61/77

Operation Manual

D

–EOMWC00A07-16_02EN

10.10.2

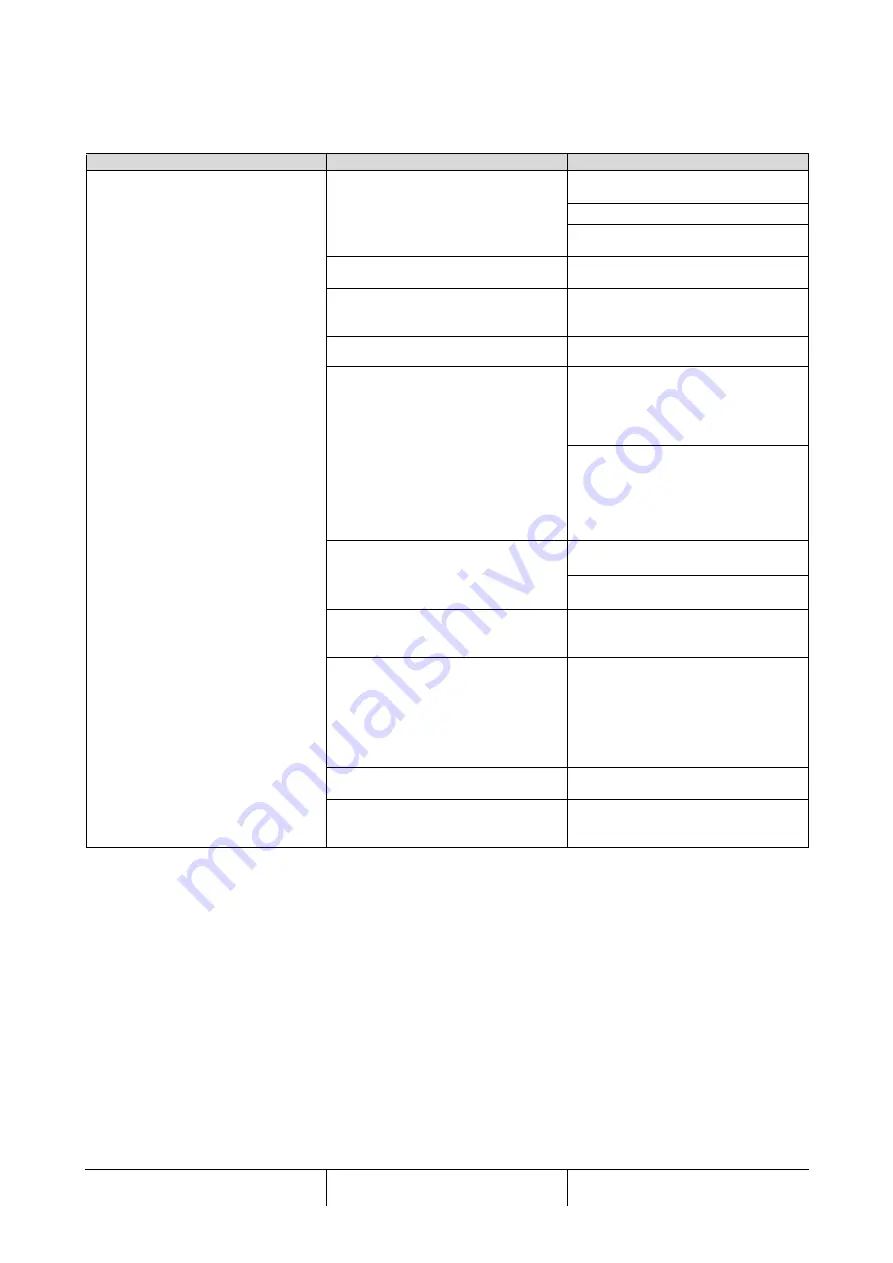

High Condenser Pressure

– Hold/Unload

These events are generated to indicate a temporary condition with the condensing pressure above the hold and unload

limits.

Symptom

Cause

Solution

Circuit status is

Run: High Cond Press

The compressor does not load

anymore or even unload.

String in the Event log:

CxCmp1 HiCondPrHold

CxCmp1 HiCondPrUnld

One or more condenser fans do not

operate properly (Condenserless

units).

Check if fans protections have been

activated.

Check that the fans can turn freely.

Check that there is not any obstacle

to the free ejection of the air blown.

Condenser pump may not be

operating correctly.

Check if the pump can run and give

the required water flow.

Dirty or partially blocked condenser

coil (Condenserless units).

Remove any obstacle;

Clean the condenser coil using soft

brush and blower.

Dirty condenser heat exchanger.

Clean the condenser heat exchanger.

Inlet air temperature of the condenser

is too high (Condenserless units).

The air temperature measured at the

inlet of the condenser may not

exceed the limit indicated in the

operational range (working envelope)

of the chiller.

Check the location where the unit is

installed and check that there are no

any short circuit of the hot-air blown

from the fans of the same unit, or

even from fans of next chillers

(Check IOM for proper installation).

Entering water temperature at

condenser is too high.

Check the cooling tower operation

and settings.

Check the three way valve operation

and settings.

One or more condenser fan turning in

wrong direction (Condenserless

units).

Check for correct phases sequence

(L1, L2, L3) in the electrical

connection of the fans.

Excessive charge of

refrigerant into the unit.

Check liquid sub-cooling and suction

super-heat to control indirectly the

correct charge of refrigerant.

If necessary recover all the

refrigerant to weight the entire charge

and to control if the value is in line

with kg indication on unit label.

Condensing pressure transducer

could not operate properly.

Check for proper operation of the high

pressure sensor.

Wrong unit configuration.

Check that the unit has been

configured for high condenser

temperature applications.