IOM 1264-1 • NAVIGATOR

®

MODEL WWV CHILLERS

20 www.DaikinApplied.com

C

onTroller

o

peraTIon

C

onTroller

o

peraTIon

Operator Responsibilities

It is important that the operator become familiar with the

equipment and the system before attempting operation. During

the initial startup of the chiller, the Daikin Applied service

technician will be available to answer any questions and

instruct the proper operating procedures. It is recommended

that the operator maintain an operating log for each individual

chiller unit. In addition, a separate maintenance log should be

kept of the periodic maintenance and servicing activities.

Operator Schools

Training courses for Navigator

®

Water-cooled Screw

Maintenance and Operation are held throughout the year at the

Daikin Learning Institute in Verona, Virginia. The class includes

instruction on basic refrigeration, MicroTech

®

III controllers,

enhancing chiller efficiency and reliability, MicroTech

®

III

troubleshooting, system components, and other related

subjects. For more information, refer to the back cover of this

document for Training contact information.

MicroTech

®

III Unit Controller

Inputs/Output

s

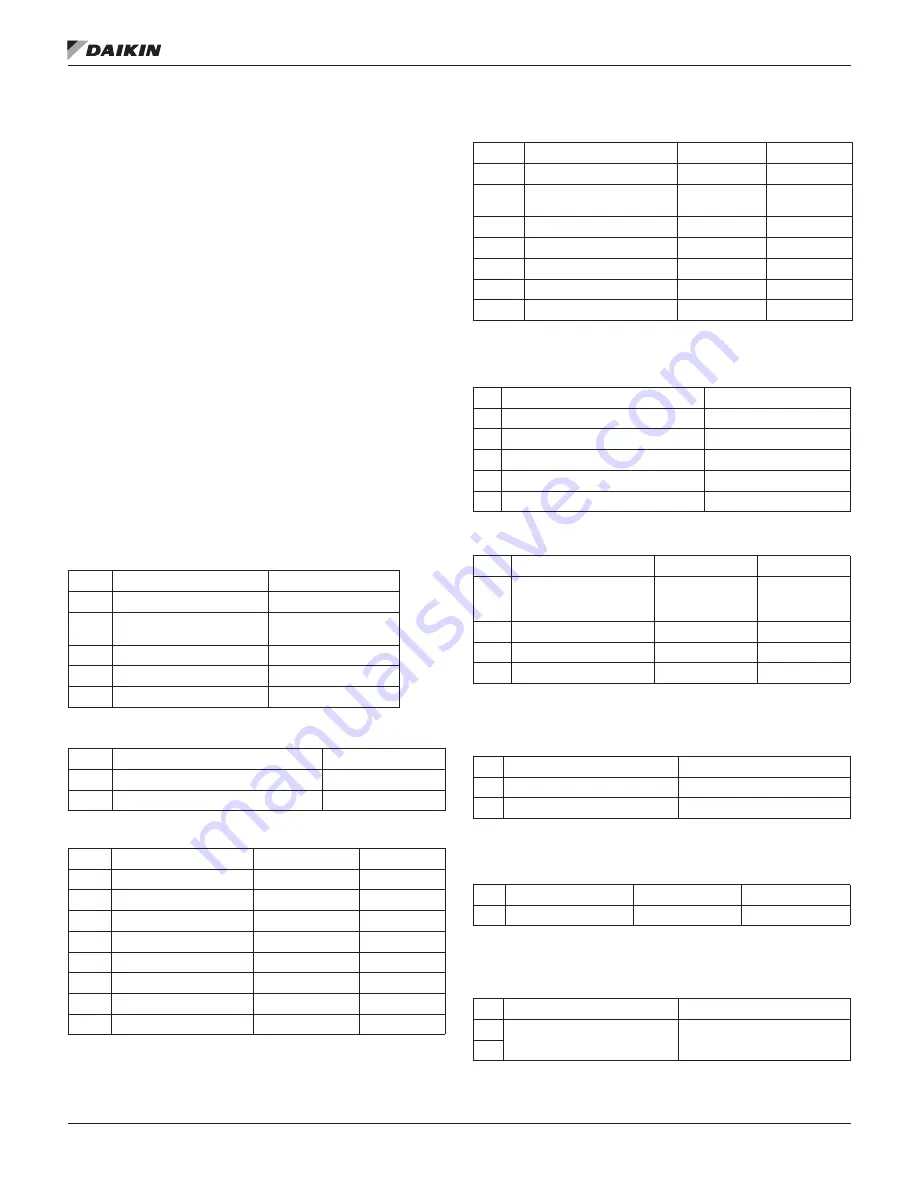

Table 9: Analog Inputs

#

Description

Signal Source

AI1

Evap Entering Water Temp NTC 10KThermister

AI2

Condenser Entering Water

Temp

NTC 10KThermister

X3

Demand Limit

4-20 mA Current

X4

LWT Reset

4-20 mA Current

X6

Evap Leaving Water Temp NTC 10KThermister

Table 10: Analog Outputs

#

Description

Output Signal

X5

Cooling Tower VFD Speed

0-10VDC

X7

Cooling Tower Bypass Valve Position 0-10VDC

Table 11: Digital Inputs

#

Description

Signal Off

Signal On

DI1

Unit Ground Fault Relay Fault

No Fault

DI2

Evaporator Flow Switch

No Flow

Flow

DI4

Remote Switch

Unit disable

Unit enable

DI5

Unit Switch

Unit disable

Unit enable

DI6

External Alarm

Unit disable

Unit enable

X1

Emergency Stop

Unit off

Unit enable

X2

Mode Switch

Cool Mode

Ice Mode

X8

Condenser Flow Switch

No Flow

Flow

Table 12: Digital Outputs

#

Description

Output OFF

Output ON

DO1

Evaporator Water Pump 1 Pump Off

Pump On

DO2

Alarm Relay

Alarm not

Active

Alarm Active

DO3

Condenser Water Pump 1 Pump Off

Pump On

DO5

Cooling Tower Fan 1

Off

On

DO6

Cooling Tower Fan 2

Off

On

DO9

Evaporator Water Pump 2 Pump Off

Pump On

DO10

Condenser Water Pump 2 Pump Off

Pump On

CC1 Module

Table 13: Analog Inputs

#

Description

Signal Source

X1 Discharge Temperature Circuit 1

NTC 10k Thermister

X2 Evaporator Pressure Circuit 1

Ratiometric 0.5-4.5 Vdc

X3 Oil Pressure Circuit 1

Ratiometric 0.5-4.5 Vdc

X4 Condenser Pressure Circuit 1

Ratiometric 0.5-4.5 Vdc

X6 Condenser Leaving Water Temp

NTC 10k Thermister

Table 14: Digital Outputs

#

Description

Output Off

Output On

DO1 Oil Return Solenoid

Valve & Jet Pump

Solenoid Valve Circuit 1

Solenoid Closed Solenoid Open

DO3 VVR SV 1 Circuit 1

Solenoid Closed Solenoid Open

DO4 VVR SV 2 Circuit 1

Solenoid Closed Solenoid Open

DO5 VVR SV 3 Circuit 1

Solenoid Closed Solenoid Open

Evaporator EXV1 Module

Table 15: Analog Inputs

#

Description

Signal Source

X2 Suction Temperature Circuit 1

NTC 10k Thermister

X3 Liquid Temperature Circuit 1

NTC 10k Thermister

RapidRestore

®

Module

Table 16: Digital Inputs

#

Description

Signal Off

Signal On

DI1 RapidRestore Unlock Lock Out Option

Unlock Option

Compressor VFD1 Module

Table 17: Analog Inputs

#

Description

Signal Source

50

Circuit 1 Motor Temperature

PTC Thermister

54

Summary of Contents for Navigator WWV

Page 4: ......