Installation and Application Considerations - Remote Evaporators

www.DaikinApplied.com 37

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

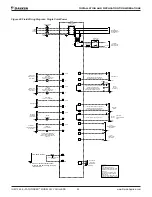

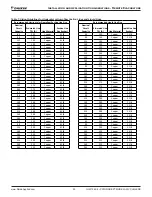

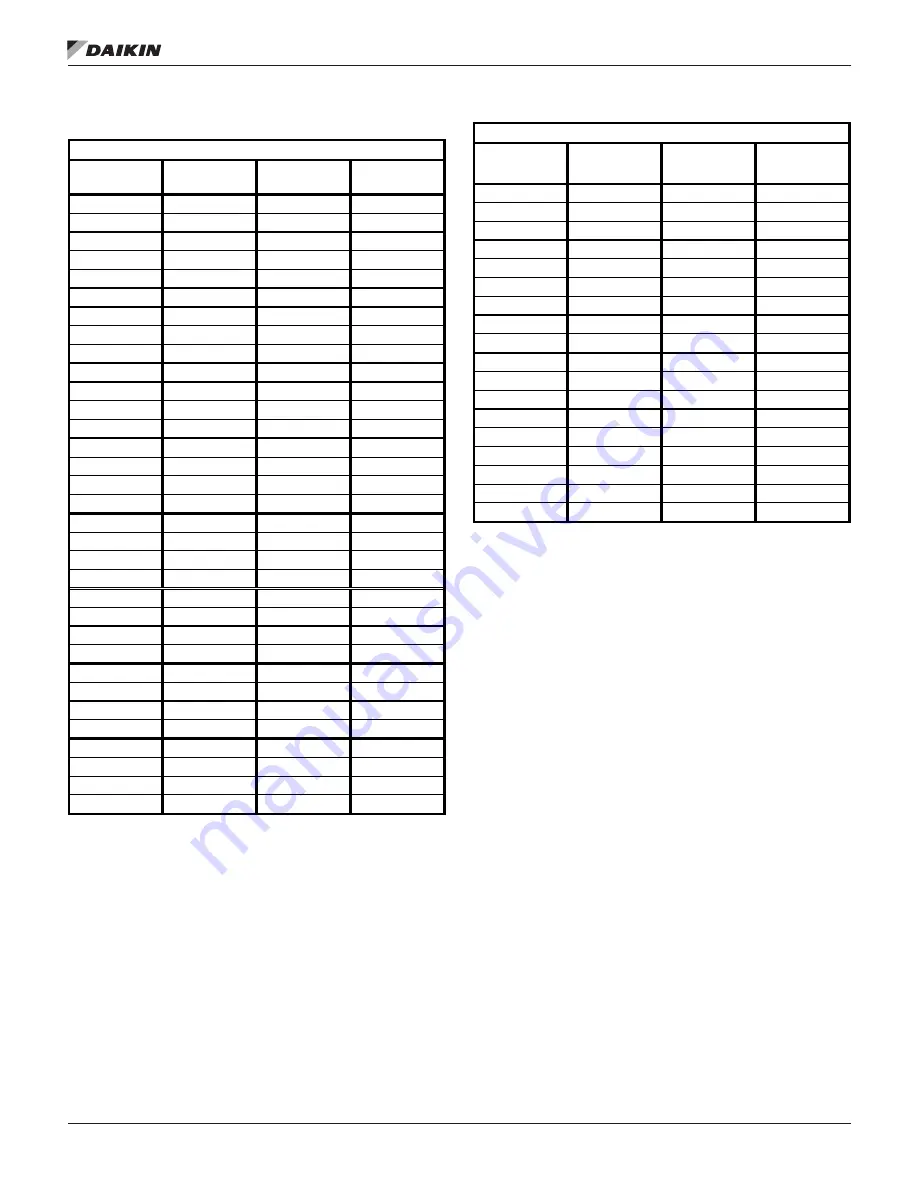

Table 9: Alternate Sizing Guidelines for Horizontal or

Downflow Suction Lines - Steel

NOTE: FOR STEEL LINES ONLY

For use in horizontal and down flow applications only where

the evaporator is at or below the chiller elevation.

Recommend schedule 40 steel pipe.

Carbon steel pipe shall be ASTM Standard A 53 Grade B,

Type E (electric resistance welded) or Type S (seamless); or

ASTM Standard A 106 Grade B (seamless). Standard A 53

Type F is not permitted.

Refrigeration piping design and fabrication should be in

accordance with the applicable sections of ASME B31.5 -

Refrigeration Piping and Heat Transfer Components for the

steel piping.

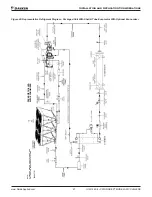

Table 10:

Sizing Guidelines for Upflow Lines

Recommended Horizontal or Downflow Suction Line Size

Nominal Circuit

Capacity

Estimated Line

TEL (ft)

Line Material

Suction Line

Size (Inches)

240

100

Steel

6

265

100

Steel

6

215

125

Steel

6

240

125

Steel

6

265

125

Steel

6

190

150

Steel

6

215

150

Steel

6

240

150

Steel

6

265

150

Steel

6

190

175

Steel

6

215

175

Steel

6

240

175

Steel

6

265

175

Steel

6

190

200

Steel

6

215

200

Steel

6

240

200

Steel

6

265

200

Steel

6

190

225

Steel

6

215

225

Steel

6

240

225

Steel

6

265

225

Steel

6

190

250

Steel

6

215

250

Steel

6

240

250

Steel

6

265

250

Steel

6

190

275

Steel

6

215

275

Steel

6

240

275

Steel

6

265

275

Steel

6

190

300

Steel

6

215

300

Steel

6

240

300

Steel

6

265

300

Steel

6

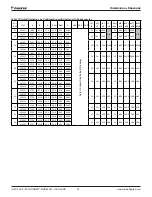

Recommended Upflow Suction Line Size

Nominal Circuit

Capacity

Line Material

Suction

Line

Size

(Inches)

Estimated Line

TEL (ft)

65

Copper

3 5/8

50

90

Copper

3 5/8

50

115

Copper

3 5/8

50

140

Copper

4 1/8

50

165

Copper

4 1/8

50

190

Copper

5 1/8

50

215

Copper

5 1/8

50

240

Copper

5 1/8

50

265

Copper

5 1/8

50

65

Copper

3 5/8

75

90

Copper

3 5/8

75

115

Copper

3 5/8

75

140

Copper

4 1/8

75

165

Copper

4 1/8

75

190

Copper

5 1/8

75

215

Copper

5 1/8

75

240

Copper

5 1/8

75

265

Copper

5 1/8

75