15/77

Operation Manual

D

–EOMWC00A07-16_02EN

X7

Motor Protection

PTC Thermistor

n/a

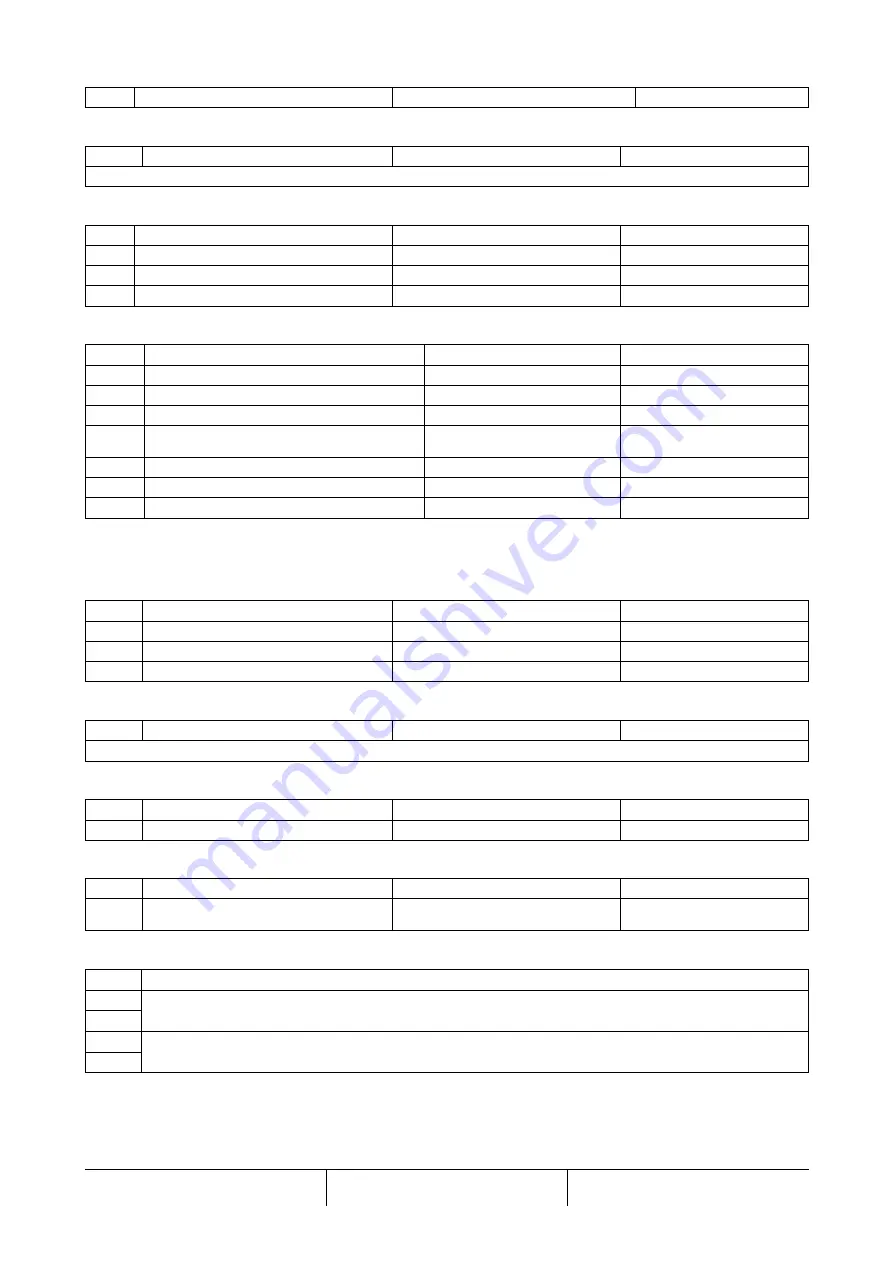

6.2.2

Analog Outputs

#

Description

Output Signal

Range

Not Needed

6.2.3

Digital Inputs

#

Description

Signal Off

Signal On

X6

Starter Fault

Fault

No fault

X8

Circuit Switch

Circuit Off

Circuit On

DI1

High Pressure Switch

Fault

No fault

6.2.4

Digital Outputs

#

Description

Output Off

Output On

DO1

Start Compressor

Compressor Off

Compressor On

DO2

Circuit Alarm

Circuit Alarm Off

Circuit Alarm On

DO3

Load #2 Circuit

Load 2 Circuit Off

Load 2 Circuit On

DO4

Unload #2 Circuit / Liquid Injection

Unload 2 Circuit Off /

Liquid Injection Off

Unload 2 Circuit On /

Liquid Injection On

DO5

Load #1 Circuit

Load 1 Circuit Off

Load 1 Circuit On

DO6

Unload #1 Circuit

Unload 1 Circuit Off

Unload 1 Circuit On

X5

Turbo Slide

Turbo Slide Off

Turbo Slide On

6.3

I/O EXV Circuit #1 to #3

6.3.1

Analog Inputs

#

Description

Signal Source

Expected Range

X1

Evaporator Leaving Water Temp (*)

NTC Thermister 10K@25°C)

-50°C

– 120°C

X2

Suction Temperature

NTC Thermister 10K@25°C)

-50°C

– 120°C

X3

6.3.2

Analog Outputs

#

Description

Output Signal

Range

Not Needed

6.3.3

Digital Inputs

#

Description

Signal Off

Signal On

DI1

Evaporator Flow Switch (Circuit)

No Flow

Flow

6.3.4

Digital Outputs

#

Description

Output Off

Output On

DO1

Liquid Line Solenoid Valve

Liquid Line Solenoid Valve Off

Liquid Line Solenoid Valve

On

6.3.5

Stepper Motor Output

#

Description

M1+

EXV Stepper Coil 1

M1-

M2+

EXV Stepper Coil 2

M2-