8

Residual risks

Despite having implemented and adopted all the safety measures indicated by applicable regulations,

some residual risks remain. In particular, in some operations of replacement, adjustment and tooling max-

imum attention is always required in order to work in the best possible conditions.

List of operations with residual risks

Risks for qualified personnel (electrician and mechanic)

-

Handling - during unloading and handling it is necessary to pay attention to all the steps listed in this manual regarding the points

of reference

-

Installation - during installation it is necessary to pay attention to all the steps listed in this manual regarding the points of reference

The installer must ensure the static and dynamic stability of the machine's site of installation.

-

Maintenance - during maintenance it is necessary to pay attention to all the steps listed in this manual, and in particular to high

temperatures that may be present in the heat transfer fluid lines to/from the unit.

-

Cleaning - the machine must be cleaned only when it is switched off, by turning off the switch installed by the electrician and the

switch located on the unit itself. The key for interrupting the power supply must be kept by the operator until the end of the clean-

ing operations. Internal cleaning of the machine must be carried out using the protections required by current regulations. While

the inside of the machine does not contain particular hazards, it is necessary to pay the utmost attention so that accidents do not

occur during cleaning. The heat exchange coils that have a potentially sharp finned pack must be cleaned using protective glasses

and gloves suitable for handling metals.

During adjustment, maintenance and cleaning there are residual risks of variable entity. Being operations

that must be performed with guards disabled, it is necessary to pay particular attention in order to avoid

damage to persons and things.

Always pay close attention when performing the operations specified above.

Remember that these operations must always be performed by authorised personnel.

All work must be completed in accordance with the legal provisions relating to work safety.

Remember that the unit in question is an integral part of a larger system that includes other components,

depending on the final characteristics of realisation and the mode of use. Therefore in the end it is the re-

sponsibility of the user and assembler to assess the residual risks and their respective preventive measures.

For more information about the possible risks, please refer to the RAD (Risk Assessment Docu-

ment) available from the manufacturer.

Summary of Contents for Modular Plate

Page 15: ...15 Notes...

Page 28: ...28 Notes...

Page 33: ...33 VDI 6022 6...

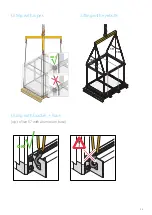

Page 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

Page 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Page 44: ...44 6 7 NO OK...

Page 45: ...45 H2O SOAP 8...

Page 46: ...46 9...

Page 47: ...47 Notes...

Page 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...