15

IOM 1297

WWW.DAIKINAPPLIED.COM

ELECTRICAL

Electrical

Field Power Wiring

The standard power wiring connection to Magnitude chillers is

single-point for WMT models. Power conduit entry will be at the

side of the unit power panel; see

for general reference

as power entry cover plate location will vary by unit configuration.

Copper wiring must be used for power wiring. Refer to the unit

nameplate and the Daikin Tools selection report for the correct

electrical ratings.

DANGER

Qualified and licensed electricians must perform wiring. An

electrical shock hazard exists that can cause severe injury or

death.

Figure 13: Unit Power Connection Point

NOTICE

Top entry is only allowable under certain conditions. Contact

factory for assistance.

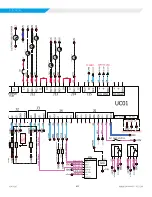

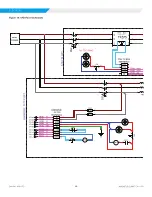

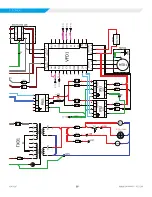

The field control wiring required varies depending on unit model.

See the field wiring schematic for wiring information. These wiring

diagrams are also provided with the chiller.

NOTICE

Wiring, fuse, and wire size must be in accordance with the

National Electrical Code

®

(NEC). The voltage to these units must

be within ±10% of nameplate voltage (415V units must have

voltage within -13% and +6% of nameplate voltage) and the

voltage unbalance between phases must not exceed 2%. Since

a 2% voltage unbalance will cause a current unbalance of 6 to 10

times the voltage unbalance per the current version of the NEMA

MG-1 Standard, it is most important that the unbalance between

phases be kept at a minimum.

CAUTION

Do not use power factor correction capacitors with WMT chillers.

Doing so can cause harmful electrical resonance in the system.

Correction capacitors are not necessary since VFDs inherently

maintain high power factors.

Use with On-Site Generators

All Magnitude Model WMT chillers have their compressors

operated with variable frequency drives and can be used in

applicatinos where they may be required to run with an on-site

electrical generator. This is helpful when the generators are used

for temporary power when the utility power is lost.

Generator Sizing

Natural gas and diesel generators are sensitive to the peak

current loads of the chiller. Although the normal VFD start

sequence does not require these peak values of current,

certain dynamic conditions such as changes in water flow and

temperature or momentary power interruptions can cause high

peak electrical currents. Use the electrical data either on the VFD

data plate or supplied with the chiller performance rating sheet

– obtained from the Daikin Applied sales office – for generator

sizing purposes. The referenced data will show the RLA and

LRA. It is important to size the generator to handle the LRA

value.

WARNING

Generator must be sized by an electrical engineer familiar with

generator applications.

Transfer Back to Grid Power

Due to the special VFD incorporated in all WMT chillers and the

system’s inherent ride-through capabilities, transfer from grid

power to stand-by generator power and back to grid power can

be done at any time. The duration of power interruption during

the transfer process will determine how the chiller will respond.

While the compressor rotor is still spinning at adequate speed,

power is generated internally to keep the bearings and all control

electronics operating. Power interruptions of various durations

will cause different restart scenarios as described below.

1 .

Short:

Interruptions of only a few seconds will allow a

running compressor to return to operating speed almost

immediately. (NOTE: If the operating pressure ratio is high

at the time of interruption, there may be a short delay in

return to operating speed.)

2 .

Medium:

For interruptions that cause the compressor to

coast down below about 3500 rpm (but still generating

control power), the compressor will continue coasting to a

stop, and then restart.

3 .

Long:

Once the compressor coasts nearly to a stop,

control power is lost and the controllers must reboot

normally when either grid power or emergency generator

power is reinstated. (NOTE: If the RapidRestore option is

installed, the time required to restart is reduced to only a

few seconds).