7

IOM 1297

WWW.DAIKINAPPLIED.COM

INSTALLATION

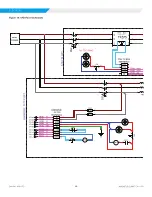

Figure 3: Illustration of Allowed Angle Label

Lifting Equipment

Lifting equipment is supplied by the user or their designate.

This is typically selected around the unit certified information

of the equipment to be lifted and the available lifting equipment

planned to be at the site where the lift is to take place. It is the

responsibility of the Lifting Director to follow a standard practice

of lift planning and equipment selection, like that found in the

ASME P30 series of standards. Lifting plan and equipment must

ensure that the only contact with the unit is at that lifting brackets.

Straps, chains or spreader bars that are likely to be used shall

not come in contact with the unit.

CAUTION

Lifting mechanisms must not make contact with the unit beyond the lifting

bracket. Extreme care must be used when rigging the unit to prevent damage

to the control panels, unit handles, and unit frame.

Lifting Points

Lifting points are predetermined by design. When lifting, all

factory installed lifting brackets must be used.

typical 4 point and 6 point lifting configurations. Unit must remain

level throughout the entire lifting event. Level is defined as

one end being no more than 0.25” per foot of unit length to the

opposite end.

WARNING

Be aware that the center of gravity may not necessarily be in the geometric

center of the unit. No additional items can be added to a lift with the unit as

it may affect the center of gravity and cause unit damage, property damage,

severe personal injury, or death. Refer to as-designed, certified drawings for

weight, center of gravity location and details specific to unit configuration.

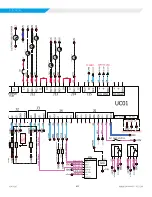

Figure 4: Typical Lifting Points Locations

Transit and Temporary Storage

If the unit is stored for an intermediate period before installation

or moved to a different location, take these additional

precautions:

1 .

Support the unit well along the length of the base rail.

2 .

Level the unit (no twists or uneven ground surface).

3 .

Provide proper drainage around the unit to prevent flooding

of the equipment.

4 .

Provide adequate protection from vandalism, mechanical

contact, etc.

5 .

Securely close the doors and lock the handles

6 .

Cover the supply and return air openings on units without

isolation dampers.

7 .

Long term storage in humid environments may cause

condensate corrosion on steel surfaces. Consider adding a

desiccant material to alleviate corrosion concerns.

Long Term Storage

This information applies to new units being stored waiting for

startup or existing units that may be inoperative or in storage for

four

months or more.

The chiller must be stored in a secure, dry location and protected

from any damage or sources of corrosion while in storage. A

Daikin Applied service representative must perform a leak test

and visual inspection for any damage or unusual conditions

affecting the unit on a minimum quarterly schedule, to be paid

by the owner or contractor. Daikin Applied will not be responsible

for any refrigerant loss during the storage time, for repairs to

the unit during the storage period, or while moving the unit from

the original location to a storage facility and back to any new

installation location. If there is concern about the possibilities of