37

IOM 1297

WWW.DAIKINAPPLIED.COM

OPERATION

•

For 2 stages:

• 1 on E*1 TCLO and tower valve > 90%, 2 on E*2

TCLO and tower valve = 100%

• 2 off D*2 TCLO, 1 off D*1 TCLO

•

For 3 3 stages:

• 1 on E*1 TCLO and tower valve > 90%, 2 on E*2

TCLO and tower valve = 100%, 3 on E*3 TCLO and

tower valve = 100%

• 3 off D*2 TCLO, 2 off D*1 TCLO, 1 off D*.5 TCLO

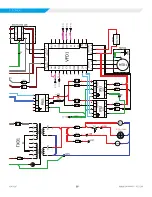

Figure 38: Chiller Unit Tower Control

BAS Tower Control

In the above control strategies, the chiller unit controller is directly

controlling the cooling tower fan stages, variable frequency

drives, and bypass valve. As an alternative, a BAS can control

these components based on the 0-10 VDC signals for the tower

fan VFD and tower bypass valve or condenser pump VFD. See

.

Figure 39: BAS Tower Control

Figure 40: Settings View - Valves

Table 11: Valve Setpoint Settings

Description

Default

Range

PW

Comments

EXV - Capacity Control

EXV Gain

78

20-400

T

Gain selection based

on chiller size and

valve type.

EXV Evap

Weight

1

-100 to

100

1

Weight selection based

on chiller size and

valve type

Figure 41:

Settings View - Offsets

Condenser

MicroTech

®

Controller

0-10 VDC

Signal

Bypass Line

0-10 VDC Signal

Bypass

Valve

Cooling Tower

Fan Staging

(Up to 2 fans)

Tower

Control

Panel

w/ Fan

VFD

Condenser

MicroTech

®

Controller

Bypass Line

0-10 VDC Signal

BAS

Tower

Control

Panel

w/ Fan

VFD