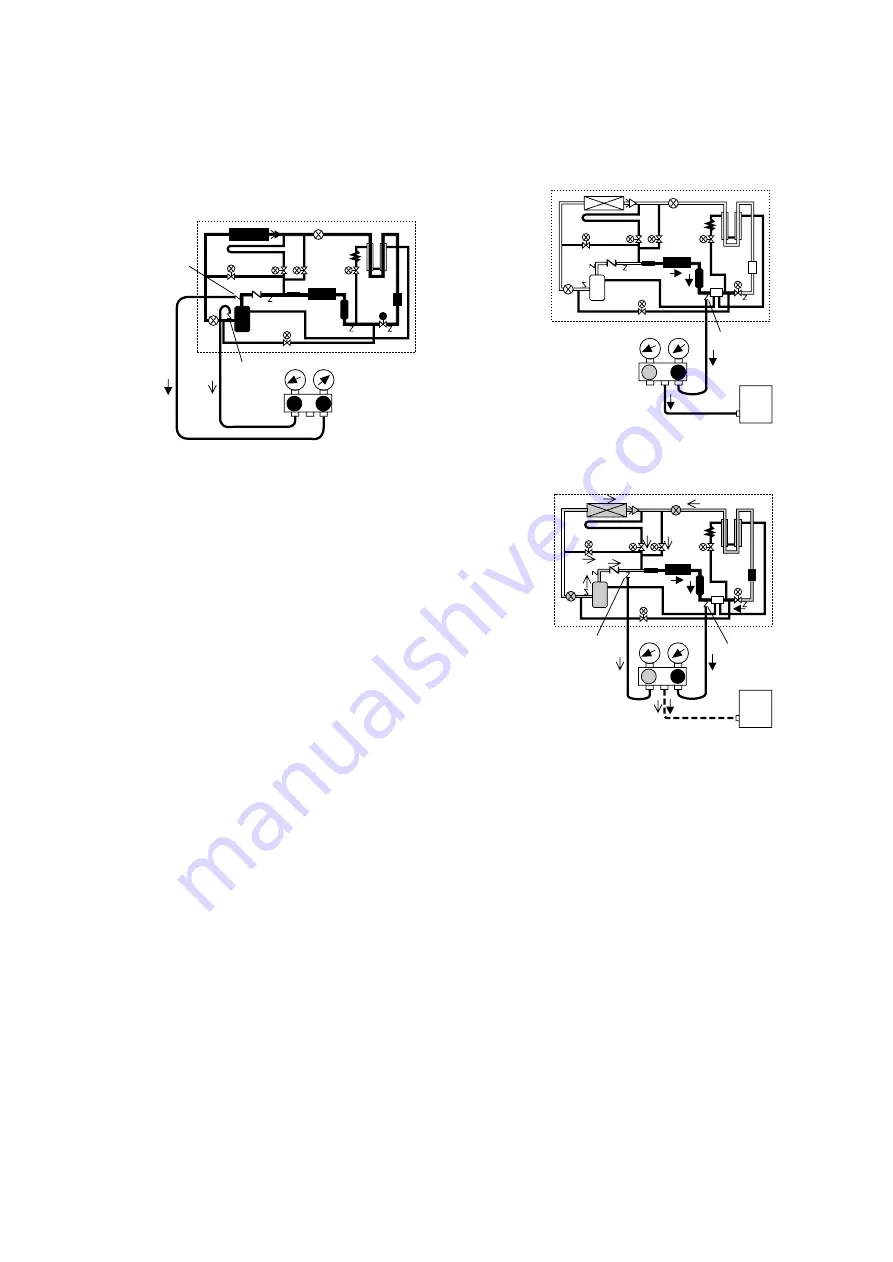

(4) Vacuum-dehydrating, and refrigerant /

charging

If all the refrigerant has leaked out and air is

intermixed in the refrigeration circuit, remove

the cause of trouble and carry out vacuum-

dehydrating. Then charge the specified

amount of refrigerant.

[Required tools]

1. Refrigerant cylinder (content of 20kg)

equipped with joint for HFC134a

2. Gauge manifold with quick joints

3. Weighing scale (up to 50kg)

4. Vacuum pump

https://daikin-p.ru