INSTALLATION

MAGNITUDE WMT CHILLER

DAIKIN APPLIED

6

Clearance

The unit must be placed in an area that allows for adequate

clearance around the unit. See

Figure 6

for clearance

requirements around the sides of the chiller. Doors and

removable wall sections can be utilized to meet these clearance

requirements. There must be a minimum 3-foot clearance above

the top of the chiller. The U.S. National Electrical Code

®

(NEC) or

local codes can require more clearance in and around electrical

components and must be checked for compliance.

Mounting

The unit must be mounted on a concrete or steel base. Make

sure that the floor or structural support is adequate to support the

full operating weight of the complete unit.

WMT chillers are nearly vibration-free. Consequently, floor

mounted spring isolators are not usually required. Neoprene

mounting pads are shipped with each unit. It is recommended

to continue to use flexible piping connectors to reduce sound

transmitted into the pipe and to allow for expansion and

contraction.

It is not necessary to bolt the unit to the mounting slab or

framework. Should this be required by local codes, 1-1/8 inch

(1.125 inch, 28.5 mm) mounting holes are provided in the unit

supports at the four corners. When mounted, the base pad of the

unit must be level to within ± 1/2 inch (0.5 inch,12.7 mm) across

the length and width of the unit.

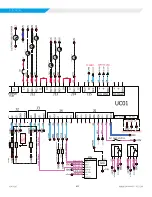

1 .

Units with single point power, 575V, and/or the optional

harmonic filter will require additional panels than shown in

Figure 7

.

Lifting Guidance

Daikin Applied equipment is designed to withstand the loads of

the lifting and rigging process resulting from ASME Standard

P30.1 - Planning for Load Handling Activities or equivalent.

Lifting guidance is intended for installations of newly delivered

equipment. If moving previously installed equipment for re-

location or disposal, consideration should be given to unit

condition. Equipment should also be drained as unit weight and

center of gravity values do not reflect the addition of water for

lifting.

DANGER

Improper rigging, lifting, or moving of a unit can result in unit

damage, property damage, severe personal injury or death. See

the as-designed, certified dimensioned drawings included in the

job submittal for the weights and center of gravity of the unit. If

the drawings are not available, consult the local Daikin Applied

sales office for assistance.

Installation is to be performed only by qualified personnel who

are familiar with local codes and regulations, and experienced

with this type of equipment. Lifting equipment and mechanisms

must be determined by the Lifting Director per the current version

of ASME Standard P30.1 or equivalent and must be suited for the

load capacity.

Daikin Applied is not a licensed nor certified rigging specialist.

Therefore it is the customer’s responsibility to consult a certified

rigging contractor to rig, lift, and move components and

subcomponents properly and safely as needed.

CAUTION

Forklifts may not be used to lift or move WMT units as the

method may result in unit damage.

CAUTION

When around sharp edges, wear appropriate Personal Protective

Equipment (PPE), such as gloves, protective clothing, foot wear,

eye protection, etc. to prevent personal injury.

Lifting Brackets

Lifting bracket designs vary from product to product. Rules of

engagement with the lifting brackets are the same regardless of

the bracket type.

For

WMT

units, a typical lifting bracket with 2ʺ (51 mm) diameter

holes found on the upper corners of each end cap are illustrated

in

. See the as-designed certified drawings for specific

lifting points on this product model.

Engagement with each bracket is to be as close to vertical as

possible. The maximum allowable lift angle from the vertical is 30

. If the lift angle shifts beyond 30°

from vertical on any of the lift points, the lift shall not proceed until

a plan and rigging can be secured that will correct the angle of

lift.

WARNING

The lifting angle must not go beyond 30 degrees from vertical or

the unit can become unstable which may result in unit damage,

property damage, severe personal injury, or death.

Figure 2: Illustration of Lifting Bracket and Allowed Angle for

Lifting