53/77

Operation Manual

D

–EOMWC00A07-16_02EN

10.8.9

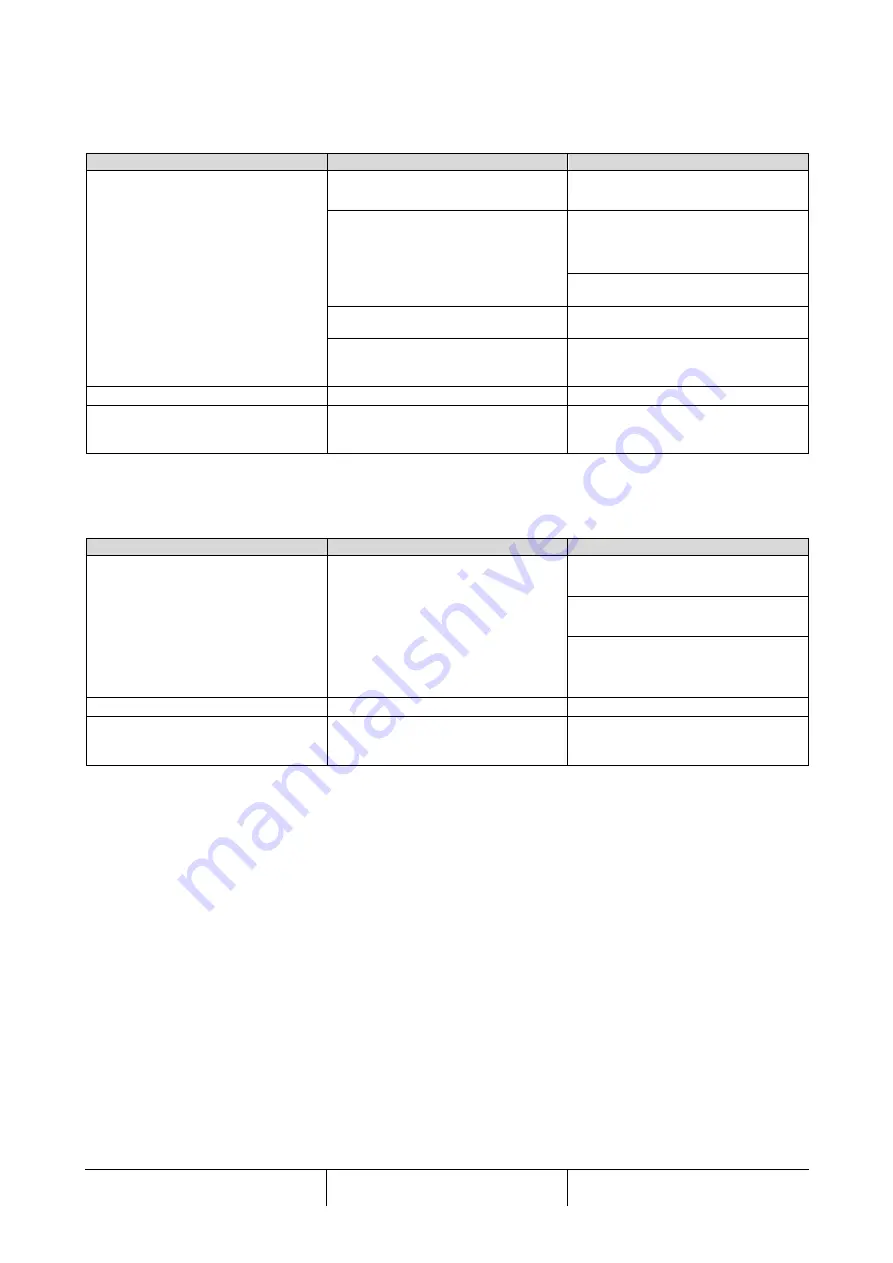

No Pressure Change After Start

This alarm indicates that the compressor is not able to start or to create a certain minimum variation of the evaporating

or condensing pressures after start.

Symptom

Cause

Solution

Circuit status is Off.

The circuit is stopped.

Bell icon is moving on controller’s

display.

String in the alarm list:

Cx OffNoPressChgStart

String in the alarm log:

Cx OffNoPressChgStart

String in the alarm snapshot

Cx OffNoPressChgStart

Compressor cannot start.

Check if the start signal is properly

connected to the inverter.

Compressor is turning in wrong

direction.

Check correct phases sequence to

the compressor (L1, L2, L3)

according to the electrical scheme.

Inverter is not properly programmed

with the right direction of rotation.

Refrigerant circuit is empty of

refrigerant.

Check circuit pressure and presence

of refrigerant.

Not proper operation of evaporating

or condensing pressure transducers.

Check proper operation of

evaporating or condensing pressure

transducers.

Reset

Notes

Local HMI

Network

Auto

10.8.10

No Pressure At Startup

This alarm is used to indicate a condition where the pressure at the evaporator or at the condenser is lower than 35kPa,

so the circuit is potentially empty of refrigerant.

Symptom

Cause

Solution

Circuit status is Off.

The compressor does not start

Bell icon is moving on controller’s

display. String in the alarm list:

Cx OffNoPressAtStart

String in the alarm log:

Cx OffNoPressAtStart

String in the alarm snapshot

Cx OffNoPressAtStart

Evaporator or condenser pressure

are below 35kPa

Check transducers calibration with an

appropriate gauge.

Check transducers cabling and

readout.

Check refrigerant charge and set it to

the proper value.

Reset

Notes

Local HMI

Network

Auto