Unit Functions

www.DaikinApplied.com 57

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

Freeze Protection

To protect the evaporator from freezing, the evaporator pump

will start if the manual reset flow loss alarm is not active and

either of the following are true:

• LWT equal to or less than the Evap Freeze set point for at

least three seconds and LWT sensor fault is not active

• EWT equal to or less than the Evap Freeze set point for

at least three seconds and EWT sensor fault is not active

Freeze protection will end when manual reset flow loss alarm

is active or all of the following are true:

• LWT is at least 1.11°C (2°F) above the Evap Freeze set

point or LWT sensor fault is active

• EWT is at least 1.11°C (2°F) above the Evap Freeze set

point or EWT sensor fault is active

• Pump has been running for at least 15 minutes

Pump Selection

The pump output used when evaporator state is Run will be

determined by Evap Pump Control set point. This setting

allows the following configurations:

•

#1 only – Pump 1 will always be used

•

#2 only – Pump 2 will always be used

•

Auto – The primary pump is the one with the least run

hours, the other is used as a backup

•

#1 Primary – Pump 1 is used normally, with pump 2 as a

backup

•

#2 Primary – Pump 2 is used normally, with pump 1 as a

backup

Primary/Standby Pump Staging

The pump designated as primary will start first. If the

evaporator state is Start for a time greater than the recirculate

timeout set point and there is no flow, then the primary

pump will shut off and the standby pump will start. When the

evaporator is in the run state, if flow is lost for more than half of

the Flow Loss Delay set point value, the primary pump will shut

off and the standby pump will start. Once the standby pump

is started, the flow loss alarm logic will apply if flow cannot be

established in the evaporator start state, or if flow is lost in the

evaporator run state.

Auto Control

If auto pump control is selected, the primary/standby logic

above is still used. When the evaporator is not in the run state,

the run hours of the pumps will be compared. The pump with

the least hours will be designated as the primary at this time.

Leaving Water Temp (LWT) Reset

LWT Target

The evaporator LWT Target varies based on settings and

inputs and is selected as follows:

Table 51: LWT Targets Control Source

Available

Modes

Set Point

Control

Source

Set Point

Mode

Switch

BAS

Mode

Command

BAS LWT Target

Cool

Local

-

-

Cool LWT Set Point

Cool

Network

-

-

BAS Cool Set Point

Cool/Ice

Local

Off

-

Cool LWT Set Point

Cool/Ice

Local

On

-

Ice LWT Set Point

Cool/Ice

Network

-

Cool

BAS Cool Set Point

Cool/Ice

Network

-

Ice

BAS Ice Set Point

Ice

Local

-

Ice LWT Set Point

Ice

Network

-

-

BAS Ice Set Point

The base LWT target may be reset to a higher value if the

unit is in Cool Mode and it is configured for a reset. The type

of reset to be used is determined by the LWT Reset Type set

point.

When the active reset increases, the Active LWT Target is

changed at a rate of 0.1°C (0.18°F) every 10 seconds. When

the active reset decreases, the Active LWT Target is changed

all at once.

After resets are applied, the LWT target can never exceed a

value of 21.12°C (70°F). Since the Cool LWT set point can be

set as high as 21.12°C, the amount of reset may be limited in

order to meet this requirement to clamp the active LWT target

to 21.12°C.

Reset Type – None

The Active LWT target is set equal to the base LWT target.

4-20 mA External Signal Reset

The Active LWT target is adjusted by the 4-20 mA reset analog

input. Parameters used:

1. Max Reset set point

2. LWT Reset signal

Reset is 0 if the reset signal is less than or equal to 4 mA.

Reset is equal to the Max Reset Delta T set point if the reset

signal equals or exceeds 20 mA. The amount of reset will vary

linearly between these extremes if the reset signal is between

4 mA and 20 mA. An example of the operation of 4-20 mA reset

in Cool Mode follows.

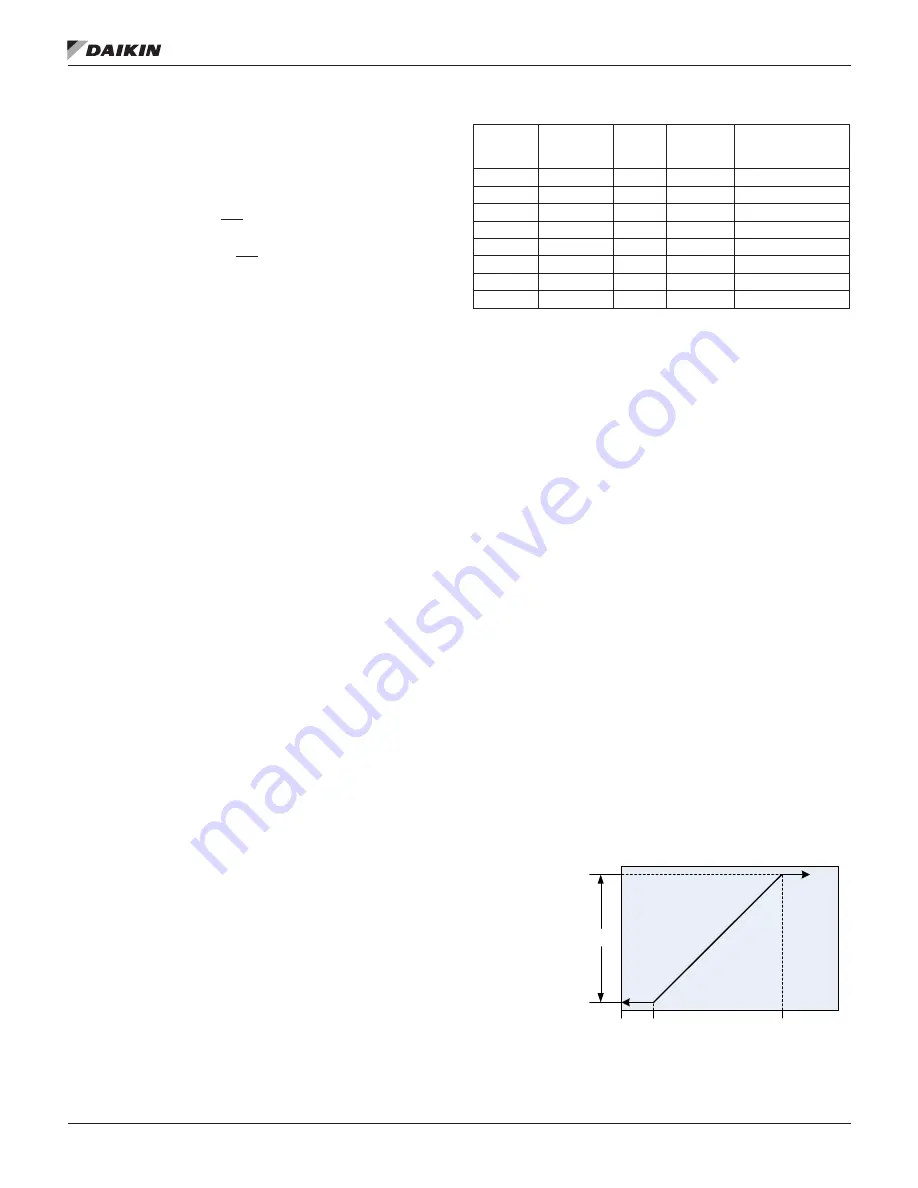

Figure 69: 4-20 mA Reset - Cool Mode

Max Reset

Base LWT

Max

Reset

Base LWT

Target

20

0

Reset Signal (mA)

Active

LWT

Target

4

4

-

20 mA Reset