OM 1077-1 • MAVERICK I 14 www.DaikinApplied.com

s

equenCe

of

o

peraTIon

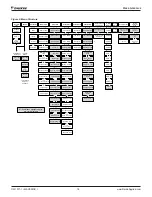

Pre-Purge

The IFC energizes the low inducer motor, flashes code “2” on

LED, and waits for the low pressure switch to close. If the low

pressure switch does not close within 3 minutes, the control will

energize the high inducer and wait for both pressure switches

to close. The IFC will light on high fire and remain on high fire

for the remainder of the heat cycle.

When the low pressure switch has closed, the IFC stops

flashing the LED and begins timing the 30 second pre-purge

period. If flame is sensed as present during pre-purge, the

IFC restarts the pre-purge time to require a full pre-purge after

flame is removed. When pre-purge time has expired, the IFC

begins the ignition trial.

Ignition Trial

The IFC energizes the gas valve and spark. The IFC ignores

flame sense for the first 2 seconds of the ignition trial. If flame

is not established within 7 seconds, the gas valve and spark

is de-energized and the IFC goes to an inter-purge. If flame is

established, the spark is de-energized, the IFC energizes the

high inducer (low inducer remains energized) and begins heat

blower on delay.

Heat Blower On-Delay

The control waits for 45 second heat fan on delay and then

energizes the indoor blower heat speed. If the blower is

already energized by a call for cooling or continuous fan, or

in a blower off delay period, the on delay is skipped and the

blower remains energized. After the blower on delay time is

complete, the control goes to high fire warm-up mode.

The high pressure switch is ignored during the heat blower

on delay to give time for the high pressure switch to close if

lighting on low fire.

High-fire Warm-up

The IFC remains on high fire for 120 seconds after flame is

established. If the DDC Controller is calling for 2nd stage heat,

the IFC remains in high heat. If the IFC lit on high fire because

the low pressure switch did not close within 3 minutes, then the

IFC remains on high fire for the entire call for heat regardless

of 2nd stage thermostat call. If there is no DDC Controller

demand for 2nd stage heat when the 120 second time has

expired, the IFC transitions from high heat to low heat.

Low Heat

IFC inputs are continuously monitored to ensure limit, rollout,

and pressure switches are closed, flame is established, and

the thermostat call for heat remains. Low gas, low inducer, and

blower remain energized. If the DDC Controller calls for 2nd

stage heat (Hi Heat), the IFC transitions to high heat.

High Heat

IFC inputs are continuously monitored to ensure limit, rollout,

and pressure switches are closed, flame is established, and

the DDC Controller calls for heat remain. Low gas, high gas,

low inducer, high inducer, and blower remain energized. If the

DDC Controller terminates the call for 2nd stage heat and the

first stage call remains, the IFC transitions to low heat.

Low Heat to High Heat Transition

When the DDC Controller calls for 2nd stage heat after low

heat is established, the IFC checks the high pressure switch.

If the high pressure switch is closed, the IFC flashes “2” on

the LED and waits indefinitely for the high pressure switch

to open. When the high pressure switch is proven open,

the IFC energizes the high inducer motor and waits for the

pressure switch to close. If the high pressure switch does

not close within 60 seconds, the control flashes “2” on the

LED and deenergizes the high inducer motor for 5 minutes.

The high inducer is re-energized after the 5 minute period for

60 seconds and the cycle repeats indefinitely until the high

pressure switch closes. When the high pressure switch closes,

the IFC energizes the high gas output and proceeds to high

heat.

High Heat to Low Heat Transition

When the DDC Controller ends the call for 2nd stage heat and

the first stage call remains, the IFC de-energizes the high gas

output. The high inducer remains energized for 60 seconds

after the high gas de-energizes. The IFC proceeds to low heat.

Post Purge

When the DDC Controller demand for heat is satisfied, the

IFC immediately de-energizes the gas valve(s). The Inducer

output(s) remains on for a 5 second post-purge period. The

IFC continues the heat blower off delay.

Heat Blower OFF Delay

The IFC de-energizes the Indoor blower motor 90 seconds

after the call for heat terminated

Interrupted Call For Heat

If the DDC Controller demand for heat is removed before

the ignition period, the IFC will immediately de-energize the

inducer.

If the DDC Controller demand for heat is removed after ignition

has begun, the induced draft motor will run through a post

purge and the indoor blower motor will run on heat speed for

the delay OFF time.