s

equenCe

of

o

peraTIon

www.DaikinApplied.com 13

OM 1077-1 • MAVERICK I

s

equenCe

of

o

peraTIon

IMPORTANT

The DDC Controller is shipped with the control disabled so units do not

accidentally energize during installation. The commissioning of the rooftop

unit therefore requires the configuration of the Occupied Mode menu prior

.

Cooling

When the DDC Controller receives a call for cooling via

thermostat or zone sensor compressor 1 energizes. After the

indoor fan on delay (1-180 sec / default 10 sec) the indoor fan

energizes. The indoor fan on delay starts when the call for

cooling is initiated.

When used in local zone sensor mode of operation, the DDC

Controller satisfies the set point using all or a partial number

of stages available. When cooling demand exists, the DDC

Controller will stage up in the following order: Economizer, First

Stage Cooling, and Second Stage Cooling based on demand.

When used in local thermostat mode of operation, the DDC

Controller allows the thermostat to control the demand for

cooling. When cooling demand exists, the DDC Controller

will stage up in the following order: Economizer, First Stage

Cooling. Only two stages will be allowed to energize, so if the

economizer is active then the first stage mechanical cooling will

become second stage and second stage mechanical cooling

will not be used.

Heat

When in heating mode of operation, the DDC Controller

satisfies the set point using all or a partial number of stages

available. When heating demand exists, the DDC Controller

will utilize heat sources in the following order of priority as

available: Gas Heat and Electric.

When the heat demand requires multiple heating outputs at

the same time, a minimum staging delay of 5 seconds between

energizing and de-energizing heating outputs is necessary to

prevent the inrush current startup of multiple loads. The inter

stage is adjustable between 5 and 50 seconds.

The source of demand, like the other modes of operation, is a

result of one of either thermostat or remote sensors.

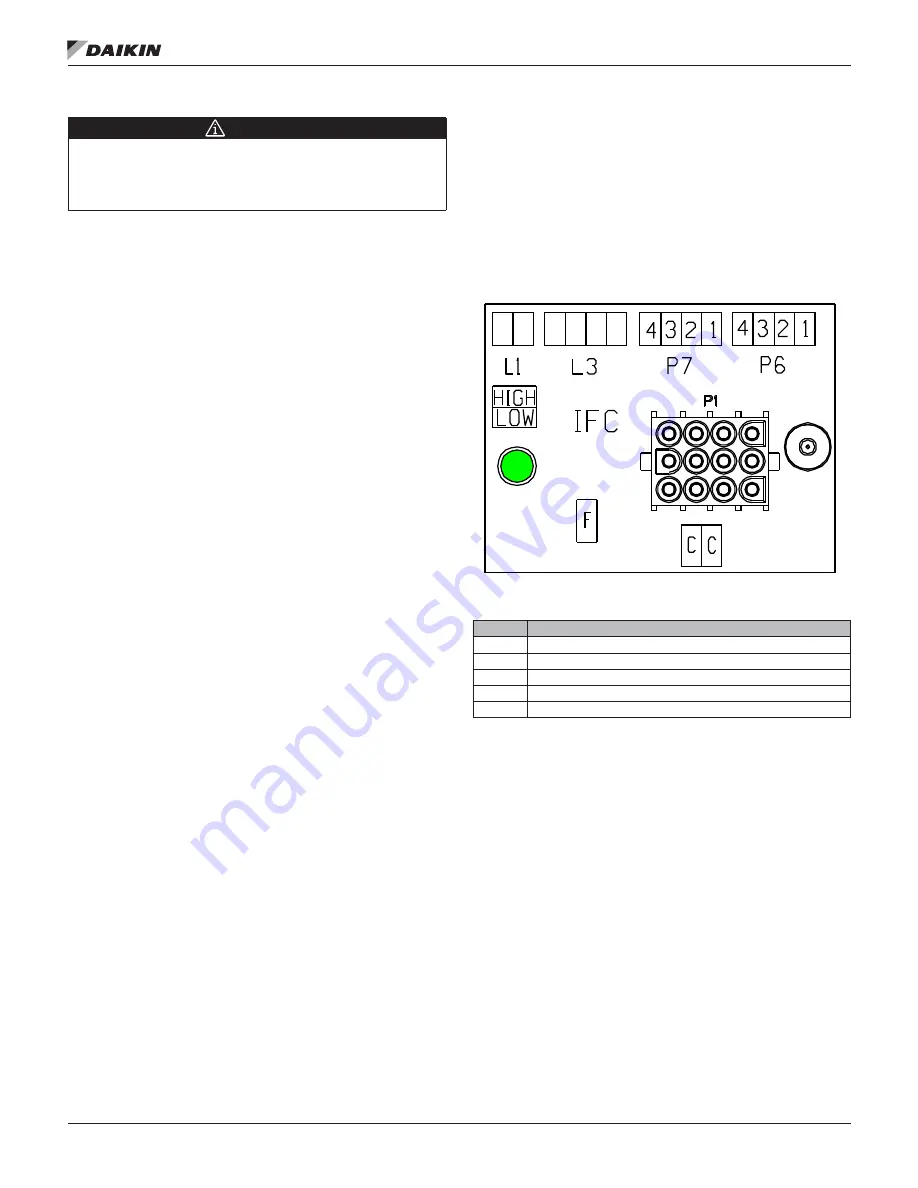

Integrated Furnace Control

The Integrated Furnace Control (IFC) is external to the DDC

Controller, and on units so equipped, controls the furnace and

gas valve operation based on signals from the DDC controller.

The IFC also provides furnace troubleshooting information via

LED flashing fault codes. When a fault condition exists, the

LED (see

) flashes the number of times indicated by

the code number, pauses, and repeats.

Figure 7: Integrated Furnace Control Status LED

Table 6: Integrated Furnace Control Fault Codes

Code

Meaning

1

Failure To Detect Or Sustain Flame

2

Pressure Switch Or Inducer Problem Detected

3

High Limit Protection Deice Open

4

Gas Valve Not Energized Or No “W” Signal

5

Flame Toll Out Switch Open

Call for Heat

After a call for heat the IFC checks to ensure the high

temperature limit and rollout switches are closed. If either

is open, the IFC responds with a fault code. If high limit and

rollout switches are closed, the IFC checks that both pressure

switches are open. If either pressure switch is closed, the

IFC will respond with a fault code and it will flash code “2”

on the LED, waiting indefinitely for both pressure switches to

open. If both pressure switches are open, the IFC proceeds

to prepurge.

LED