IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

20 www.DaikinApplied.com

Installation and Application Considerations

Flow Switch

A flow switch must be included in the chilled water system

to prove that there is adequate water flow to the evaporator

before the unit can start, or to shut down the unit if water flow

is interrupted. A factory-included thermal dispersion flow switch

will be installed on packaged models. On remote evaporator

models, the flow switch may be separately field-provided, or

optionally shipped loose for field installation.

Installation should be per manufacturer’s instructions included

with the switch. Flow switches should be calibrated to shut off

the unit when operated below the minimum flow rate for the

unit. Flow switch installation and calibration is further discussed

.

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the application of

air-cooled water chillers in areas experiencing below freezing

temperatures. To protect against freeze-up, insulation and an

electric immersion heater are furnished with the evaporator.

This helps protect the evaporator down to -20°F (-29°C)

ambient air temperature. Although the evaporator is equipped

with freeze protection, it does not protect water piping external

to the unit or the evaporator itself if there is a power failure or

heater burnout, or if the chiller is unable to control the chilled

water pumps. Use one of the following recommendations for

additional protection:

• If the unit will not be operated during the winter, drain

evaporator and chilled water piping and flush with

glycol. Drain and vent connections are provided on the

evaporator for this purpose.

• Add a year-round glycol solution to the chilled water

system to provide freeze protection. Freeze point should

be approximately 10°F (5.6°C) below minimum design

ambient temperature or 10°F (5.6°C) below the lowest

design leaving water temperature, whichever is lower.

The use of glycol antifreeze is generally considered

the safest protection against freeze-up; however, it will

reduce the performance of the unit, depending on the

concentration. Take this into consideration during initial

system design and selection. On glycol applications, a

minimum fluid concentration should be based on Burst

Protection limits.

•

The field addition of thermostatically controlled heat

tracing and insulation to exposed piping, dependent on

power availability.

• Continuous circulation of water through the chilled water

piping and evaporator, with ability to control temperature

within chiller safety limits. (Dependent on power

availability).

• The evaporator immersion heater is factory-wired to the

115-volt circuit in the control box. This power can be

supplied from a separate source, or it can be supplied

from the control circuit. Operation of the heater cable

is automatic through the fluid sensing thermostat that

energizes the evaporator heater cable for protection

against freeze-up. Unless the evaporator is drained in

the winter, the disconnect switch to the evaporator heater

must be closed. Conversely, do not apply heat to the

evaporator if it is drained.

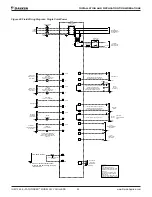

Chilled Water Pump

It is important that the chilled water pumps be wired to, and

controlled by, the chiller’s microprocessor. The chiller controller

has the capability to selectively send the signal to a pump

relay (by others) to start pump A or B or automatically alternate

pump selection and also has standby operation capability.

The controller will energize the pump whenever at least one

circuit on the chiller is enabled to run, whether there is a

call for cooling or not. This helps ensure proper unit startup

sequence. To help prevent evaporator freeze-up, the pump

will also be turned on when the water temperature is equal to

or goes below the Freeze Set Point for at least three seconds.

Connection points are shown in the Field Wiring Diagrams on

.

CAUTION

Adding glycol or draining the system is the recommended

method of freeze protection. If the chiller does not have

the ability to control the pumps and the water system is

not drained in temperatures below freezing, catastrophic

evaporator failure may occur.

Failure to allow pump control by the chiller may cause the

following problems:

1. If any device other than the chiller attempts to start the

chiller without first starting the pump, the chiller will lock

out on the No Flow alarm and require manual reset.

2. If the evaporator water temperature drops below the

“Freeze Set Point” the chiller will attempt to start the

water pumps to avoid evaporator freeze. If the chiller

does not have the ability to start the pumps, the chiller

will alarm

due to lack of water flow.

3. If the chiller does not have the ability to control the

pumps and the water system is not to be drained in

temperatures below freezing, the chiller may be subject

to catastrophic evaporator failure due to freezing. The

freeze rating of the evaporator is based on the immersion

heater and pump operation. The immersion heater itself

may not be able to properly protect the evaporator from

freezing without circulation of water.

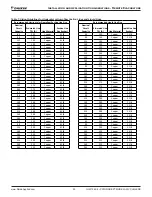

Variable Speed Pumping

Reducing evaporator flow in proportion to load can reduce

system power consumption. Daikin Applied chillers are

designed for variable water flow duty provided that the rate of

change is less than ten percent of the design flow per minute,

and the minimum and maximum flow rates for the evaporator,

beginning on

, are not exceeded. If flow drops

below the minimum allowable, large reductions in heat transfer

can occur. If the flow exceeds the maximum rate, excessive

pressure drop and tube erosion can occur. For example, if the

maximum design flow is 200 gpm and it will be reduced to a

flow of 140 gpm, the change in flow is 60 gpm. Ten percent of