OM 1239

14 www.DaikinApplied.com

•

The fault terminal (A) energizes while the unit is

in defrost mode. It will stay energized until the

temperature recovers to 36°F for standard equipment

(14.5°F for extended range). A to C will be used to

indicate an alarm signal. The previous operation of

heating or cooling determines how the low suction

temp alarm must be reset. The fan and pump remain

available for operation.

■

Cooling mode

When the suction line temperature falls below 28°F standard

equipment (28°F extended range) in cool mode the:

•

Compressor de-energizes.

•

The fan and pump remain available for operation.

•

Alarm output energizes.

•

When the suction line temperature recovers to 36°F

standard equipment (14.5°F on extended range) the

low temperature fault continues and the compressor

will be locked out.

■

Fan only mode

When the suction line temperature falls below 28°F standard

equipment (28°F extended range) in cool mode the:

•

The fan and pump remain available for operation.

•

Alarm output energizes.

The previous operation of heating or cooling determines

how the low suction temp alarm must be reset.

•

Interstaging timer –

A default value of 5 minutes

between staging of compressors, this feature

minimizes short cycling of compressors and

improves comfort.

•

Motorized water valve or pump start

– When

there is a call for cooling, dehumidification or

heating, the MicroTech III unit controller will energize

its IV/PR (H8) terminal to open the motorized water

valve or start the loop pump 45 seconds prior to

starting the compressor. The IV/ PR (H8) terminal

may be “daisy chained” between 200 units.

•

Lead compressor fail replacement

– Upon

detection of a lead compressor fault and the

lag compressor is available, the selected lead

compressor will be “failed replaced” by the lag

compressor. Lead compressor will immediately be

de-energized by ignoring the compressor minimum

ON timer. Lag compressor will energize in place of

the failed lead compressor, when the lag compressor

minimum OFF timer has expired. Reversing valve for

the lag compressor will be positioned, if necessary, 5

seconds after the lag compressor starts up.

•

Compressor protection for size 290

–

A communications module installed in the

compressor electrical box provides advanced

diagnostics, protection and communications, that

enhance compressor performance and reliability.

Fault status and LED annunciation

■

High / low pressure faults (HP/LP)

•

Normally closed high and low pressure

switches will protect both circuits of the water

source heat pump from excessively high or low

refrigerant pressure conditions. The MicroTech

III monitors these switches individually. If either

compressor is running and the high pressure

switch for that circuit opens that compressor

will shutdown immediately. The MicroTech III

will enter "compressor faili replace" mode which

will allow the other circuit to operate normally

while it is able. If the LP switch remains open for

either circuit for the Low Pressure Time Delay

(default is 30 seconds) that compressor will

shutdown immediately. The MicroTech III will enter

"compressor faili replace" mode which will allow

the other circuit to operate normally while it is

able. If both compressors are off on a high or low

pressure fault the MicroTech III will go into Fault

mode and neither compressor is available.

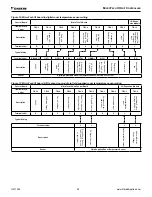

MicroTech III LED Status – High/Low Pressure Faults

Pressure

Yellow

Green

Red

HP

Off

Off

Flash

LP

Off

Off

Solid

Note: Circuit 2 faults are annunciated on the I/O expan-

sion module.

See Table 9 on page

19.

When the unit is in high or low pressure fault modes the

following occurs:

•

The failed compressor de-energizes.

•

The fault terminal (A) energizes (fault). A to R will

be used to indicate an alarm signal.

■

Low suction temperature fault heating

•

The control will attempt to recover either circuit from

a low suction temperature condition by defrosting

the water heat exchanger(s) (coaxial coil). See

"Defrost process operation:" on page

14

for

details.

M

ICro

t

eCh

III u

nIt

C

ontroller