IOM 1210-7 • MAGNITUDE

®

MODEL WMC CHILLERS

6

www.DaikinApplied.com

I

nsTallaTIon

I

nsTallaTIon

Nameplates

There are several identification nameplates on the chiller:

• The unit nameplate is located on the exterior of the Unit

Control Panel. Both the Model No. and Serial No. are

located on the unit nameplate; the Serial No. is unique to

the unit. These numbers should be used to identify the

unit for service, parts, or warranty questions. This plate

also has the unit refrigerant charge and electrical ratings.

• Vessel nameplates are located on the evaporator and

condenser. They have a National Board Number (NB)

and a serial number, either of which identify the vessel

(but not the entire unit).

Receiving and Handling

The unit should be inspected immediately after receipt for

possible damage. All Daikin Applied centrifugal water chillers

are shipped FOB factory and all claims for handling and

shipping damage are the responsibility of the consignee.

On units with factory-installed insulation, the insulation

is removed from the vessel lifting hole (also used for

transportation tie-downs) locations and is shipped loose. It

should be secured in place after the unit is finally placed.

Neoprene vibration isolation pads are shipped loose in the

power panel. If the unit is equipped with a shipping skid, leave

the skid in place until the unit is in its final position. This will aid

in handling the equipment.

CAUTION

Extreme care must be used when rigging the unit to prevent

damage to the control panels and refrigerant piping. See the

certified dimension drawings included in the job submittal for

the weights and center of gravity of the unit. If the drawings

are not available, consult the local Daikin Applied sales office

for assistance.

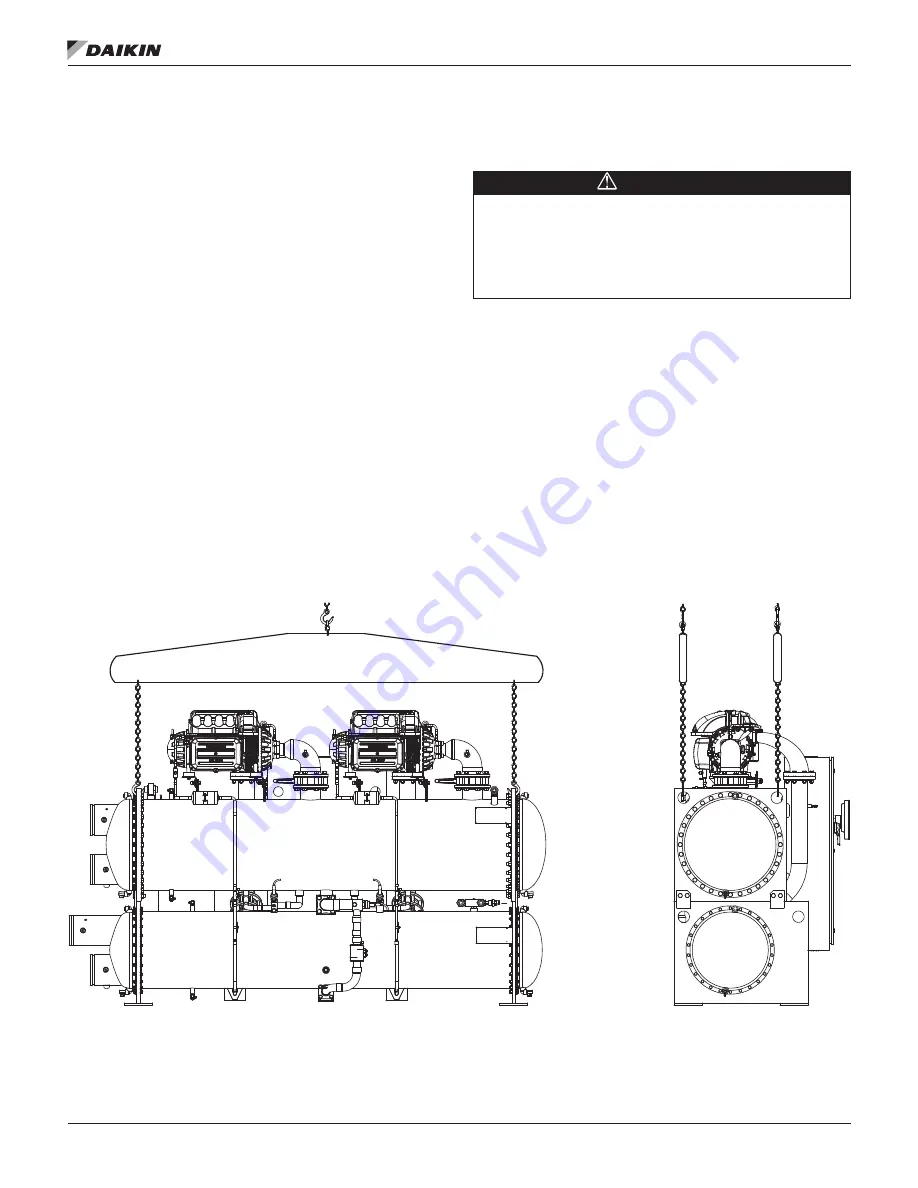

The unit can be lifted by fastening the rigging hooks to the four

corners of the unit where the rigging eyes are located — see

. A spreader bar must be used between the rigging

lines to prevent damage to the control panels, piping, and

electrical panels. The spreader-bar length should be equal

to, or no more than 1-foot shorter than, the distance between

the lifting holes located at opposite ends of the chiller. The

unit will require a single spreader-bar of this length capable

of supporting 1.5 times the shipping weight of the unit.

Separately, all cables and hooks by themselves must also be

capable of supporting 1.5 times the shipping weight of the unit.

If a knockdown option was ordered on the unit, reference the

information.

Figure 5: WMC Unit Rigging

NOTE:

The spreader bars in

are a representation only and may not reflect the appearance of the actual spreader bars

needed.

LEFT VIEW

REAR VIEW