29

2A

All installation, assembly, electrical connections to the mains and extraordinary maintenance

must be performed

only by qualified personnel authorised by the Retailer or Manufac-

turer

, in compliance with the regulations in force in the country the equipment is to be used

and the standards on the systems and safety in the workplace.

During installation, the area must be free from people

and objects not used for the assembly.

Before starting, make sure you have all the necessary

equipment.

Use only equipment that is in good condition and un-

damaged.

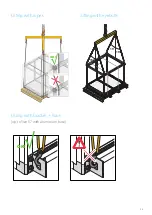

There are two different types of hook, refer to the assembly instructions for the one in your possession.

Any movement carried out after unpacking must be done with the doors closed.

Do not move the units by pulling on the doors, if present, the uprights or other protruding parts that are

not an integral part of the structure.

Do not step on the units!

Before proceeding with the installation of the machine, it is necessary to prepare the power supplies and

utilities necessary for the correct operation of the system and, if required, consulting in advance with the

Manufacturer's Technical Office.

The machine does not require special environmental conditions for its operation. For a correct instal-

lation it is sufficient to prepare a level support surface, indispensable for the correct operation of the

machine and to guarantee the regular opening of the inspection doors.

The altitude of the installation room must be less than 1,000 meters above sea level (at higher altitudes

the electric motors deliver powers lower than the nominal ones).

The installation in the workplace must be done in such a way that the machine and its equipment are

accessible to allow it to start, stop and carry out maintenance work on the machine.

For the choice of location, in general, care must be taken that an operator can move around the ma-

chine without hindrance. The minimum distance to the nearest wall must in any case be at least equal

to the width of the machine.

Where there are no means of transport to move the machine, its positioning must take into account the

free space required for any repairs. It is of course necessary to plan enough space for regular operation,

as well as for machine maintenance, including all the space for any peripheral equipment.

To operate the machine requires:

- Electrical connections;

- Water connection;

- Air duct connection.

Installation

6

Summary of Contents for Modular Rotary

Page 15: ...15 Notes...

Page 28: ...28 Notes...

Page 33: ...33 VDI 6022 6...

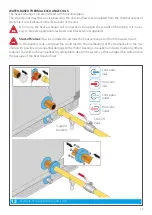

Page 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

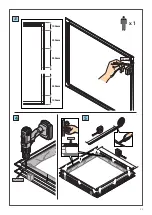

Page 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Page 44: ...44 6 7 NO OK...

Page 45: ...45 H2O SOAP 8...

Page 46: ...46 9...

Page 47: ...47 Notes...

Page 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...