OM 1239

12 www.DaikinApplied.com

Dehumidification

•

Hot gas reheat with temperature control

–

Uses a combination of 2-stage thermostat and

humidistat to optimize unit capacity and for

maximum latent capacity while decreasing room

humidity levels. On a call for cooling, the fan will

energize, the pump request will energize, the

45 second flow timer will start. After the flow,

compressor minimum off, and random startup

timers are expired, the lead compressor will

start. If the room setpoint temperature is still not

satisfied, the lag compressor will be energized

as the stage 2 cooling settings. When the

room temperature conditions are satisfied, the

compressors will shut off and the fan will operate

according to its "fan only" setting when enabled

for continuous fan operation. If fan cycling is

enabled, the fan will turn off, once room setpoint

conditions are satisfied.

Available operating modes

•

Occupied

– The MicroTech III unit controller

will manage occupied and unoccupied modes

of operation. The occupancy mode can

be established by a BACnet or

L

on

W

orks

communication signal, from a room sensor

equipped with “Occupied/Unoccupied” mode

functions, or a thermostat equipped with an

“Occupied/Unoccupied” mode switch. When in

the occupied mode, the unit will be controlled to

its occupied setpoint conditions. The occupancy

state will be displayed on sensors equipped with

“Occupied/Unoccupied” mode functions and

annunciation capabilities.

•

Unoccupied

– When operating in the unoccupied

mode, the unit will be controlled to its unoccupied

setpoint conditions and the fan will cycle

according to a call for cooling, dehumidification

or heating. A simple “grounded” signal between

terminals U and C on the MicroTech III unit

controller will place the unit into the unoccupied

mode for night setback operation. The occupancy

state will be displayed on sensors equipped with

“Occupied/Unoccupied” mode functions and

annunciation capabilities.

•

Override

– A momentary (4 to 9 seconds) press

of the “Override” button on the thermostat or

room sensor during the unoccupied mode will

cause the unit to operate in the occupied mode

for two hours, for after-hours heating, cooling or

dehumidification. “OVERRIDE” will be displayed

on sensors equipped with override button and

annunciation capabilities.

•

Standby mode

– BACnet or

L

on

W

orks

units

can receive a signal from the Building Automation

System (BAS) to initiate the energy savings mode.

This mode is typically initiated by the BAS with

smart grid technologies to save energy. The savings

is driven by reducing peak electrical demand for

the building. Once initiated, the MicroTech III unit

controller will reset its effective setpoint to minimize

the stage of compressor operation. “E-SAVE” will be

displayed on sensors equipped with bypass mode

annunciation capabilities.

•

Emergency unit shutdown

– A simple grounded

signal puts the unit into the shutdown mode.

Remote shutdown is provided so that when

properly connected to a water loop controller or

remote switch, the emergency shutdown input

can be used to shut down the water source

heat pump. Compressor and fan operations are

suspended, and an a unique two external LED

status is generated.

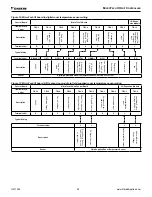

MicroTech III unit protection

The control inputs are High Pressure (HP1/HP2), Low

Pressure (LP1/LP2), Suction Line Temperature Sensor

(SLTS1/SLTS2), Condensate Overflow (COF), freeze

fault, Unoccupied (U), and Remote Shutdown (E). The

control inputs are in normal states during occupied mode.

The state of each control in occupied mode during normal

operation is as follows:

•

High pressure (HP1/HP2):

Normally closed

switch that opens on a high refrigerant pressure

condition. Control will generate a high pressure fault

and disables the compressor output on the circuit

where the switch is open. Upon a failure of the

lead compressor, it will be "fail replaced" by the lag

compressor if available.

•

Low pressure (LP1/LP2):

Normally closed switch

that opens on a low refrigerant pressure condition.

Control will generate a low pressure fault on the

circuit where the switch is open.

•

Short cycle protection & random start –

After

power cycle or deactivation of certain alarms,

or when leaving the unoccupied mode, a new

random compressor start-delay time between 300

and 360 seconds is generated. The random start

timer prevents compressors in different units from

starting simultaneously. Compressor minimum

OFF 360 sec) and compressor minimum ON (180

sec) timers prevent compressor short cycling.

•

Suction line temperature sensor (SLTS1/SLTS2)

:

The control module will monitor the SLT sensor and

if the refrigerant temperature drops below the low

temperature limit set point, the controller will go into

the low temperature fault mode.

M

ICro

t

eCh

III u

nIt

C

ontroller