I

nsTallaTIon

IOM 1210-7 • MAGNITUDE

®

MODEL WMC CHILLERS

18 www.DaikinApplied.com

Water Side Economizer Cycle Operation

Water side economizers are commonly used for ASHRAE 90.1

compliance and energy savings. This system utilizes a heat

exchanger external to the chiller when cold cooling tower water

is available to provide cooling. The most common system

has a heat exchanger used in conjunction with the chiller’s

evaporator.

The BAS contractor will need to provide controls for the heat

exchanger including isolation valves and temperature control.

The BAS contractor will also need to control the isolation

valves for the chiller. It is important to use slow-acting type

valves to prevent rapid changes in system flows. Changeover

from economizer cooling to mechanical cooling requires one

of the methods previously mentioned to maintain suitable

condenser head pressure.

Contact your local Daikin Applied representative for more

information on this application.

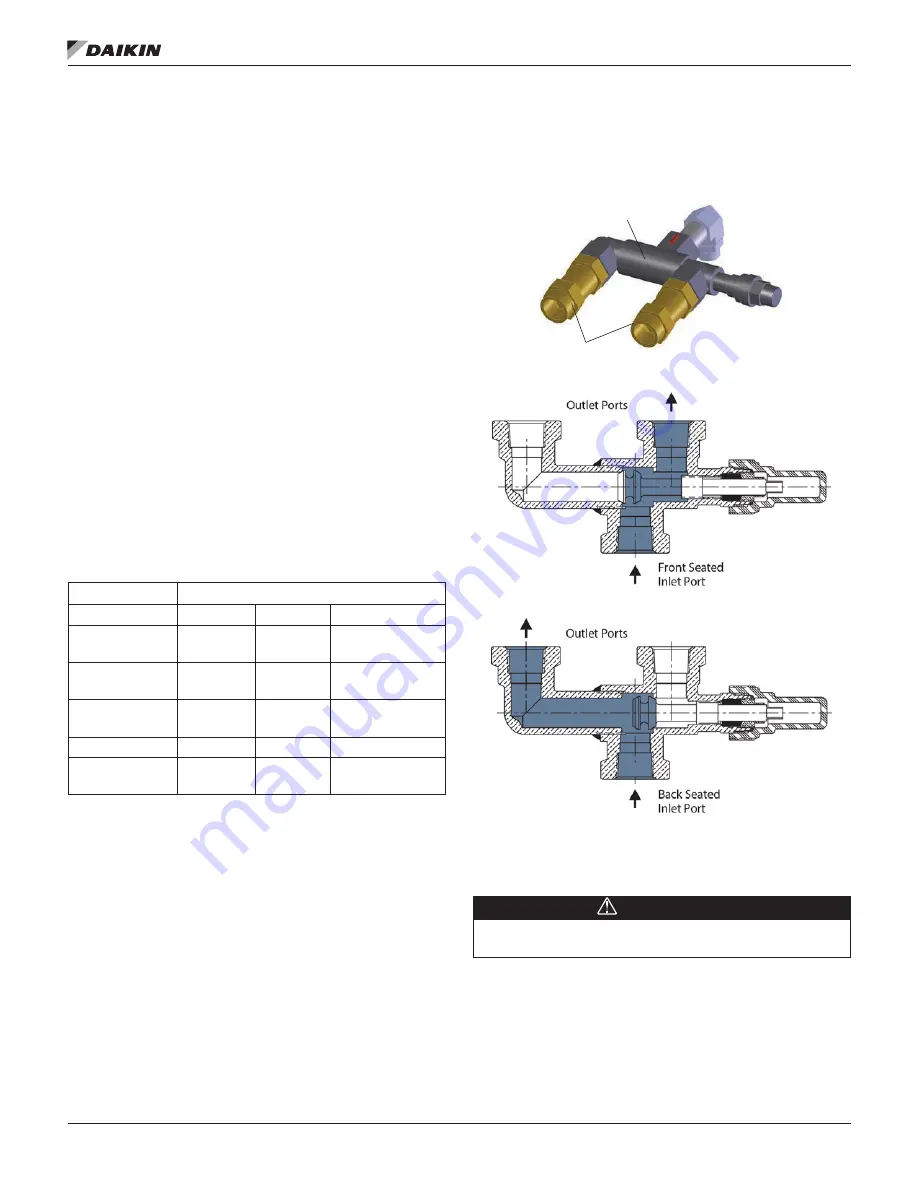

Relief Valves

As a safety precaution and to meet code requirements, each

chiller is equipped with pressure relief valves located on the

condenser, evaporator, and compressor suction line(s) for the

purpose of relieving excessive refrigerant pressure (caused by

equipment malfunction, fire, etc.) to the atmosphere.

Table 6:

Relief Valve Data

Chiller

WMC

Relief Valve

Evaporator

Condenser

Suction Line*

Location

Top of

evaporator

Top of

condenser

Each suction line

Pressure Setting

(psi)

200

225

200

Discharge Cap.

(lb/min air)

75.5

84.4

6.9

Qty

1

2

1 per compressor

Connection Size

1.0-inch

female NPT

1.0-inch

female NPT

3/8-inch flare

Most codes require that relief valves be vented to the outside

of a building. Relief piping connections to the relief valves must

have flexible connectors.

Remove plastic shipping plugs (if installed) from the inside of

the valves prior to making pipe connections. Whenever vent

piping is installed, the lines must be in accordance with local

code requirements; where local codes do not apply, the latest

issue of ANSI/ASHRAE Standard 15 code recommendations

must be followed.

Condenser Relief Valves

In order to ensure proper installation, it is important to know

how the three-way relief valve functions. One valve remains

active at all times and the second valve acts as a standby.

When the stem of the three-way valve is pushed into the

valve completely, the valve is in “Front Seated Position” and

all refrigerant will flow through the back outlet port, as shown

in

. When the stem of the three-way valve is pulled

back completely, the valve is in “Back Seated Position” and all

refrigerant will flow through the front outlet port as shown in

Figure 16:

Condenser Three-Way Relief Valve

Figure 17:

Three-Way Valve, Front Seated Position

Figure 18:

Three-Way Valve, Back Seated Position

When the valve stem is not pushed forward or pulled back

completely, the valve is in “Mid Position,” as shown in

CAUTION

Do not operate the system with the three-way valve stem in

the Mid Position.

Three-Way Valve

Relief Valves