4-19

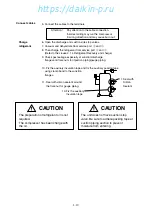

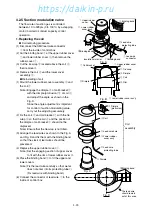

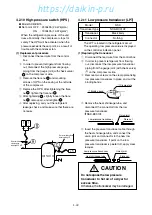

2. Replacement of body

(1) Remove the coil. Refer to the section 1.

"Replacing the coil" for removing procedure.

(2) Remove the heat insulator

q

for the SMV after

cut the binding band

w

.

(3) Heat up the brazed joint on the piping of SMV

body to disconnect the pipe at brazed section.

(4) Assemble piping of the SMV body, and conduct

brazing while keeping the temperature of lower

body of SMV below 120˚C (248˚F) by covering

the body with wet cloth.

Note) When brazing, to keep the temperature of

body, including value body, coil, lead

wire, etc. below 120˚C by supplying

water.

In this work, be sure to prevent water

from entering into the lead wire protection

tube.

(5) Install the heat insulator

q

and fasten it with

bandling band

w

.

(6) Install the coil. Refer to the section 1.

"Replacing the coil" for removing procedure on

the previous page.

w

Bandling band

q

Heat insulator

q

Heat insulator

Suction modulating

valve body

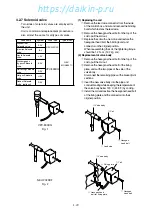

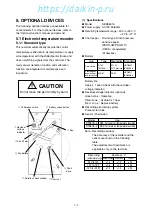

4.2.6 Drier

The drier automatically absorbs moisture in

the refrigerant while it is circulated. It also

commonly works as a filter to remove dust in

the refrigerant. Replace the drier if it does not

absorb moisture, is blocked, or if the system

has been opened to the atmosphere. When

installing the new drier, follow the arrow and

do not make any mistake about the installation

direction of the drier

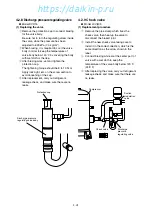

(1) Replacement procedure

q

Conduct

the automatic pump down

to

collect the refrigerant in the liquid receiver.

Refer to page 4-3 and 4-4 for the automatic

pump down.

w

Then, quickly replace the drier with a new one

after loosening the flare nuts on the inlet and

outlet side of the drier.

e

After completing of the replacement of the

drier, be sure to conduct refrigerant leakage

test to confirm that no refrigerant leakage is

occuring.

r

Check on the green colour of the liquid /

moisture indictor after system operation has

started.

t

Apply silicon sealant to the drier body including

the flare nuts on the inlet and outlet sides

Outlet flare nut

Inlet flare nut

Quick joint

①

②

③

Fully apply silicon sealant to

the drier body including the

flare nuts on the inlet and

outlet sides

When put under low

temperature and pressure by

some operation conditions,

①

and

②

might have the threads

damaged by frozen dew drops.

③

may become rusty as a

result of coating peel-off at

work using a spanner

https://daikin-p.ru