IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

22 www.DaikinApplied.com

Installation and Application Considerations

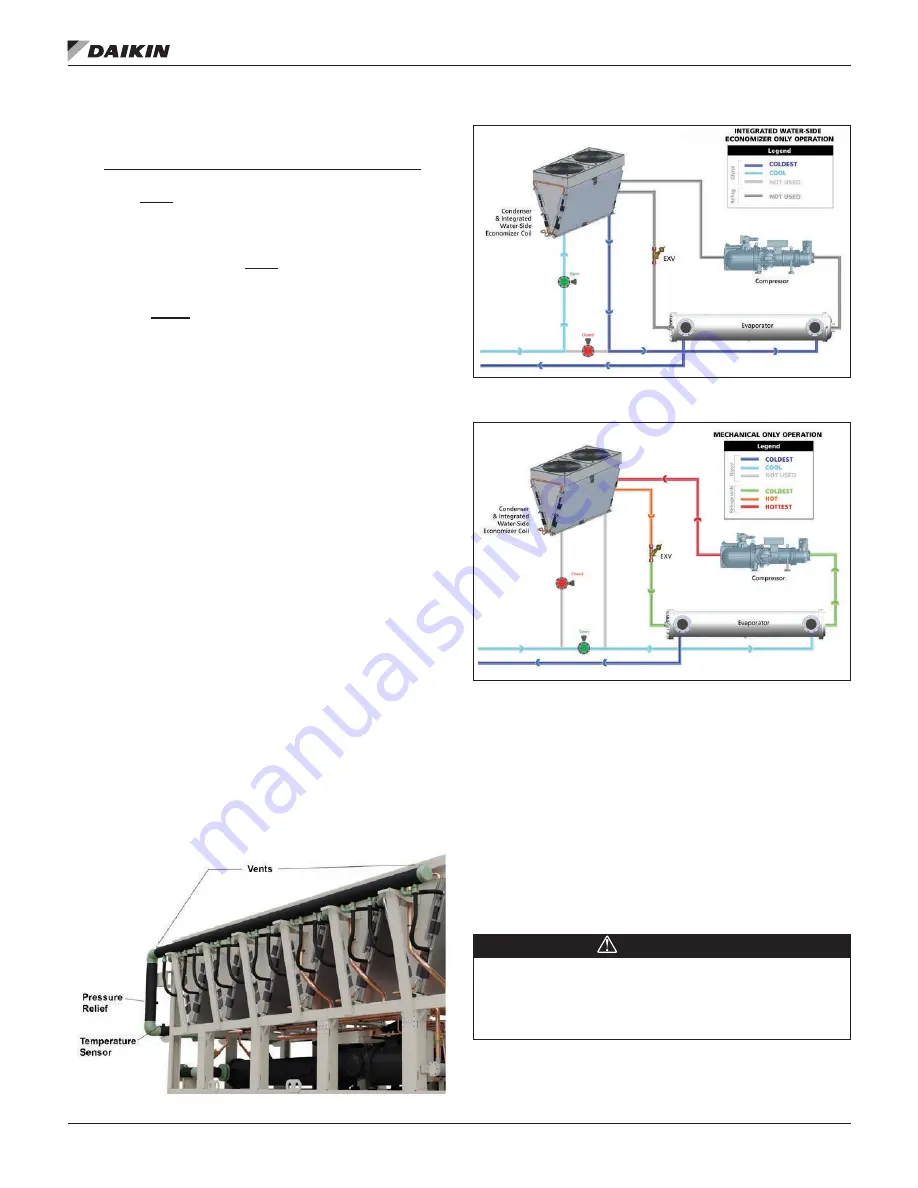

Waterside Economizer Operating

Guidelines

1 .

Fluid used in IWSE systems must contain glycol.

The system glycol percentage must be high enough to

avoid

burst

conditions at the lowest possible ambient

temperature of the installed location, regardless of

whether the unit is operating or turned off at that

minimum temperature. The chiller fluid loop is required

to be protected against

burst

conditions at least 5°F

below minimum operating and non-operating ambient

temperatures. It is recommended to protect the system

against

freeze

conditions 5°F below minimum operating

and non-operating ambient temperatures. Failure to

ensure adequate glycol freeze protection may result in

damage of the water-side economizer coils and coolant

leakage from the system.

2. If the chiller is hydraulically isolated, some method of

pressure relief must be added to the chiller side fluid

loop such as a relief valve or expansion tank; see

for connection port. Daikin supplied relief valve kit

provides relief valve with ½” female NPT connection and

allows for customer to pipe to blowdown tank or other

receptacle as may be required by local building codes.

The system must not have quick-acting valves or other

sources of surge pressure in the fluid loop.

3.

Maximum flow rates must be observed to protect IWSE

coils and piping; see

Pressure Drop Data on page 42.

4. A strainer for the glycol system must meet the

Inlet Strainer Guidelines on page 18.

5. Inhibitors for steel, copper, brass, and aluminum must

be included for all closed water loop systems. Some

glycols include inhibitors and should be considered when

commissioning the water system. Also, all chemicals and

additives must be compatible with polypropylene pipe.

6. The glycol system should include a biocide to protect the

system against biological growth. The biocide should be

non-ionic, non-foaming, and non-oxidizing.

7. Water system maximum allowable chlorides content is

25 ppm to prevent corrosion of aluminum IWSE coils.

Figure 43: Connection Ports on IWSE Piping

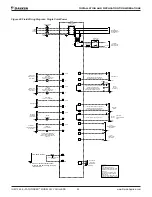

Figure 44: Integrated Waterside Economizer Operation

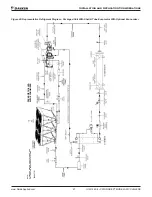

Figure 45: Mechanical Cooling Operation Only

Electrical Connections

Pathfinder

®

units can be ordered with either standard multi-

point power or optional single point power connections and

with various disconnect and circuit breaker options. Power

wiring connections to the chiller may be done with either

copper or aluminum selected conductors, provided they fit

the chiller lugs. All wiring must be done in accordance with

applicable local and national codes, including NECA/AA

10402012, Standard for Installing Aluminum Building Wire and

Cable (ANSI). Wiring within the unit is sized in accordance with

the NEC

®

. Refer to the unit nameplate and the unit selection

report for the correct electrical ratings.

DANGER

Qualified and licensed electricians must perform wiring.

Disconnect, lockout, and tag all electrical power sources to

the unit before servicing the compressor and/or removing

refrigerant. An electrical shock hazard exists that can cause

severe injury or death.