IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

34 www.DaikinApplied.com

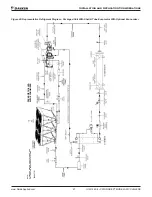

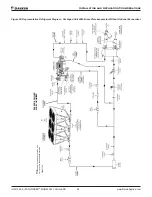

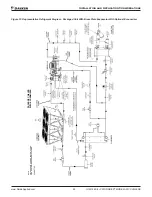

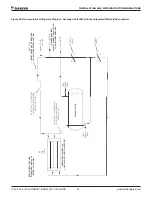

Installation and Application Considerations - Remote Evaporators

Piping Layout

shows the piping layout for one of the two refrigerant

circuits for AWV units with a remote evaporator with and

without the optional economizer circuit. The outdoor unit, the

evaporator, and a kit of refrigerant components are shipped

as separate pieces for field mounting, wiring, and piping. The

suction shutoff valve is standard on remote evaporator units.

All components between the “Field Connection Points” should

be located as close to the evaporator as possible.

Note:

Field insulation of the suction lines and the liquid line on

circuits with economizers is required. The outdoor unit will have

a refrigerant charge equal to that of a packaged unit pumped

down into the condenser. Any additional charge of refrigerant

and oil required by the field piping is supplied by the customer.

The location and size of the refrigerant connections are shown

on dimensional drawings available from a Daikin Applied sales

representative.

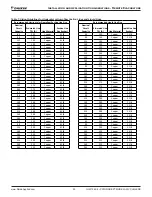

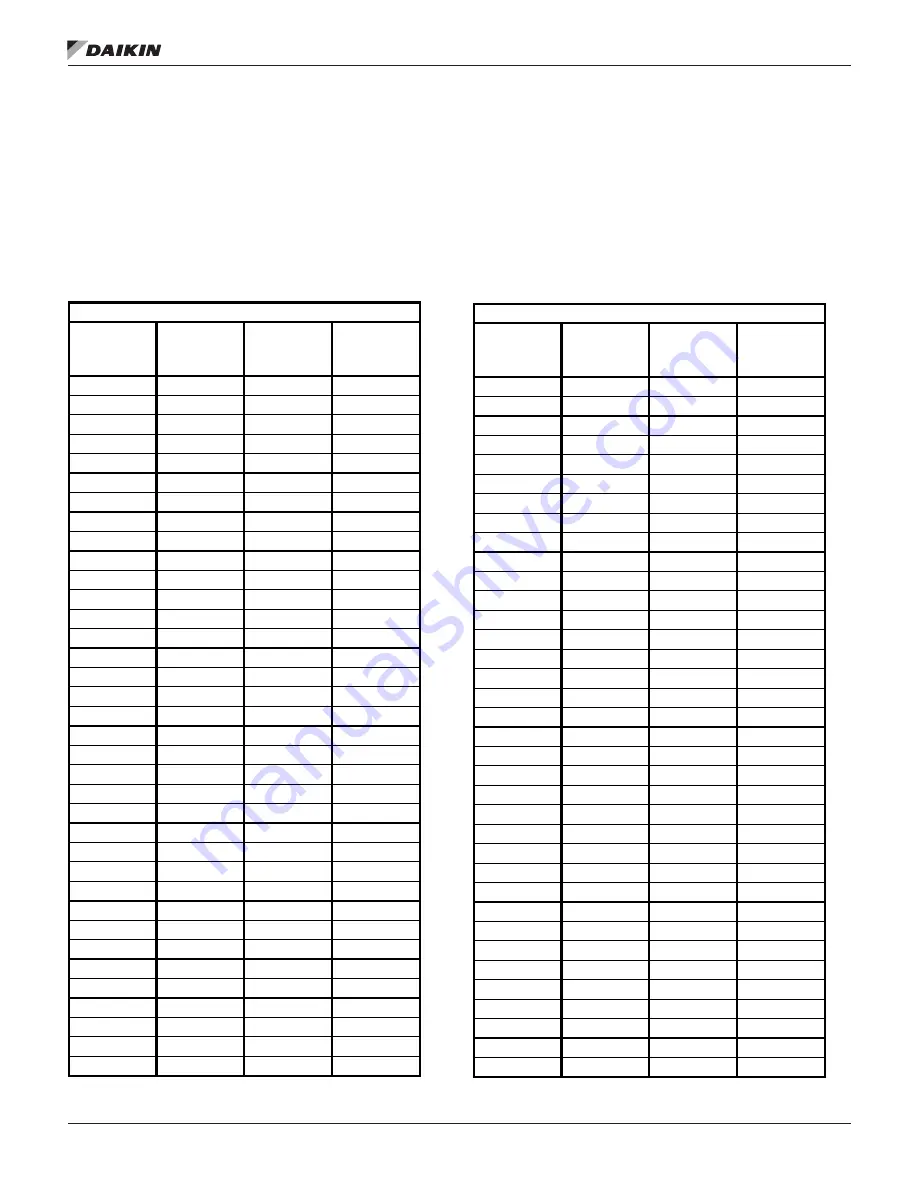

Table 6:

Sizing Guidelines for Horizontal or Downflow Suction Lines and Liquid Lines

Recommended Horizontal or Downflow Suction Line Size

Nominal

Circuit

Capacity

Estimated Line

TEL (ft)

Line Material

Suction Line

Size (Inches)

65

50

Copper

3 5/8

90

50

Copper

3 5/8

115

50

Copper

3 5/8

140

50

Copper

4 1/8

165

50

Copper

4 1/8

190

50

Copper

4 1/8

215

50

Copper

5 1/8

240

50

Copper

5 1/8

265

50

Copper

5 1/8

65

75

Copper

3 5/8

90

75

Copper

3 5/8

115

75

Copper

4 1/8

140

75

Copper

4 1/8

165

75

Copper

5 1/8

190

75

Copper

5 1/8

215

75

Copper

5 1/8

240

75

Copper

5 1/8

265

75

Copper

5 1/8

65

100

Copper

3 5/8

90

100

Copper

3 5/8

115

100

Copper

4 1/8

140

100

Copper

5 1/8

165

100

Copper

5 1/8

190

100

Copper

5 1/8

215

100

Copper

5 1/8

240

100

Copper

6 1/8

265

100

Copper

6 1/8

65

125

Copper

3 5/8

90

125

Copper

4 1/8

115

125

Copper

4 1/8

140

125

Copper

5 1/8

165

125

Copper

5 1/8

190

125

Copper

5 1/8

215

125

Copper

6 1/8

240

125

Copper

6 1/8

265

125

Copper

6 1/8

Recommended Liquid Line Size

Nominal

Circuit

Capacity

Estimated Line

TEL (ft)

Line Material

Liquid Line Size

(Inches)

65

50

Copper

1 5/8

90

50

Copper

1 5/8

115

50

Copper

1 5/8

140

50

Copper

1 5/8

165

50

Copper

2 1/8

190

50

Copper

2 1/8

215

50

Copper

2 1/8

240

50

Copper

2 1/8

265

50

Copper

2 1/8

65

75

Copper

1 5/8

90

75

Copper

1 5/8

115

75

Copper

2 1/8

140

75

Copper

2 1/8

165

75

Copper

2 1/8

190

75

Copper

2 1/8

215

75

Copper

2 1/8

240

75

Copper

2 1/8

265

75

Copper

2 5/8

65

100

Copper

1 5/8

90

100

Copper

1 5/8

115

100

Copper

2 1/8

140

100

Copper

2 1/8

165

100

Copper

2 1/8

190

100

Copper

2 1/8

215

100

Copper

2 5/8

240

100

Copper

2 5/8

265

100

Copper

2 5/8

65

125

Copper

1 5/8

90

125

Copper

1 5/8

115

125

Copper

2 1/8

140

125

Copper

2 1/8

165

125

Copper

2 1/8

190

125

Copper

2 5/8

215

125

Copper

2 5/8

240

125

Copper

2 5/8

265

125

Copper

2 5/8