IOM 1210-7 • MAGNITUDE

®

MODEL WMC CHILLERS

14 www.DaikinApplied.com

I

nsTallaTIon

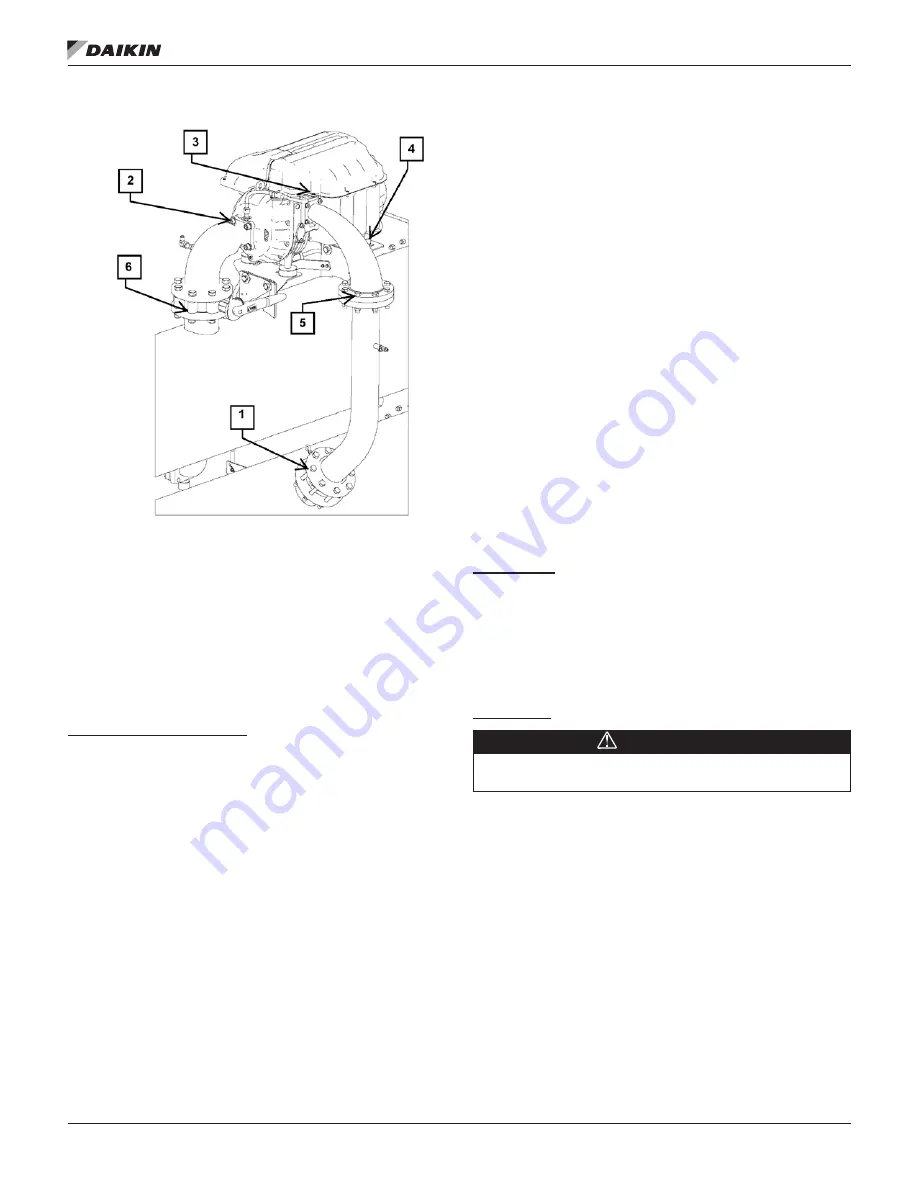

Figure 13:

Compressor Removal / Re-Attachment

2. Remove bolts at discharge elbow connection to

discharge line (flag #5) and install a flange cover.

Warning: Do not loosen bolts at discharge check valve.

(flag #1)

3. Loosen the (4) bolts from the compressor’s bottom

, flag #4).

NOTE:

Do not loosen or remove bolts securing the

compressor brackets as height is pre-set from

the factory.

Compressor Re-Attachment

1. Set compressor on mounting brackets and install the (4)

mounting bolts loosely.

2. Reinstall suction and discharge elbows with new gaskets

and O-rings.

3. Re-attach all associated power wiring and compressor

control cable.

4. Reconnect motor cooling liquid line.

5. Evacuate the evaporator and compressor(s) to 500

microns and perform a standing hold to verify no

moisture or leaks.

6. After verifying that pumps are running and water flow

has been established on both evaporator and condenser,

add vapor refrigerant to bring the saturated temperature

above freezing. Open all valves.

7. Perform refrigerant leak check to ensure all connections

and fittings are securely fastened.

Knockdown Disassembly and

Reassembly Instructions

Type A

Type A units are designed for a wide range of disassembly

and the degree of knockdown varies. Observe the following

recommendations.

1. The chiller is shipped with the full refrigerant charge,

which must be recovered before breaking any refrigerant

connection. Before attempting any disassembly, assume

the condenser isolation valves may have leaked and that

any component of the chiller may be pressurized with

refrigerant. Exert the proper precautions with this caveat

in mind.

2. Check that power has been removed from the unit.

Before disconnecting any wire, it is prudent to label its

function and connection point to facilitate reconnection.

3. The refrigerant charge must be removed from the unit if

the vessels are to be separated.

4. Some insulation repair and touch-up painting may be

required.

5. See Type B instructions for reassembly of components.

Type B

Disassembly

Type B Knockdown units are shipped disassembled except for

the vessel stack and are shipped less refrigerant. If the stack

size or weight dictates further disassembly, the vessels can

be separated by disconnecting any interconnecting wiring and

tubing and then unbolting them. The vessels and compressors

have an inert gas holding charge that must be released prior to

attempting to open any connection.

Reassembly

CAUTION

Standard torque specs must be followed when re-installing

bolts. Contact Daikin Applied service for this information.

1. Reassemble the vessel stack, if disassembled, and

reconnect any wiring and tubing.

2. Mount the compressor(s) on the stack. Be careful to

avoid damaging lines already mounted on the unit.

Mounting bolts, washers and nuts are shipped loose.

Leave the mounting bolts loose until the suction and

discharge lines are installed and aligned.

During assembly, bolts holding block off plates (suction

connection, for example), are used for reassembly of the

component. See

for the location

of the block offs.

3. Do not remove block offs until ready to install piping.

The compressor and vessels have a Schrader valve on

their block off plates to be used for relieving the inert gas

holding charge.