4-1

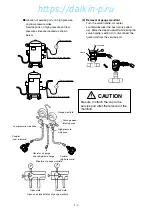

CAUTION

1. Use the pressure indicating function

of the controller to check the working

pressure as much as possible

instead of using the gauge manifold

in order to prevent foreign particles

or moisture from mixing into the

refrigerant system.

2. Do not use any pressure gauge,

gauge manifold, charge hose and

charging cylinder that has been used

for CFC12 in order to prevent

refrigerant or refrigerant oil of a

different kind from mixing.

Use the exclusive tools for HFC

134a.

3.The service port of quick joint type is

provided to make improved handling.

※

Quick joint system

4. SERVICE AND

MAINTENANCE

4.1 Maintenance service

4.1.1 Collection of refrigerant

q

When releasing the refrigerant from the

refrigerant system, be sure to use a

refrigerant recovery unit to protect the ozone

layer around the earth from depletion.

w

Observe strictly all the environmental laws

relating with to the country where the repair

service is conducted.

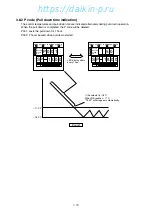

4.1.2 Gauge manifold

(1) Attaching the gauge manifold

Turn the valve handle of coupler

counterclockwise (the push pin is pulled

up). Slide the sleeve upward, and press it

against the service port. Then, securely

push the valve handle (section A) until a

click sound is heard. After the coupler is

inserted into the service port, release the

sleeve. The coupler is fixed so that it is not

detached from the service port.

Next, turn the valve handle clockwise.

Lower the push pin, and open the check

valve at the service port.

A

Sleeve

Valve handle

Turn the valve

handle

Be sure to use the gauge manifold with

the quick joints shown above.

High pressure side

Low pressure side

HFC134a

(SAE quick joints)

Note: Do not fully turn the valve handle clockwise.

Otherwise, the push pin may be broken.

https://daikin-p.ru