Circuit Functions

www.DaikinApplied.com 65

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

Capacity Control

The compressor will vary capacity via changes to the motor

speed (frequency).

Auto Capacity Control

The normal speed change is 1 Hz for all compressor

configurations.

Circuit State = Off

- Speed command is 0 Hz.

Circuit State = Preopen

- Speed command is set to the

minimum for the configuration.

Circuit State = Start

- Immediately after starting, the

compressor speed will be set to the minimum for the

configuration and held there while circuit state is Start.

Circuit State = Run

- After the circuit enters the Run state,

changes to the speed are performed based on load and unload

commands coming from the unit capacity control logic (see

Unit Capacity Control section). The speed is constrained to a

range from the minimum based on the configuration up to the

Compressor Maximum Speed set point.

When a capacity increase occurs, a time delay starts; and

when a capacity decrease occurs, a separate time delay starts.

While either of these delays is active, no normal capacity

changes will occur. The load and unload delay times are

calculated values.

Circuit State = Pumpdown

- Speed command will drop 2 Hz

every second until reaching the minimum for the configuration.

Manual Speed Control

The speed of the compressor may be controlled manually.

Manual speed control is enabled via a set point with choices

of Auto or Manual. Another set point allows setting the

compressor speed. However, the resulting compressor speed

is still limited to the range from the minimum speed based on

configuration up to the Compressor Maximum Speed set point.

The compressor speed will be stepped up or down until it is

equal to the speed that corresponds to the manual speed set

point. Changes to the speed will be made as fast as allowed by

the calculated load and unload delays. Speed control may be

set to Manual only when circuit state is Start or Run.

Capacity control shall revert back to automatic control if either:

• circuit state changes from Start or Run to another state

• speed control has been set to Manual for four hours

• an unload event occurs on the circuit

Load and Unload Delay

LWT Error determines the delays for load and unload

commands.

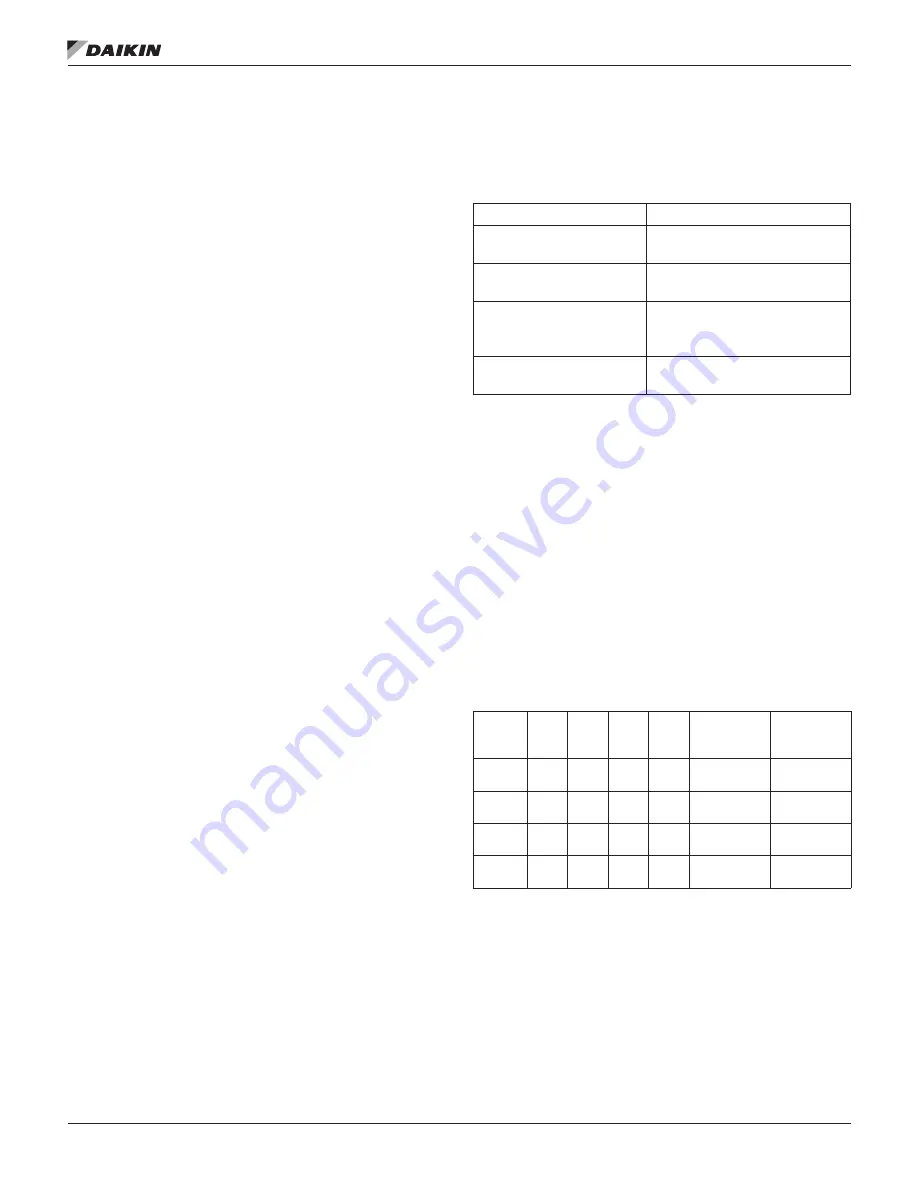

Table 54: Load and Unload Delay Conditions

LWT Error

Delay

LWT Error > Startup Delta

T set point

Load command delay is 5

seconds

0.1°C ≤ LWT Error ≤

Startup Delta T set point

Load command delay will vary

from 5 seconds to 10 seconds

– (Stage Down Delta T

set point) ≤ LWT Error ≤

-0.1°C

Unload command delay will

vary from 3 seconds to 6

seconds

LWT Error < -(Stage Down

Delta T set point)

Unload command delay is 3

seconds

VR Solenoid Valve Control

There are three solenoid valves for changing volume ratio of

the compressor:

• 50 VR solenoid valve

• 75 VR solenoid valve

• 100 VR solenoid valve

The compressor should start with all three solenoid valves off.

After compressor has been running for at least 20 seconds, the

control logic will “stage” the solenoid valves.

which VR solenoid valves are on at each stage as well as

stage up and stage down conditions. These staging conditions

must be active for 30 seconds to trigger each stage up or

down.

Table 55: VR Solenoid Valve Control Stages

Stage

VR

50

VR

SV

75

VR

SV

100

VR

SV

Stage Up

Condition

Stage Down

Condition

0

1.6

Off

Off

Off

Pressure

Ratio > 2.10

n/a

1

1.8

On

Off

Off

Pressure

Ratio > 2.85

Pressure

Ratio < 1.90

2

2.4

Off

On

Off

Pressure

Ratio > 3.85

Pressure

Ratio < 2.65

3

3.1

On

On

On

n/a

Pressure

Ratio < 3.65

When the circuit state becomes Pumpdown or Off, all VR

solenoids should be turned off.